A crystal selector for preparing directional solidification material and its application

A technology of directional solidification and crystal selector, applied in self-solidification, crystal growth, single crystal growth, etc., can solve the problems of equipment design difficulty, increased manufacturing cost, complicated manufacturing process, poor repeatability, etc., and achieve single crystal output The effect of high efficiency, low cost and high product versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

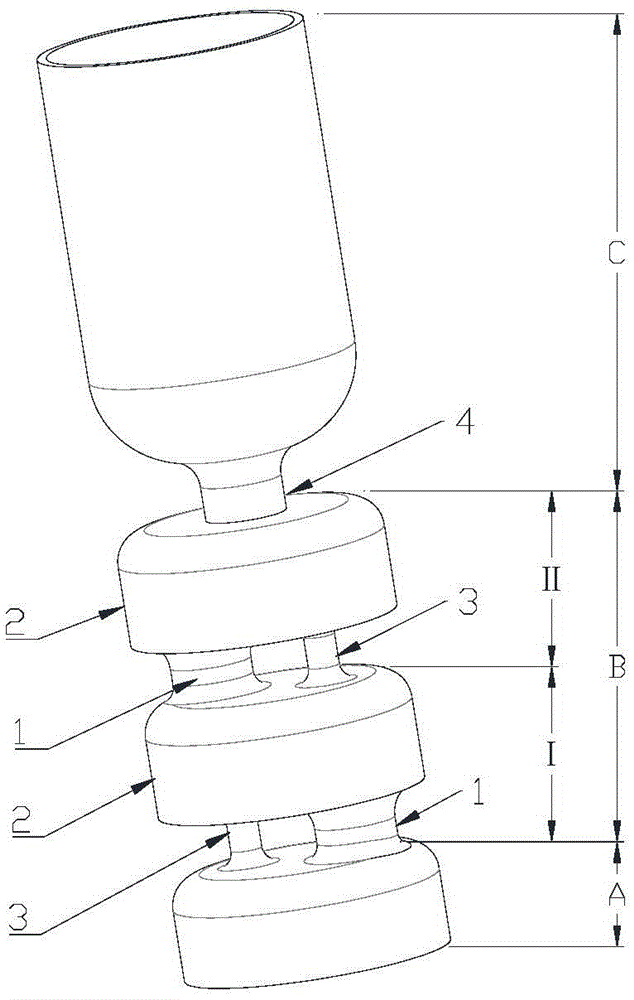

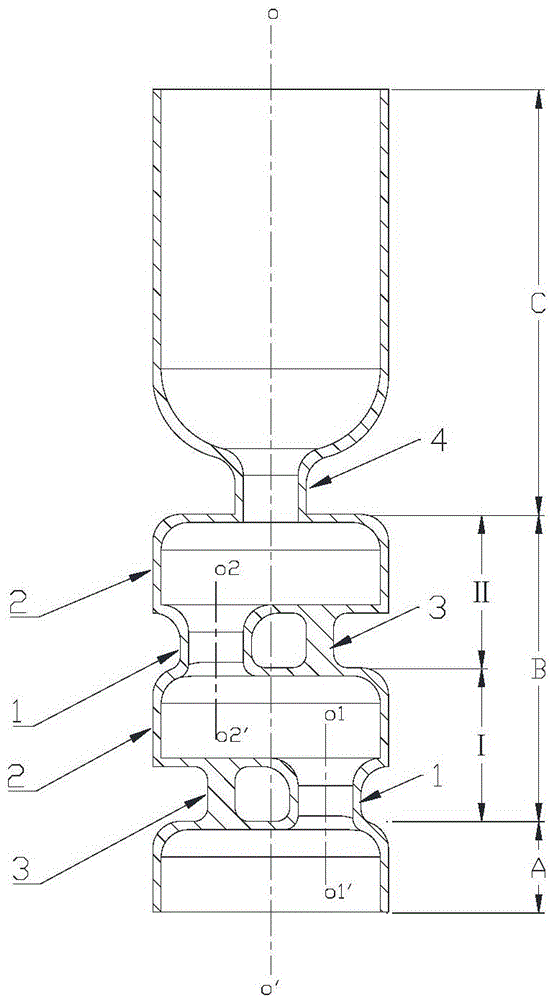

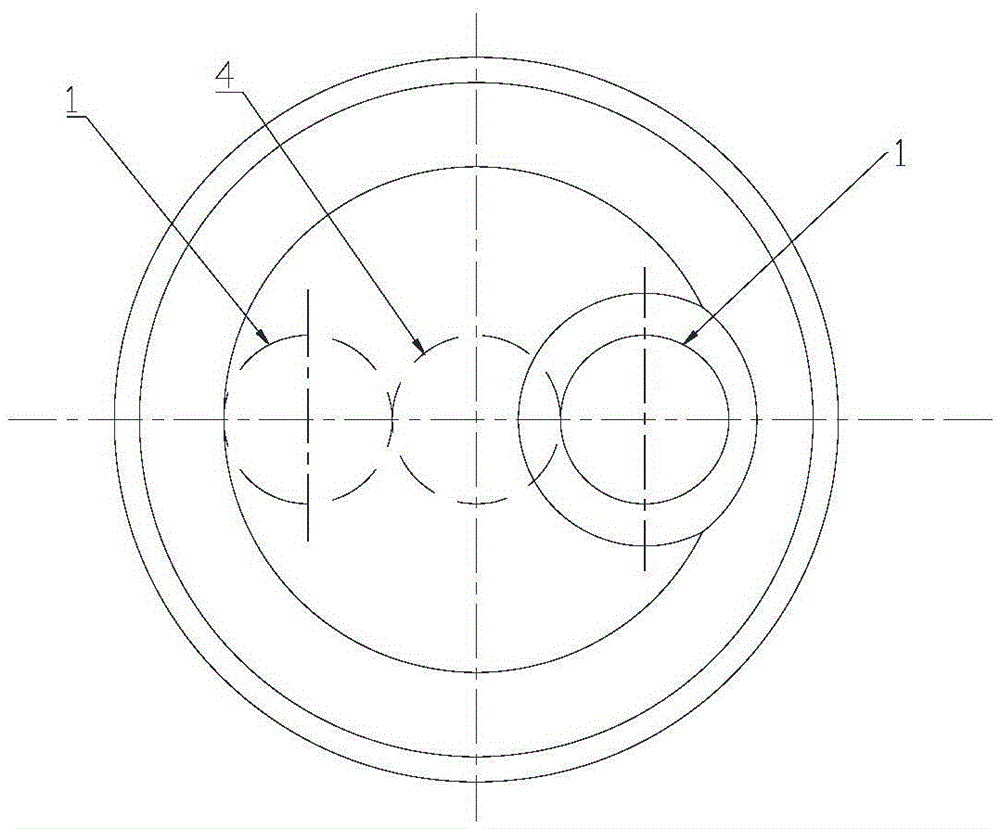

[0028] figure 1 It is a three-dimensional schematic diagram of a cylindrical cross-axis necking crystal selector, figure 2 is its cross-sectional diagram, image 3 is its bottom view. like figure 1 combine figure 2 As shown, the different-axis necking crystal selector of the present invention is a hollow mold, which is made by compression molding at one time, and the material is quartz, and the wall thickness is 3mm. The crystal selector includes seeding section A, crystal selection section B and shaping section C.

[0029] The seeding section A is a hollow cylinder, and its bottom is connected and fixed to the cooling seat (not shown) of the directional solidification device, and its bottom diameter is 80mm. The shape of the seeding segment A can match the shape of the directional solidification cooling base, including circular, oval, rectangular and other shapes.

[0030] The crystal selection section B is located above the seeding section A, and consists of two neck...

Embodiment 2

