Vitamin D calcium chewable tablet for calcium supplementation of children and preparation method thereof

A chewable tablet and calcium supplement technology, applied in the field of medicine, can solve the problems of difficulty in taking, low utilization rate, etc., and achieve the effects of simple process, low production cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

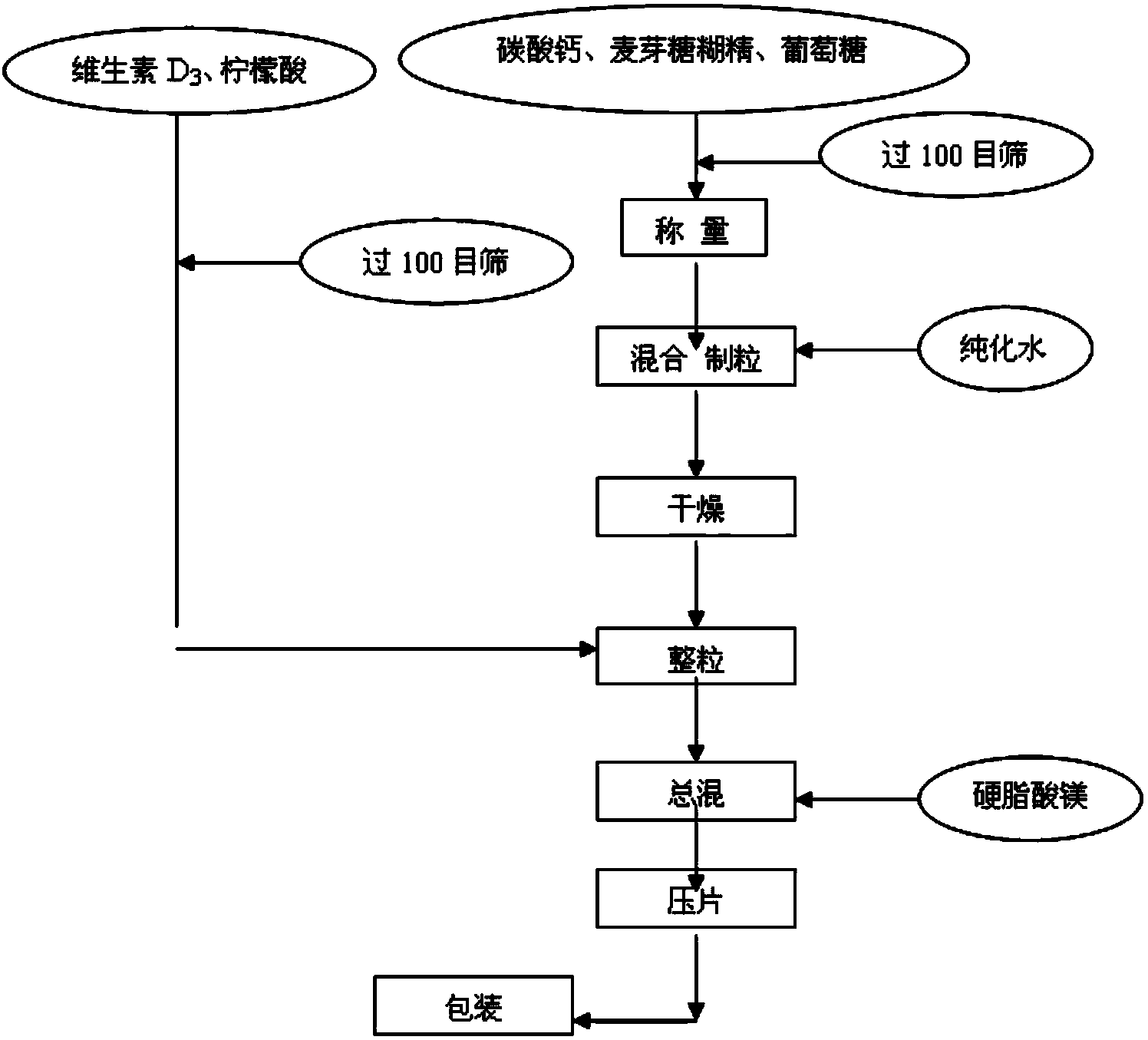

Method used

Image

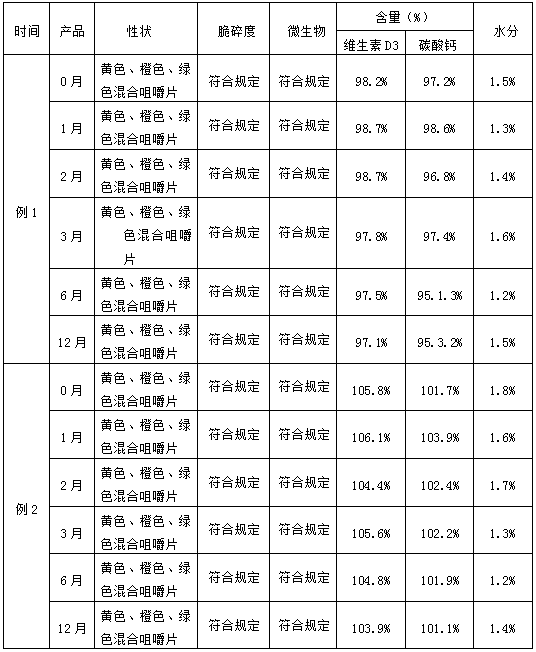

Examples

Embodiment 1

[0052] Mix by weight:

[0054] Vitamin D 3 Powder 0.08%

[0055] Sorbitol 12%

[0056] Glucose 12%

[0057] Maltodextrin 15%

[0058] Citrate 0.8%

[0059] Magnesium Stearate 1.8%

[0060] Lemon essence 1.2%

[0061] Purified water 70ml;

[0062] The required raw materials and auxiliary materials have passed the inspection and passed through a 100-mesh sieve for later use. Blend: Vitamin D 3 Powder and citric acid are mixed evenly, and are mixed by equal addition method. Preparation of soft materials: Weigh the prescribed amount of calcium carbonate, maltodextrin and glucose, put them in a high-efficiency wet granulator, and mix them evenly; add purified water as a wetting agent to prepare soft materials. Granulation and drying: use 18-mesh sieve to granulate, dry in an oven at 45°C-65°C, and control the moisture content at 2% to 4%. Grain granulation and blending: After drying, the granules are granulated with an 18-mesh sieve, and c...

Embodiment 2

[0064] Mix by weight:

[0066] Vitamin D 3 Powder 0.1%

[0067] Sorbitol 10%

[0068] Glucose 15%

[0069] Maltodextrin 10%

[0070] Citrate 1.5%

[0071] Magnesium Stearate 1.2%

[0072] Lemon essence 1.5%

[0073] Purified water 90ml;

