Hybrid Compound Pulley Continuously Variable Automatic Transmission

An automatic transmission, hybrid technology, applied in the direction of belts/chains/gears, transmissions, components with teeth, etc., can solve the problem that the control model is not mastered in China, there are few public materials, and the design, development, and manufacturing are complicated. and other problems, to achieve the effect of simple and reasonable control mode, reduction of research and development costs, and easy manufacturing and realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

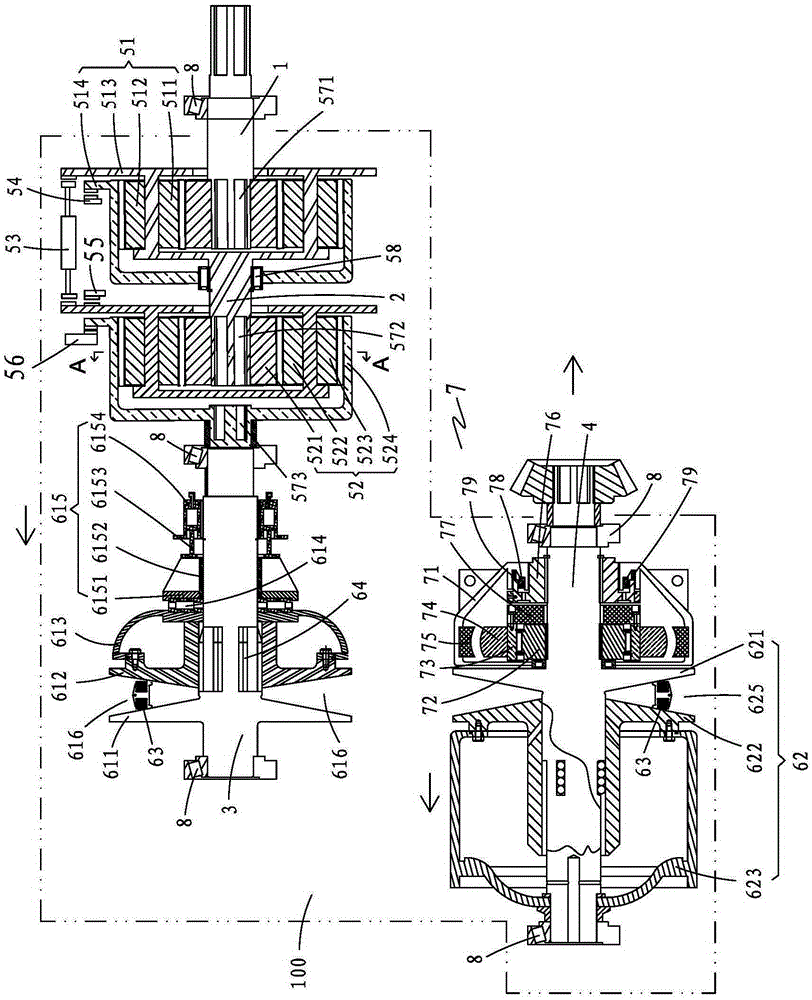

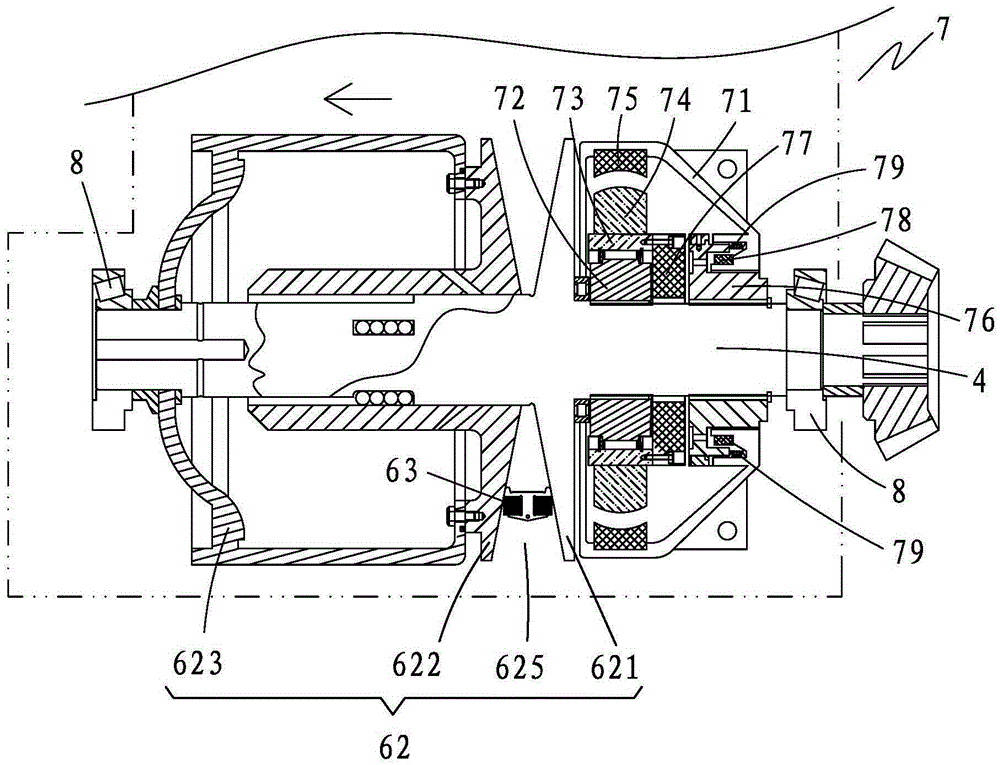

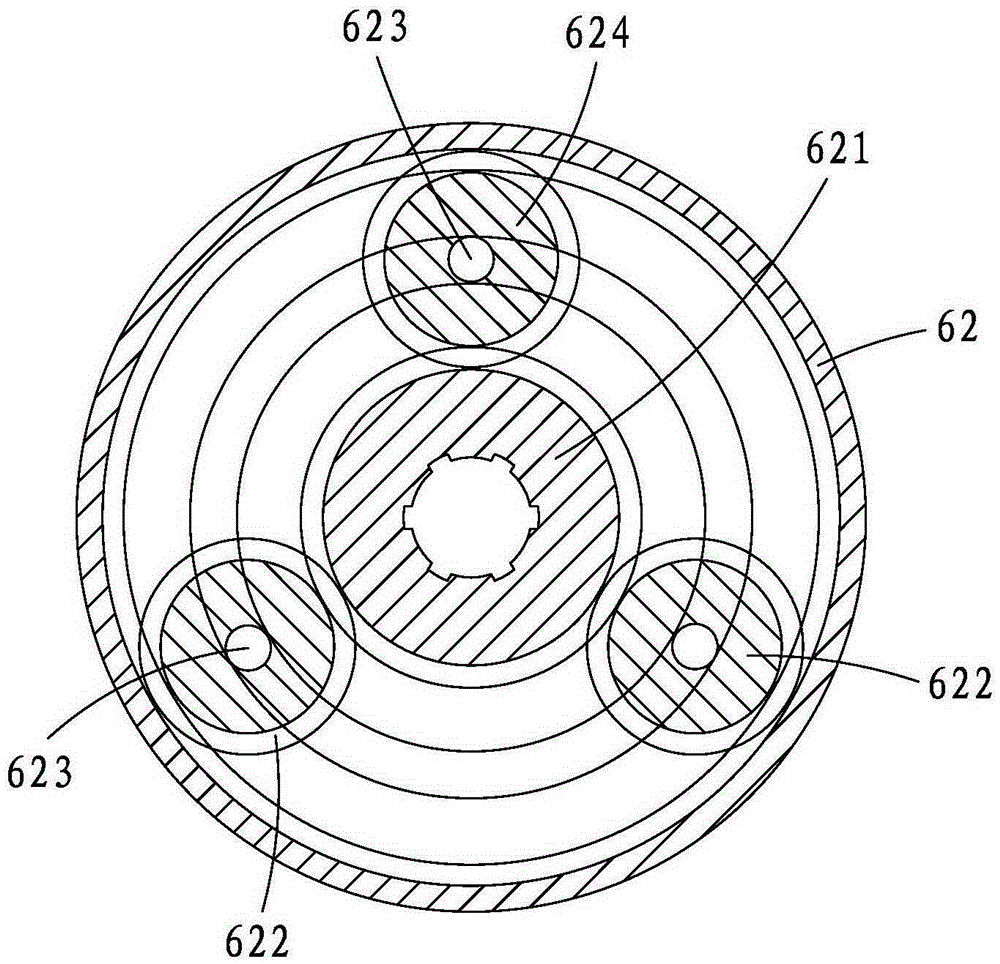

[0016] Such as figure 1 with figure 2 As shown, the hybrid compound pulley type continuously variable automatic transmission 100 of the present invention includes a transmission housing (not shown), a first power input shaft 1, a second power input shaft 2, a third power input shaft 3, The power output shaft 4, the power input driving mechanism 5, the front and rear pulley power transmission mechanism 6 and the hybrid one-way clutch mechanism 7; the first power input shaft 1, the second power input shaft 2, and the third power input shaft 3 Arranged coaxially in sequence, the power output shaft 4 and the third power input shaft 3 are arranged parallel and side by side; the power input driving mechanism 5 is sequentially connected to the first power input shaft 1, the second power input shaft 2 and the third power input shaft 3. The front and rear pulley power transmission mechanisms 6 are connected to the third power input shaft 3 and the power output shaft 4 respectively, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com