[0034] Figure 4 and Figure 5 They are the three-dimensional schematic diagram and the cross-sectional schematic diagram of the blade-shaped two-stage cross-axis necking crystal selector, respectively, Image 6 for its top view. like Figure 4 to combine Figure 5 As shown, the structure and size of seeding segment A and crystal selection segment B are the same as in embodiment 1, except that the main body of forming segment C is the blade shape of an approximate engine (such as Image 6 shown), but for the convenience of pouring, the top of the forming section C is still round, and the transition between them is designed to be smooth. The usage method is similar to that of Embodiment 1, and will not be repeated here. The crystal selector of this embodiment is used to produce superalloys used in aero-engines.

Embodiment 3

[0036] Figure 7 and Figure 8 They are the three-dimensional schematic diagram and the cross-sectional schematic diagram of the square column-shaped 4-stage cross-axis necking crystal selector, Figure 9 for its top view. As shown in the figure, the structural composition is similar to that of Example 1, except that the selected crystal section B is composed of 4 subunits, and the axis of each adjacent unit necking section is in the vertical projection plane and the projection point of the central axis oo' The angle of the connecting line is 90 degrees. The projection of the necking section 1 of the 4 subunits is as follows Figure 9 As shown, this has a better crystal selection effect. In addition, the diameter of the selected crystal section A is 100mm, the diameter of the narrowest part of the inner surface of the necking section 1 is 30mm, and the diameter of the narrowest part of the support column 2 is 24mm. The main body of the forming section C is a square column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com