Complete equipment for soil remediation by leaching method

A technology of soil remediation and a complete set of equipment, which is applied in the field of contaminated soil remediation, can solve the problems of long remediation time, difficulty, and slow speed of pollutants, and achieve the effects of low treatment cost, wide application range and reasonable process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings:

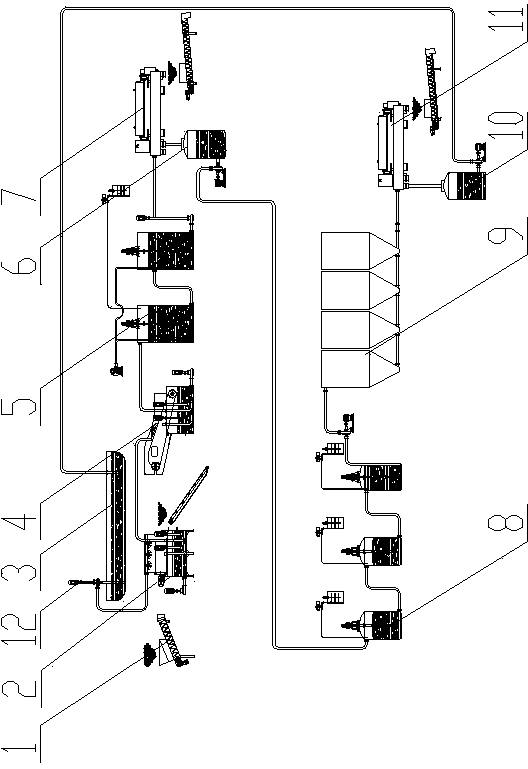

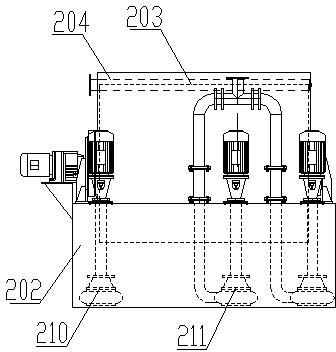

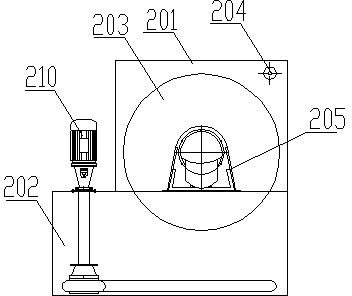

[0025] Such as figure 1 As shown, the complete set of leaching soil remediation equipment includes screw conveyor 1, preliminary screening separator 2, fine screening separator 4, acid adding stirring tank 5, centrifugal separator 7, sewage tank 6, alkali adding stirring Tank 8, sedimentation tank 9, and filter press 11. The liquid phase outlet of the centrifugal separator is connected to the sewage tank 6, and the solid phase outlet of the centrifugal separator is connected to the input end of the screw conveyor; the sewage tank is connected to the alkali adding stirring tank 8 via a mud pump. The sedimentation tank 9 is a four-stage series sedimentation tank, the last stage of the sedimentation tank is connected to the filter press 11, the water phase outlet of the filter press is connected to the clean water bucket 10, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com