Low temperature cold-pressing production technology for tea oil

A production process and low-temperature technology, applied in the direction of fat oil/fat production, fat generation, fat oil/fat refining, etc., can solve the problems of high energy consumption, dark tea oil color, high production cost, etc., and achieve low equipment investment, simple process, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

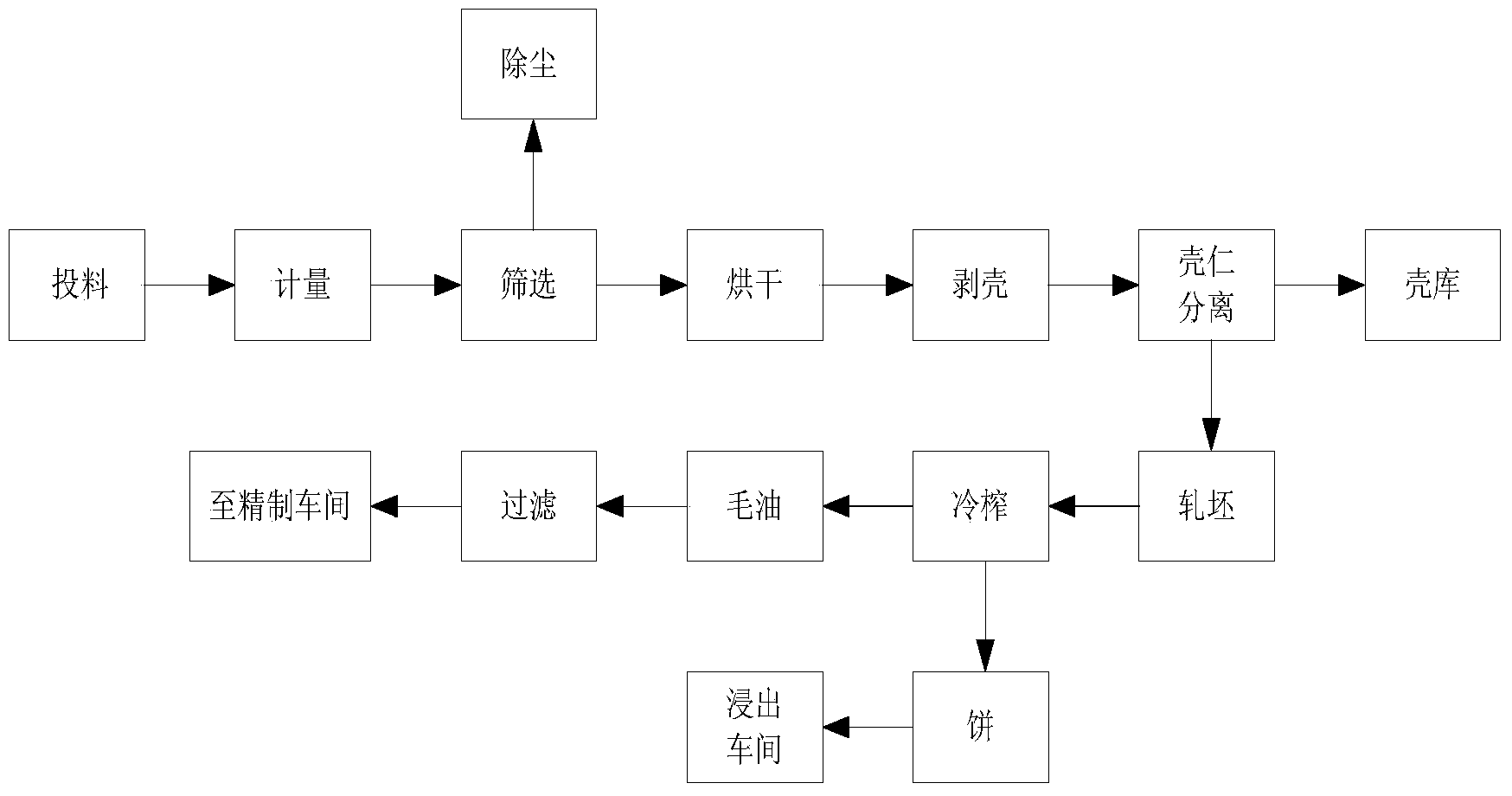

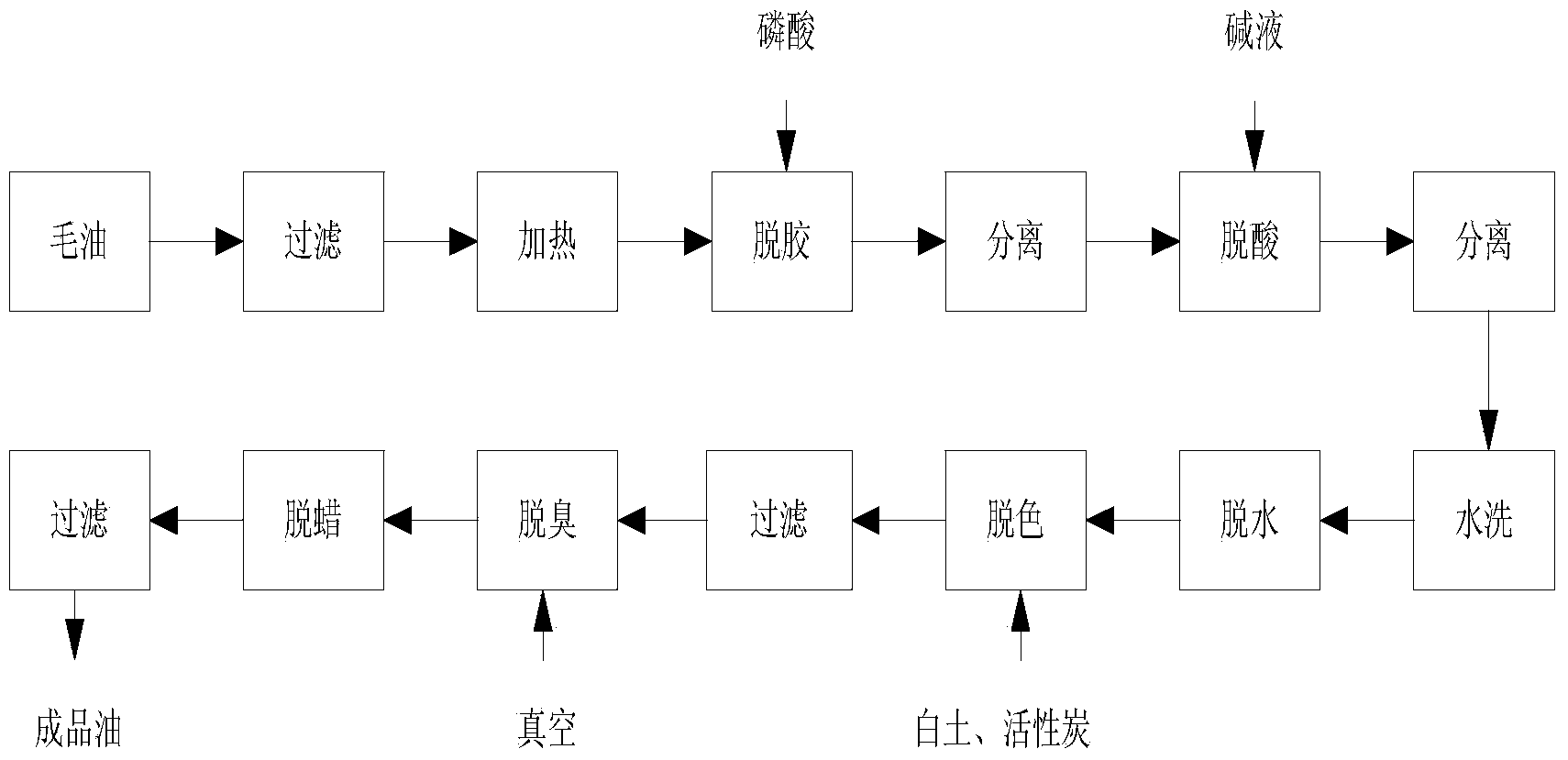

[0032] A low-temperature cold-pressing production process of camellia oil, comprising the following steps:

