Fluorine resin-modified polyester powder coating for aluminum profile and preparation method for fluorine resin-modified polyester powder coating

A technology of powder coating and modified polyester is applied in the field of preparation of fluororesin-modified polyester powder coatings for aluminum profiles and fluororesin-modified polyester powder coatings for aluminum profiles, which can solve the problems of high price and immature technology, etc. problem, to achieve the effect of low price and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

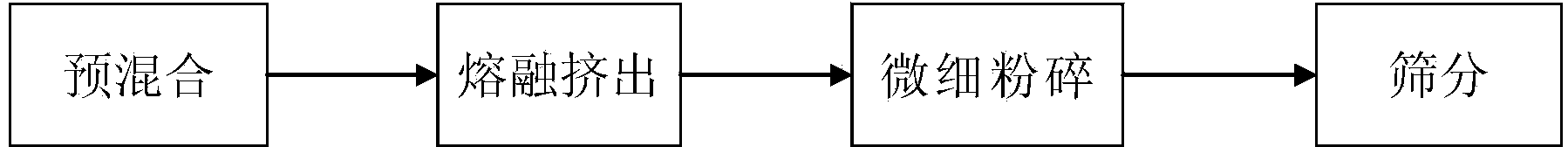

[0027] Prepare the fluororesin modified polyester powder coating for aluminum profiles according to the following steps:

