A high withstand voltage, low leakage, high polarization strength bismuth ferrite thin film and preparation method thereof

A polarization, bismuth ferrite technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problem of making bismuth ferrite thin films difficult to prepare, difficult to prepare pure-phase thin films, and easy to generate oxygen vacancy ions. and other problems, to achieve the effect of favorable industrialization promotion, good compactness and good pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

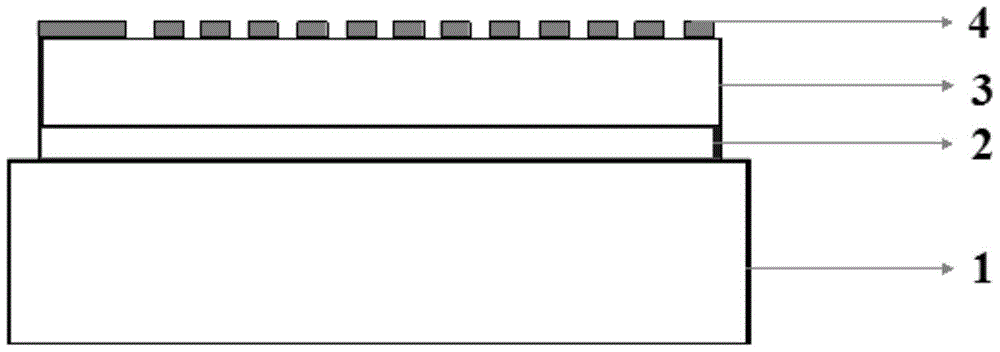

[0036] A method for preparing a bismuth ferrite thin film with high withstand voltage, low electric leakage and high polarization strength, comprising the following steps:

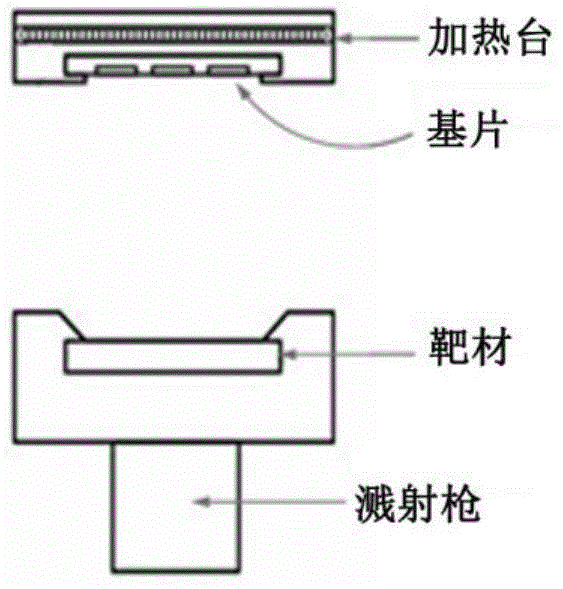

[0037] (a) Treatment of the substrate

[0038] Cleaning and mounting: LaAlO with (111) orientation 3 For a single crystal substrate, the substrate is ultrasonically cleaned with acetone and absolute ethanol in sequence, rinsed with deionized water, dried with high-purity nitrogen, fixed on the sample tray, and loaded into the sample tray of the vacuum coating chamber. On the tray rack, close the vacuum chamber, pump the system with a mechanical pump to achieve a low vacuum ~ 10 -1 Pa, and then evacuated to ~10 by molecular pump -4 Pa.

[0039] Heating: Introduce argon gas into the system, keep the air pressure at 1.2-1.4Pa, and then heat the substrate to a temperature of 500-600°C.

[0040] (b) Preparation of conductive oxide thin film bottom electrode

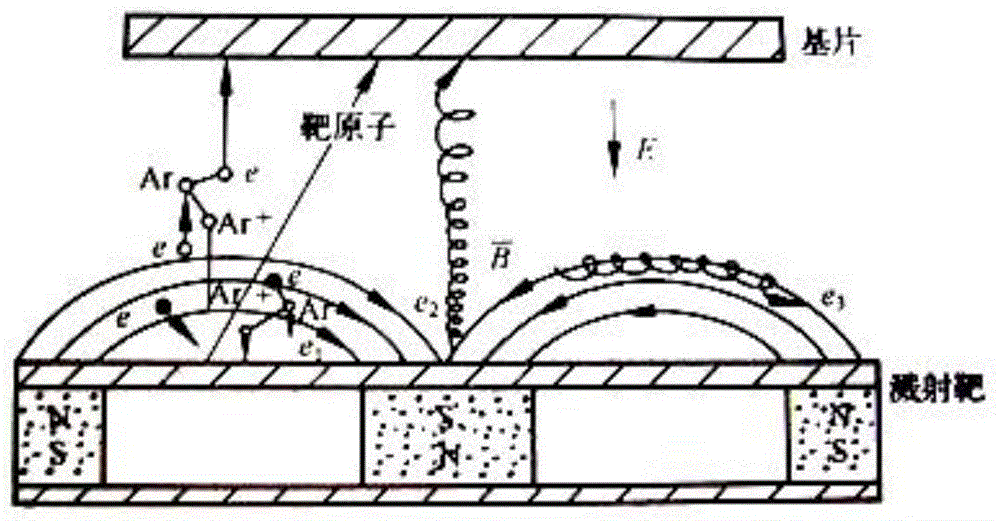

[0041] Perovskite LaNiO 3 The target is comple...

Embodiment 2

[0048] The difference between this example and Example 1 is that (111) oriented SrTiO is used in step (a) 3 single crystal substrate. Other steps and parameters are the same as in Example 1. The obtained BiFeO in this embodiment 3 The XRD test results of the film are as follows image 3 As shown, BiFeO 3 The thin film has a rhombohedral phase (111) preferred orientation. After performance testing, the ferroelectric properties of the obtained thin film are significantly improved, and the pressure resistance is significantly improved. The hysteresis loop is as follows: Figure 4 shown.

Embodiment 3

[0050] A method for preparing a bismuth ferrite thin film with high withstand voltage, low electric leakage and high polarization strength, comprising the following steps:

[0051] (a) Treatment of the substrate

[0052] Cleaning and mounting: LaAlO with (111) orientation 3 For a single crystal substrate, the substrate is ultrasonically cleaned with acetone and absolute ethanol in sequence, rinsed with deionized water, dried with high-purity nitrogen, fixed on the sample tray, and loaded into the sample tray of the vacuum coating chamber. On the tray rack, close the vacuum chamber, pump the system with a mechanical pump to achieve a low vacuum ~ 10 -1 Pa, and then evacuated to ~10 by molecular pump -4 Pa.

[0053] Heating: Introduce argon gas into the system, keep the air pressure at 2Pa, and then heat the substrate to reach a temperature of 600-700°C.

[0054] (b) Preparation of conductive oxide thin film bottom electrode

[0055] Perovskite LaNiO 3 The target is comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com