Asphalt additive, modified asphalt, its preparation method, application and preparation method of asphalt charcoal

An asphalt additive and modified asphalt technology, which is applied in the processing of tar asphalt/petroleum asphalt/natural asphalt, chemically processing tar asphalt/petroleum asphalt/natural asphalt, coking carbonaceous materials, etc. , complex process and other problems, to achieve the effect of low cost, simple operation and high carbon residue rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

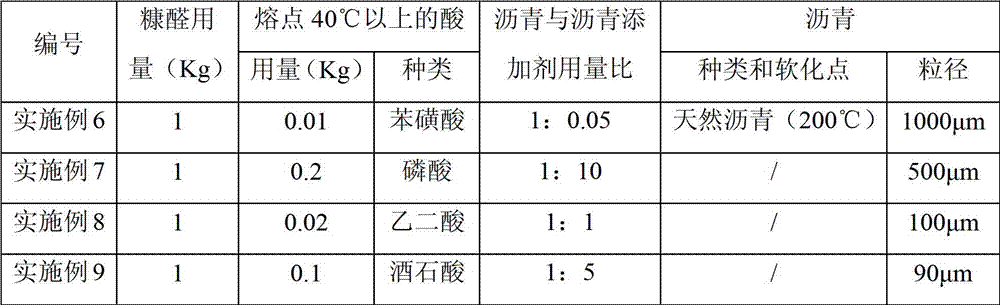

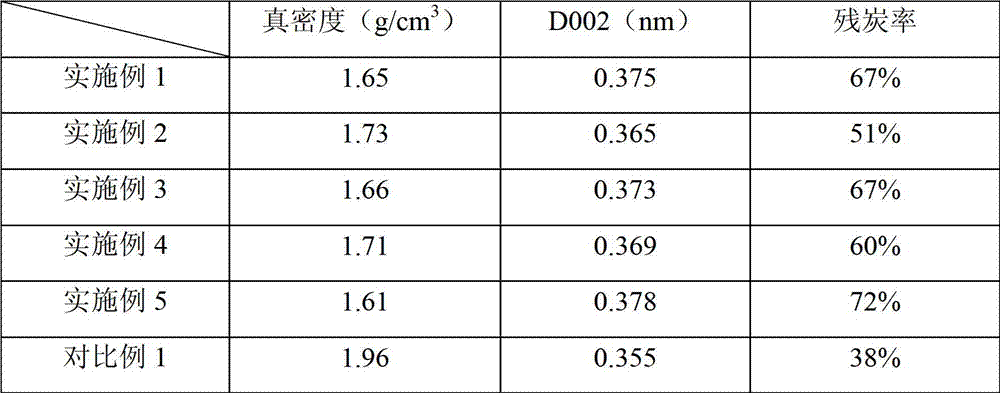

Examples

Embodiment 1

[0031] Asphalt additive: Add 0.9 kg of furfural and 0.1 kg of p-toluenesulfonic acid into the reaction kettle at room temperature, stir and blend for 1 hour to obtain the additive.

[0032] Modified asphalt: Grind 3kg of coal tar pitch (softening point 102°C) through 60 mesh (250μm), and mix with 1kg of asphalt additive at room temperature for 1 hour to obtain modified asphalt.

[0033] Asphalt carbonization: the above-mentioned modified asphalt is raised to 1000°C at 5°C / min for carbonization treatment.

Embodiment 2

[0035] Asphalt additive: Add 0.98 kg of furfural and 0.02 kg of p-toluenesulfonic acid into the reaction kettle at room temperature, stir and blend for 1 hour to obtain the additive.

[0036] Modified asphalt: Heat 5kg of coal tar pitch (softening point 97°C) to 100°C, stir and blend with 1kg of asphalt additive to obtain modified asphalt.

[0037] Asphalt carbonization: The modified asphalt is raised to 1000°C at 10°C / min for carbonization.

Embodiment 3

[0039] Asphalt additive: Add 0.9 kg of furfural and 0.1 kg of p-toluenesulfonic acid into the reaction kettle at room temperature, stir and blend for 1 hour to obtain the additive.

[0040] Modified asphalt: Grind 3kg of petroleum asphalt (softening point 287°C) through 60 mesh (250μm), mix with 1kg of asphalt additive, stir and blend at room temperature for 1 hour to obtain modified asphalt.

[0041] Asphalt carbonization: The modified asphalt is raised to 1000°C at 5°C / min for carbonization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com