A kind of mnooh nanorod denitration catalyst and preparation method thereof

A denitrification catalyst and nanorod technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of increased denitrification costs in power plants, short service life of catalysts, catalytic clogging and passivation, and achieve catalytic activity And the effect of enhanced selectivity, enhanced catalytic activity, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

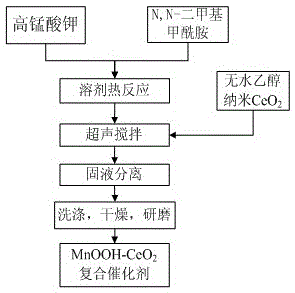

[0025] Take 1g of potassium permanganate and 20ml of N,N-dimethylformamide into an autoclave, and conduct a solvothermal reaction at a temperature of 100°C for 2h to obtain MnOOH nanorods. Take 1gCeO 2 Particles and 5ml of absolute ethanol were added to the reacted solution, and ultrasonically stirred for 3h to make the CeO 2 Fully loaded with MnOOH nanorods. Then, the reacted product was subjected to solid-liquid separation by centrifugation, and the separated solid was washed with distilled water and acetone in turn, and finally dried at 30°C for 1 hour to obtain the MnOOH nanorod denitration catalyst, MnOOH-CeO 2 Composite catalyst. The obtained final product was ground, and 0.2 g was taken for denitrification experiment.

[0026] Put 0.2g of the prepared catalyst into a quartz tube reactor for denitrification experiment. The flue gas reaction conditions are: the total gas flow rate is 1L / min, C O2= 4%, C CO2 =12%, N 2 =50ml, NH 3 =50ml, NH 3 / NO=1:1,N 2 As a bala...

Embodiment 2

[0028] Take 1g of potassium permanganate and 50ml of N,N-dimethylformamide into an autoclave, and conduct a solvothermal reaction at a temperature of 150°C for 2h to obtain MnOOH nanorods. Take 0.5gCeO 2 Particles and 2ml of absolute ethanol were added to the reacted solution, and ultrasonically stirred for 3.5h to make the CeO 2 Fully loaded with MnOOH nanorods. Then, the reacted product was subjected to solid-liquid separation by centrifugation, and the separated solid was washed with distilled water and acetone in sequence, and finally dried at 60°C for 2 hours to obtain the MnOOH nanorod denitration catalyst, MnOOH-CeO 2 Composite catalyst. The obtained final product was ground, and 0.2 g was taken for denitrification experiment.

[0029] Put 0.2g of the prepared catalyst into a quartz tube reactor for denitrification experiment. The flue gas reaction conditions are: the total gas flow rate is 1L / min, C O2= 4%, C CO2 =12%,N 2 =50ml, NH 3 =50ml, NH 3 / NO=1:1,N 2 A...

Embodiment 3

[0031] Take 1g of potassium permanganate and 75ml of N,N-dimethylformamide, put them into an autoclave, and conduct a solvothermal reaction at a temperature of 175°C for 4h to obtain MnOOH nanorods. Take 0.25gCeO 2 Particles and 1ml of absolute ethanol were added to the reacted solution, and ultrasonically stirred for 4h to make the CeO 2 Fully loaded with MnOOH nanorods. Then, the reacted product was subjected to solid-liquid separation by centrifugation, and the separated solid was washed with distilled water and acetone in turn, and finally dried at 80°C for 2.5 hours to obtain the MnOOH nanorod denitration catalyst, namely MnOOH-CeO 2 Composite catalyst. The obtained final product was ground, and 0.2 g was taken for denitrification experiment.

[0032]Put 0.2g of the prepared catalyst into a quartz tube reactor for denitrification experiment. The flue gas reaction conditions are: the total gas flow rate is 1L / min, C O2= 4%, C CO2 =12%,N 2 =50ml, NH 3 =50ml, NH 3 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com