Seed polymer and its stabilizer and method for preparing water-in-water cationic polyacrylamide copolymer dispersion using both

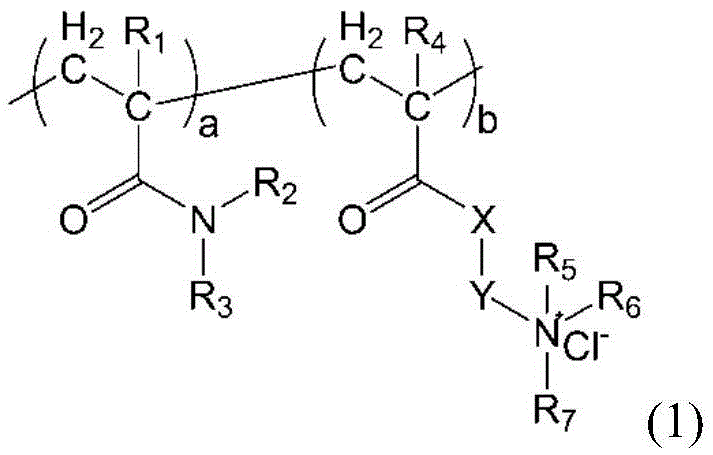

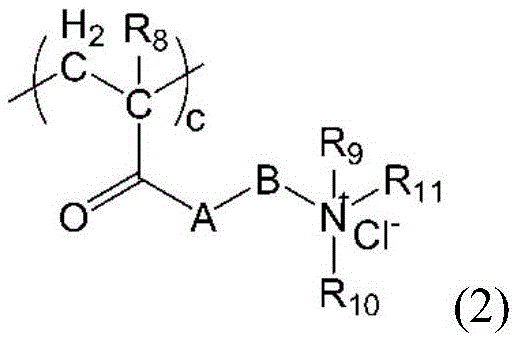

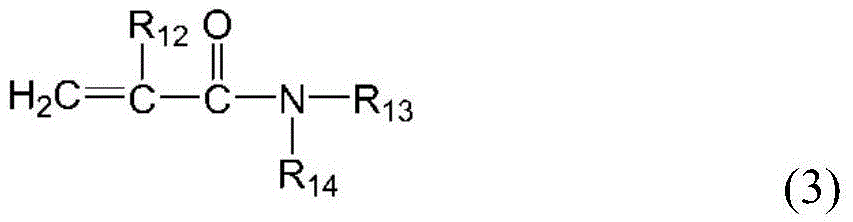

A polyacrylamide copolymer and polymer technology, which is applied in the field of preparation of cationic water-soluble polymer dispersions, can solve the problems that stabilizers cannot fully stabilize large particles, gels, poor storage performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1

[0079] Example A1 (thermal decomposition initiator): The seed dispersion liquid with monomers dissolved in accordance with the dosage in Table 3 was passed through N under the condition of mechanical stirring at 30°C. 2 except O 2 30min, N 2 Under protective conditions, 2 parts of an aqueous solution containing 3.0‰ parts of VA044 were added at one time. From the beginning of the addition, the reaction was stirred for 30 hours, and the stirring and N was stopped. 2Protection and cooling can be used to obtain a milky white P(DMAM-co-DMC) water-in-water dispersion with a cationic degree of 0.2% and an effective solid content (synthetic cationic polyacrylamide, without stabilizers and seed polymers) of 15%. The reaction process The maximum viscosity of the medium is 311.0cP, the final product viscosity is 83.1cP (25℃), and the molecular weight is 8.7×10 6 , can be stored at room temperature (25 ℃) for more than one year (see Table 4 for relevant properties).

Embodiment A2

[0080] Example A2 (redox initiator): 4.8‰ parts of sodium metabisulfite (SMBS) was added to the monomer-dissolved seed dispersion prepared according to the dosage in Table 3 and dissolved by stirring at 35°C. Keep at 35°C and mechanically stir, pass N into it 2 except O 2 30min, N 2 Under protective conditions, 2 parts of an aqueous solution containing 4.8‰ parts of ammonium persulfate (APS) were evenly added dropwise, and the dripping time was controlled to be 15 min. Since the dropwise addition, the reaction was stirred for 30 h, and the stirring and N was stopped. 2 Protection and cooling can be used to obtain a milky white P(AM-co-DMC) water-in-water dispersion with a cationic degree of 2% and an effective solid content (synthetic cationic polyacrylamide, without stabilizers and seed polymers) of 20%. The reaction process The maximum viscosity of the medium is 594.4cP, the final product viscosity is 211.0cP (25℃), and the molecular weight is 12.9×10 6 , can be stored a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com