[0074] The required raw materials and auxiliary materials have passed the inspection and passed through a 100-mesh sieve for later use. Blend: Vitamin D 3 Powder and citric acid are mixed evenly, and are mixed by equal addition method. Preparation of soft materials: Weigh the prescribed amount of calcium carbonate, maltodextrin and glucose, put them in a high-efficiency wet granulator, and mix them evenly; add purified water as a wetting agent to prepare soft materials. Granulation and drying: use 18-mesh sieve to granulate, dry in an oven at 45°C-65°C, and control the moisture at 2%-4. Grain granulation and blending: After drying, the granules are granulated with an 18-mesh sieve, and citric acid and ...

Embodiment 3

[0076] Mix by weight:

[0078] Vitamin D 3 Powder 0.12%

[0079] Sorbitol 12%

[0080] Glucose 10%

[0081] Maltodextrin 8%

[0082] Citrate 0.8%

[0083] Magnesium Stearate 2.0%

[0084] Lemon essence 0.5%

[0085] Purified water 80ml;

[0086] The required raw materials and auxiliary materials have passed the inspection and passed through a 100-mesh sieve for later use. Blend: Vitamin D 3 Powder and citric acid are mixed evenly, and are mixed by equal addition method. Preparation of soft materials: Weigh the prescribed amount of calcium carbonate, maltodextrin and glucose, put them in a high-efficiency wet granulator, and mix them evenly; add purified water as a wetting agent to prepare soft materials. Granulation and drying: use 18-mesh sieve to granulate, dry in an oven at 45°C-65°C, and control the moisture at 2%-4. Grain granulation and blending: After drying, the granules are granulated with an 18-mesh sieve, and citric acid an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com