One-step preparation method of three-dimensional mesoporous nanometer cage-shaped carbon material for super capacitor

A technology of supercapacitors and nano-cages, applied in nano-carbon, nano-technology for materials and surface science, nano-technology, etc., can solve the problems of complex preparation process and high production cost of nano-carbon materials, and shorten the activation time and cost. Inexpensive, accelerated heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

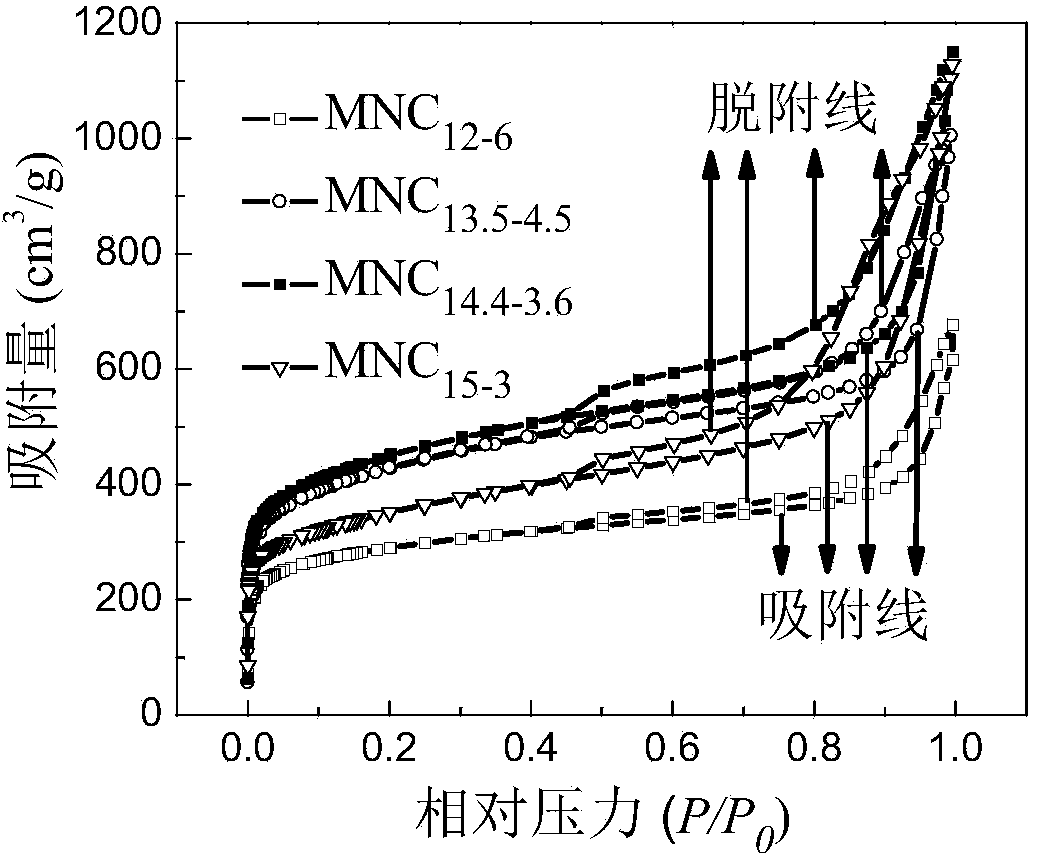

[0018] Example 1: Three-dimensional mesoporous nanocage carbon material MNC 12-6 Concrete preparation process is as follows:

[0019] According to the method described in the literature (Microporous and Mesoporous Materials58 (2003) 105-114), Zn code-named MOF-5 was prepared 4 O(BDC) 3 . Weigh 12g Zn 4 O(BDC) 3 Put it into a mortar, then add 6g of solid potassium hydroxide, mix and grind the two raw materials for 1 to 2 hours, then transfer the resulting mixture to a ceramic crucible, place it in a microwave reactor, set the microwave power to 600W, and activate the microwave The time is 20 minutes, microwave heating and activation is carried out in a flowing nitrogen atmosphere, the activated product is cooled to room temperature and then taken out, the product is ground and put into a beaker, after pickling, hot distilled water washing and drying, a three-dimensional medium for supercapacitors is obtained. Porous nanocage carbon materials. The resulting three-dimension...

Embodiment 2

[0020] Example 2: Three-dimensional mesoporous nanocage carbon material MNC 13.5-4.5 Concrete preparation process is as follows:

[0021] Implementation according to the same method as in Example 1, the difference is that Zn is weighed 4 O(BDC) 3 The mass of is 13.5g, and the mass of solid potassium hydroxide is 4.5g. The resulting three-dimensional mesoporous nanocage carbon material labeled as MNC 13.5-4.5 .

Embodiment 3

[0022] Example 3: Three-dimensional mesoporous nanocage carbon material MNC 14.4-3.6 Concrete preparation process is as follows:

[0023] Implementation according to the same method as in Example 1, the difference is that Zn is weighed 4 O(BDC) 3 The mass of is 14.4g, and the mass of solid potassium hydroxide is 3.6g. The resulting three-dimensional mesoporous nanocage carbon material labeled as MNC 14.4-3.6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com