Defluorination and desulfuration dust removal device and technology

A technology of desulfurization, dust removal and defluorination, which is applied in the direction of combination device, liquid separation agent, and dispersed particle separation, can solve the problems of easy blockage of the system, high environmental protection operation cost, inconvenience, etc., and achieve the goal of prolonging the chemical reaction time and improving the effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, a defluorination, desulfurization and dedusting device for purifying dusty gas proposed according to the present invention and craft. Its specific implementation, structure, feature and effect thereof are described in detail as follows.

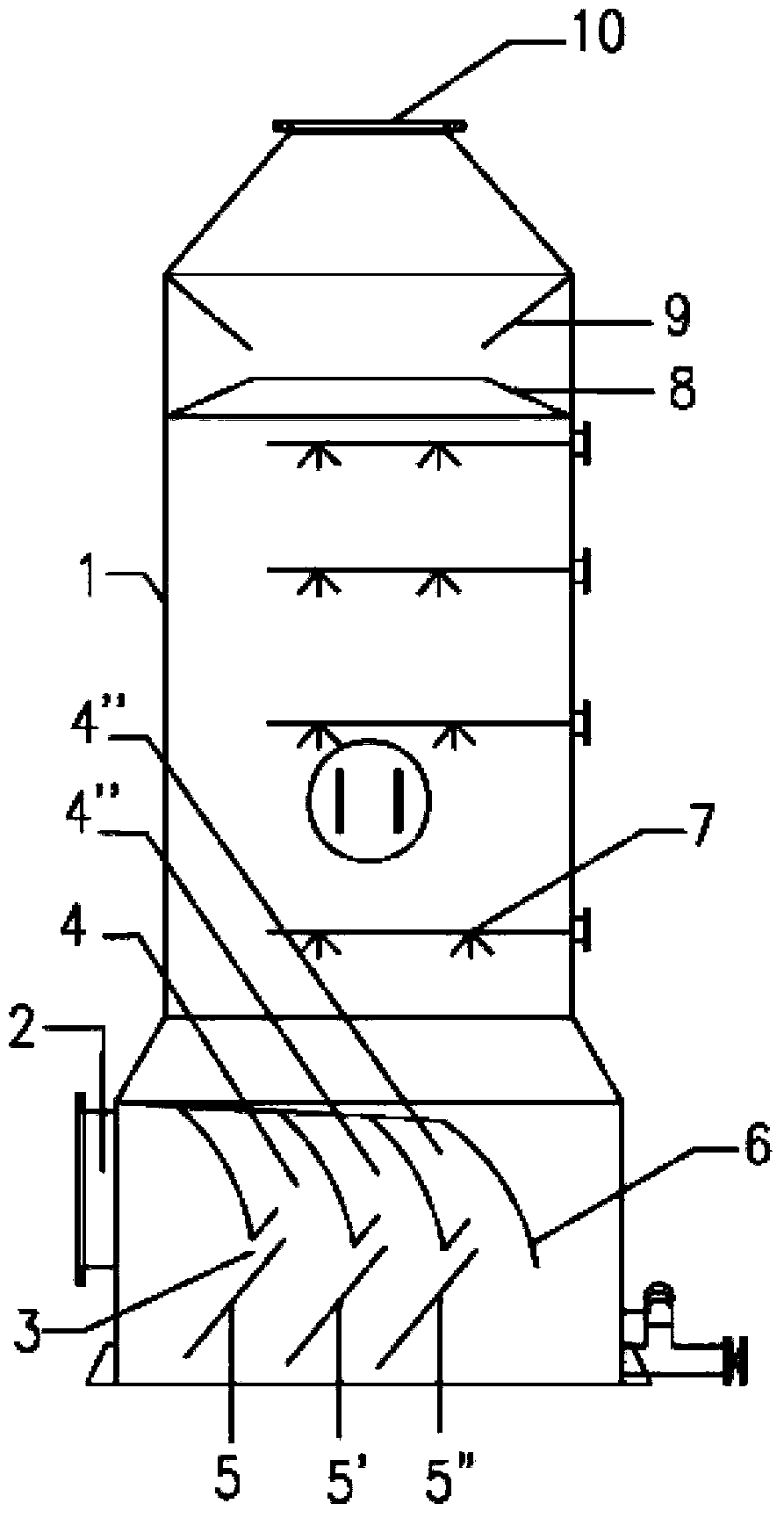

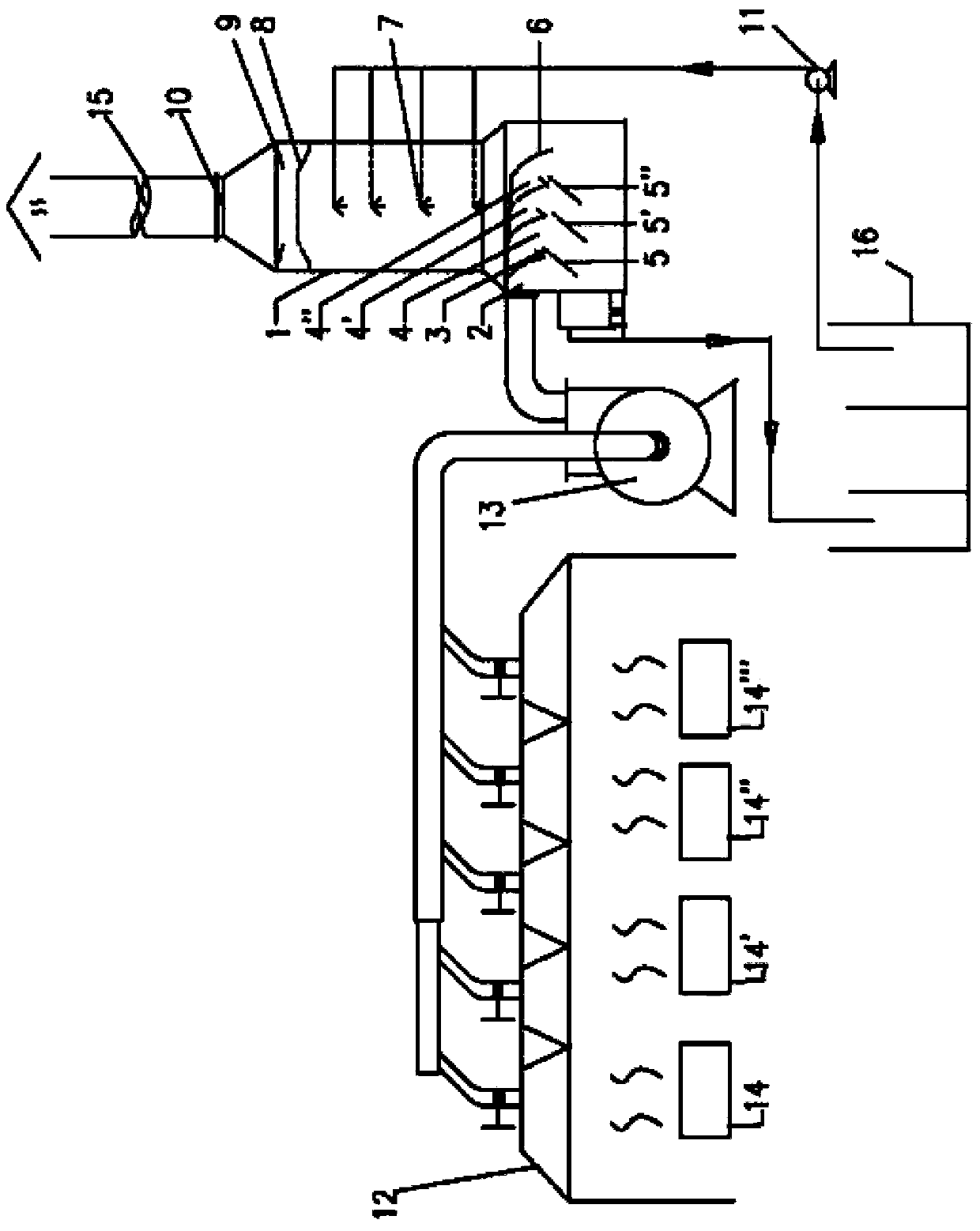

[0027] refer to figure 1 , is a structural schematic diagram of the defluorination, desulfurization and dust removal device of the present invention, which includes: a housing 1, an air inlet 2, an atomizing throat 3, a vortex chamber 4, a vortex plate 5, a liquid blocking plate 6, a spray nozzle 7, a defogging Device 8, liquid blocking plate 2 9, gas outlet 10; the air inlet is located at the lower part of the shell, and the atomizing throat is set in the air inlet chamber, and the atomizing throat is nested in the air inlet chamber, and the rear end of the atomizing throat is connected to the vortex ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com