[0033] (1) Pretreatment cold pressing process

[0034] Camellia oleifera seeds are cleaned by using a combined sieve, which can sieve out large impurities, small impurities, heavy impurities, light impurities and dust. The cleaned camellia seeds enter the sheller, and the shelled kernel and shell mixture are sent to the kernel and shell Separation and sieve separation, the separated camellia seed kernels are rolled into a 0.4mm thick billet and cracked by a rolling mill after iron removal, and the billet is sent to a flat-bottomed frying pan for steaming and frying. It is hot to the touch, when the temperature is 115°C and the moisture content is 3%, it can be squeezed;

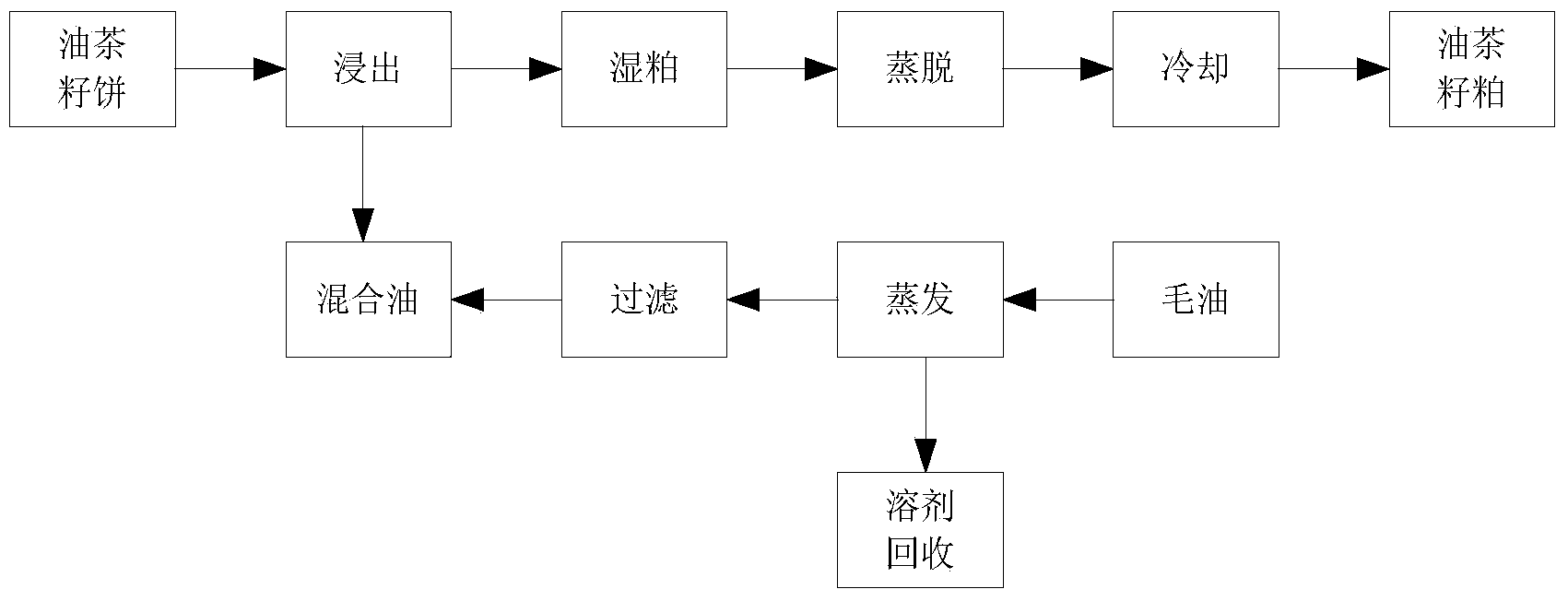

[0035] Send the steamed and fried raw material into a cold press for pressing. The temperature in the boring does not exceed 80°C during pressing. The squeezed cake is sent to the leaching workshop fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com