Preparation method and application of a wide temperature window denitration catalyst

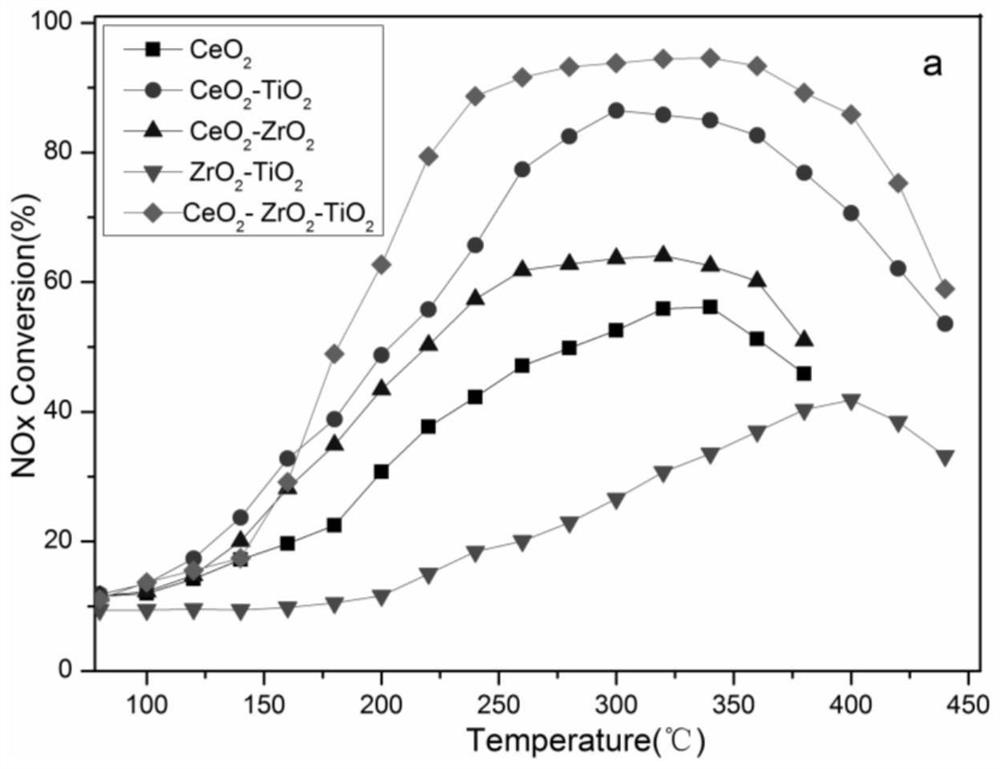

A denitrification catalyst and wide temperature technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve the problems of narrow temperature window, environmental hazards, poor environmental adaptability, etc., and achieve wide temperature Window, improvement of uniformity and dispersion, effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