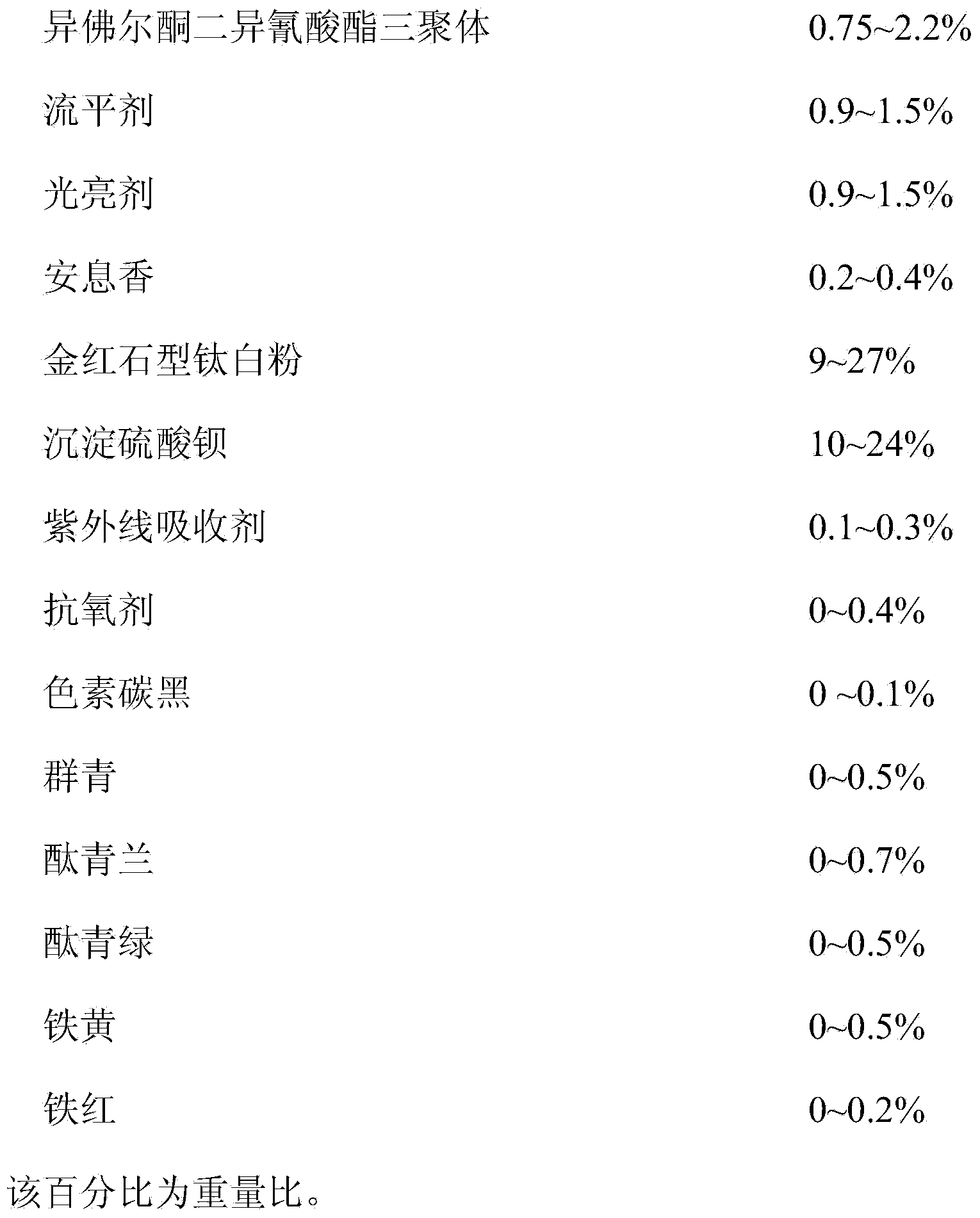

[0028] In the first step, the following raw materials are premixed according to the weight percentage,

[0029]

[0030] In the second step, the pre-mixed raw materials are melt-mixed and extruded with a twin-screw extruder, wherein the temperature of the extruder zone I is 130°C, and the temperature of the extruder zone II is 120°C;

[0031] In the third step, the extruded material is pressed into tablets, cooled and crushed, and the crushed material is finely pulverized with an ACM mill until the particle size of the powder is 10-100 microns;

[0032] In the fourth step, the finely pulverized powder coating is sieved to a particle size of 20-80 microns with a rotary sieve of 180 mesh to produce a powder coating product.

[0033] Among them, the FEVE fluorine resin is Kynar500PCFEVE resin produced by Arkema, France, and the carboxyl polyester is P4900...

Embodiment 2

[0037] Prepare the fluororesin modified polyester powder coating for aluminum profiles according to the following steps:

[0038] In the first step, the following raw materials are premixed according to the weight percentage,

[0039]

[0040] In the second step, the pre-mixed raw materials are melt-mixed and extruded with a twin-screw extruder, wherein the temperature of the extruder zone I is 125°C, and the temperature of the extruder II zone is 115°C;

[0041] In the third step, the extruded material is pressed into tablets, cooled and crushed, and the crushed material is finely pulverized with an ACM mill until the particle size of the powder is 10-100 microns;

[0042] In the fourth step, the finely pulverized powder coating is sieved to a particle size of 20-80 microns with a rotary sieve of 180 mesh to produce a powder coating product.

[0043] Among them, the FEVE fluorine resin is Kynar500PCFEVE resin produced by Arkema, France, and the carboxyl polyester is P4900...

Embodiment 3

[0047] Prepare the fluororesin modified polyester powder coating for aluminum profiles according to the following steps:

[0048] In the first step, the following raw materials are premixed according to the weight percentage,

[0049]

[0050] In the second step, the pre-mixed raw materials are melt-mixed and extruded with a twin-screw extruder, wherein the temperature of the extruder zone I is 120°C, and the temperature of the extruder II zone is 110°C;

[0051] In the third step, the extruded material is pressed into tablets, cooled and crushed, and the crushed material is finely pulverized with an ACM mill until the particle size of the powder is 10-100 microns;

[0052] In the fourth step, the finely pulverized powder coating is sieved to a particle size of 20-80 microns with a rotary sieve of 180 mesh to produce a powder coating product.

[0053] Among them, the FEVE fluororesin is Kynar500PCFEVE resin produced by ArkeMe, France, and the carboxylated polyester is P490...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com