Preparation process of high-strength graphite material

A technology of graphite material and preparation process, applied in the field of preparation technology of high-strength graphite material, can solve the problems of increased production cost, low bulk density and strength, and high porosity, and achieves high shrinkage, low preparation cost, and low sulfur strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

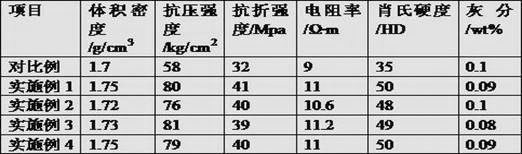

Examples

Embodiment 1

[0051] Preparation process of high strength graphite material, including the following steps:

[0052] Step 1, select the petroleum coke, put the raw petroleum coke into the drum furnace;

[0053] Step 2, the warming curve is developed to be heated to obtain a half, wherein the temperature limit of the temperature rise curve is 550 ° C;

[0054] Step three, the half-coke abrasion obtained by step two is 5 μm, then inserted into the mixer pot and add the dispersant to the mixing pot, warmed to 140 ° C, mixed 45min, and then put the molten binder in the mixed pot. Keep the temperature 140 ° C, mix 45min, to obtain a paste;

[0055] Step 4, the primary paste is processed by 2 rolling pieces to obtain a rolling sheet;

[0056] Step 5, the mill is grinded to the average particle size of 20 μm, and then the mold is formed;

[0057] Step 6, calcinate the green body, then perform graphitization, resulting in a finished high strength graphite material,

[0058] Relief focus, high temperatu...

Embodiment 2

[0061] Preparation process of high strength graphite material, including the following steps:

[0062] Step 1, select the petroleum coke, put the raw petroleum coke into the drum furnace;

[0063] Step 2, the warming curve is developed to be heated to obtain a half, wherein the temperature limit of the temperature rise curve is 550 ° C;

[0064] Step three, the half-coke grinding powder obtained by step two is 6 μm, then inserted into the mixed pot and add the dispersant to the mixing pot, warmed to 145 ° C, mixed 45min, and then put the molten binder in the mixed pot. Keep the temperature of 150 ° C, mix 45min, to obtain a paste;

[0065] Step 4, the primary paste is processed by 2 rolling pieces to obtain a rolling sheet;

[0066] Step 5, the mill is grinded to the average particle size of 22 μm, and then the mold is obtained;

[0067] Step 6, calcinate the green body, then perform graphitization, resulting in a finished high strength graphite material,

[0068] Raw stone oil coke...

Embodiment 3

[0071] Preparation process of high strength graphite material, including the following steps:

[0072] Step 1, select the petroleum coke, put the raw petroleum coke into the drum furnace;

[0073] Step 2, the warming curve is developed to be heated to obtain a half, wherein the temperature limit of the temperature rise curve is 550 ° C;

[0074] Step three, the half-coke grinding powder obtained by step two is 5 μm, then inserted into the mixer pot and add the dispersant to the blended pot, warmed to 150 ° C, mixed 45min, and then put the molten binder into the mixed pot. Keep the temperature 140 ° C, mix 45min, to obtain a paste;

[0075] Step 4, the primary paste is processed by 2 rolling pieces to obtain a rolling sheet;

[0076] Step 5, the mill is grinded to the average particle size of 21 μm, and then the mold is formed;

[0077] Step 6, calcinate the green body, then perform graphitization, resulting in a finished high strength graphite material,

[0078] Raw petroleum coke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com