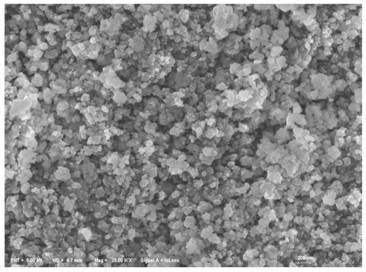

Embodiment 1

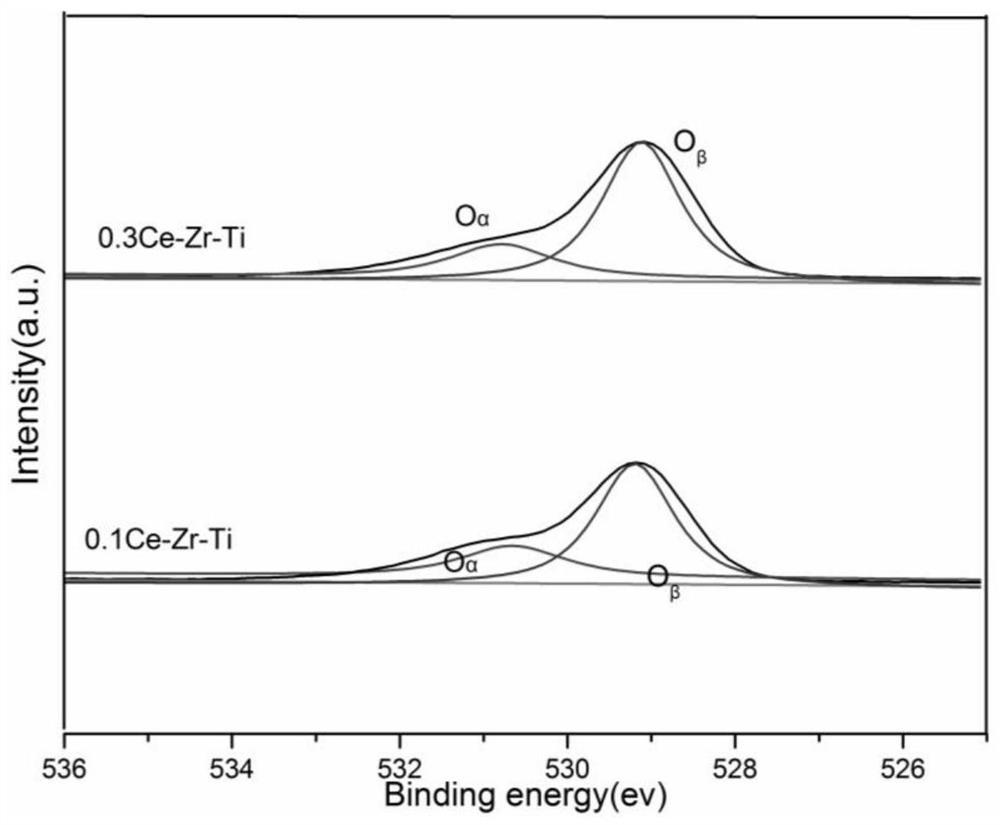

[0035]A wide temperature window denitration catalyst is composed of Ce, Zr and Ti mixed according to the molar ratio of 0.1:1:1. It is prepared by the following method: 1) First, weigh 4.2932g of zirconium nitrate pentahydrate, 1.9595g of sulfuric acid Titanium oxide and 0.4312g cerium nitrate hexahydrate were mixed and dissolved in 250mL deionized water, stirred with a magnetic stirrer for 2 to 3 hours until the solution changed from turbid to clear, and mixed solution A was obtained; 2) the amount of glucose was the total molar ratio of Ce:Zr:Ti 2.5 times the molar ratio, weighed 10.4039g glucose and dissolved it in 100mL deionized water to obtain liquid B; mixed solution B with clear liquid mixed liquid A containing cerium, zirconium and titanium to obtain mixed liquid C, and continued to stir for 30 minutes; 3) Configure the concentration 1mol / L ammonia solution, add 1mol / L ammonia solution dropwise to mixed solution C, and control the pH at 10 to obtain emulsion D, transfe...

Embodiment 2

[0038] A wide temperature window denitration catalyst, which is composed of Ce, Zr and Ti according to the molar ratio of 0.2:1:1, is prepared by the following method: 1) First, weigh 4.2932g zirconium nitrate pentahydrate, 1.9595g sulfuric acid Titanium oxide and 0.8682g of cerium nitrate hexahydrate were mixed and dissolved in 250mL of deionized water, stirred with a magnetic stirrer for 2 to 3 hours until the solution changed from turbid to clear, and mixed solution A was obtained; 2) the amount of glucose was the total molar ratio of Ce:Zr:Ti 2.5 times the molar ratio, weighed 10.4039g glucose and dissolved it in 100mL deionized water to obtain liquid B; mixed solution B with clear liquid mixed liquid A containing cerium, zirconium and titanium to obtain mixed liquid C, and continued to stir for 30 minutes; 3) Configure the concentration 1mol / L ammonia solution, add 1mol / L ammonia solution dropwise to mixed solution C, and control the pH at 10 to obtain emulsion D, transfer...

Embodiment 3

[0041] A wide temperature window denitration catalyst is composed of Ce, Zr and Ti mixed according to the molar ratio of 0.3:1:1. It is prepared by the following method: 1) First, weigh 4.2932g of zirconium nitrate pentahydrate, 1.9595g of sulfuric acid Titanium oxide and 1.3024g cerium nitrate hexahydrate were mixed and dissolved in 250mL deionized water, and stirred with a magnetic stirrer for 2 to 3 hours until the solution changed from turbid to clear to obtain mixed solution A; 2) the amount of glucose was the total molar ratio of Ce:Zr:Ti 2.5 times the molar ratio, weighed 11.3948g glucose and dissolved it in 100mL deionized water to obtain liquid B; mixed solution B with clear liquid mixed liquid A containing cerium, zirconium and titanium to obtain mixed liquid C, and continued to stir for 30 minutes; 3) Configure the concentration 1mol / L ammonia solution, add 1mol / L ammonia solution dropwise to mixed solution C, and control the pH at 10 to obtain emulsion D, transfer t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com