Silicate luminescent material and preparation method thereof

A technology of luminescent materials and silicates, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of shortening the service life of field emission devices, reducing the luminous efficiency of phosphors, and need to be improved and improved, and achieves broad production and application prospects. , the effect of improved luminous performance and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of Gd by High Temperature Solid State Method 1.95 (Si 0.999 sn 0.001 ) SiO 5 :Tb 0.05

[0026] Weigh Gd 2 (CO 3 ) 3 1.9286g, SiO 2 0.2401g, SnO 2 0.0006g, Tb 2 (CO 3 ) 3 0.0497g, placed in an agate mortar and thoroughly ground to mix evenly, then the powder was transferred to a corundum crucible, in a tube furnace in pure H 2 Sintering at 1100°C for 6h in a reducing atmosphere and cooling to room temperature to obtain Gd 1.95- (Si 0.999 sn 0.001 ) SiO 5 :Tb 0.05 Silicate luminescent material.

Embodiment 2

[0028] Preparation of Y by high-temperature solid-phase method 1.92 (Si 0.997 sn 0.003 )O 5 :Tb 0.08

[0029] weigh Y 2 o 3 0.8670g, SiO 2 0.2396g, SnO 2 0.0018g, Tb 4 o 7 0.0598g, put it in an agate mortar and grind it until it is evenly mixed, then transfer the powder to a corundum crucible, and place it in a tube furnace at 95v%N 2 +5v%H 2 Sintering at 1200°C for 2 hours in a weak reducing atmosphere and cooling to room temperature to obtain Y 1.92 (Si 0.997 sn 0.003 )O 5 :Tb 0.08 Silicate luminescent material.

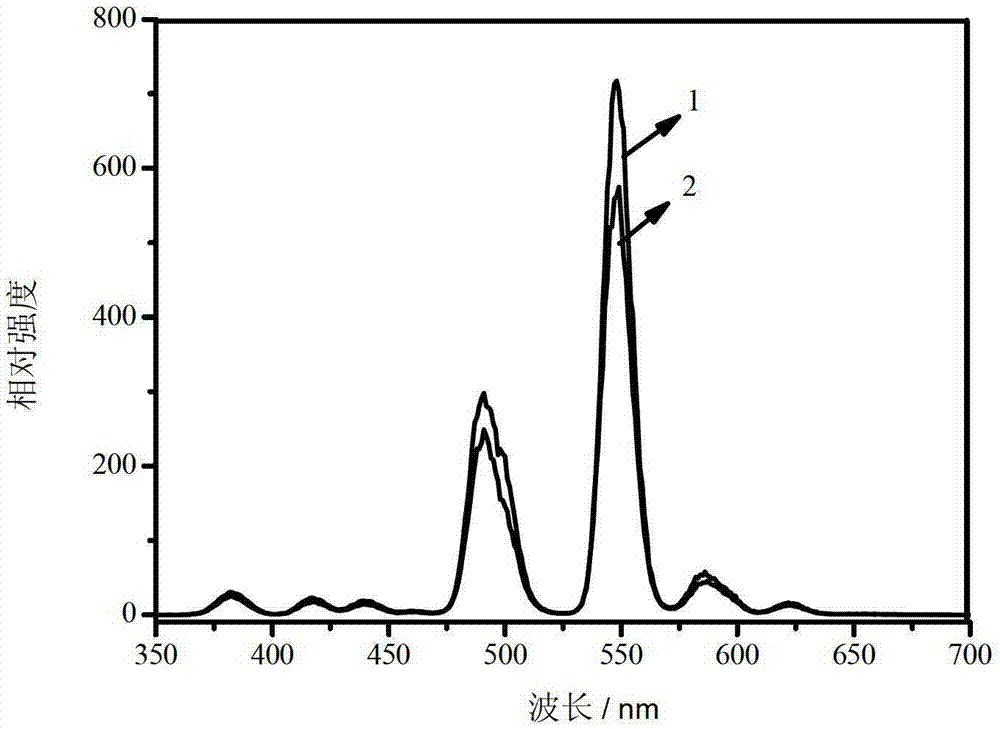

[0030] figure 1 It is a comparison chart of the luminescence spectra of the silicate luminescent material prepared in Example 2 and the comparative luminescent material under the excitation of cathode rays at an accelerating voltage of 3KV; wherein, Curve 1 is the silicate luminescent material prepared in Example 2: adding SnO 2 After Y 1.92 (Si 0.997 sn 0.003 )O 5 :Tb 0.08 The luminescent spectrum of the luminescent material; Curve 2 is a co...

Embodiment 3

[0033] Preparation of Sc by high temperature solid state method 1.90 (Si 0.999 In 0.001 )O5 :Tb 0.10

[0034] Weigh Sc 2 (CO 3 ) 3 1.0257g, SiO 2 0.2401g, In 2 o 3 0.0005g, Tb 2 (CO 3 ) 3 0.0995g, put it in an agate mortar and grind until it is evenly mixed, then transfer the powder to a corundum crucible, sinter in a tube furnace at 1000°C for 8h in a CO reducing atmosphere, and cool to room temperature to obtain Sc 1.90 (Si 0.999 In 0.001 )O 5 :Tb 0.10 Silicate luminescent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com