Negative electrode plate material of tubular lead-carbon battery

A lead-carbon battery and negative plate technology, which is applied in the direction of lead-acid battery electrodes, battery electrodes, lead-acid batteries, etc., can solve the problem of poor high-current charging acceptance capacity of the negative plate and cycle life that cannot match the cycle life of the positive plate of the tubular battery, etc. problems, to achieve the effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

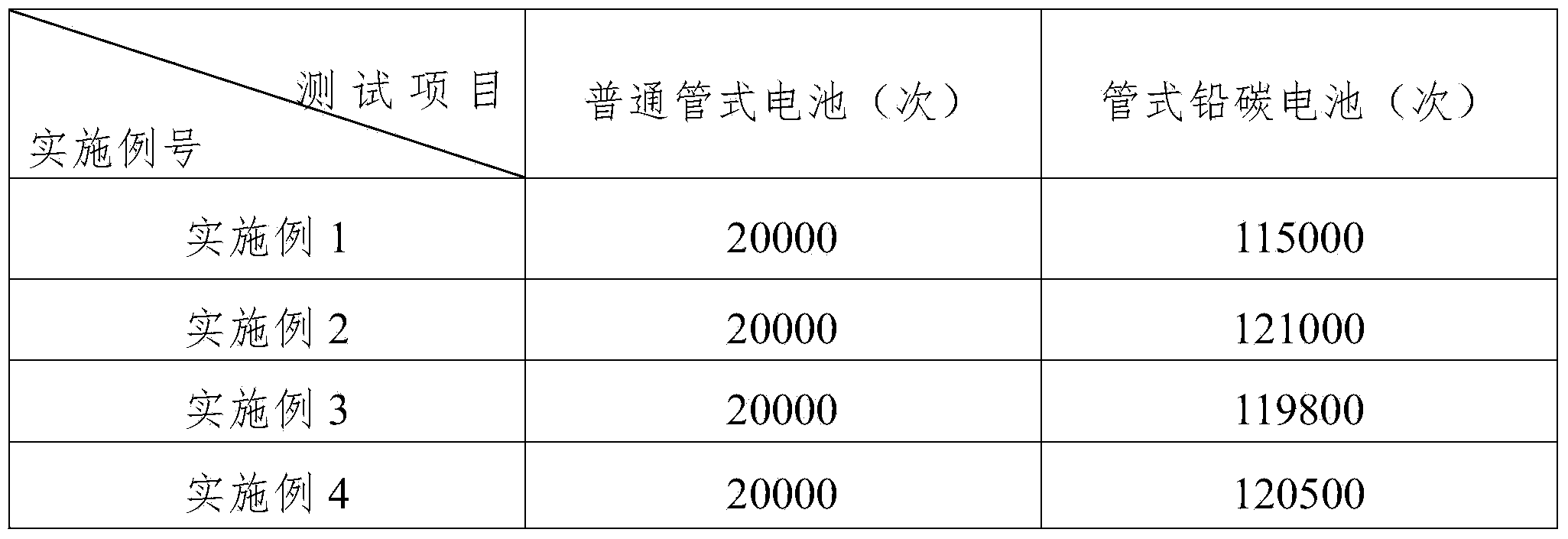

Examples

Embodiment 1

[0007] A positive plate of a tubular lead-carbon battery, weighed in parts by weight:

[0008] Lead powder: 100; nano conductive ceramic titanium dioxide: 0.2; conductive carbon fiber: 0.4; red lead: 5

[0009] (1) Pour the weighed lead powder, nano-conductive ceramic titanium dioxide, red lead, and conductive carbon fiber into the container, and stir for 10-15 minutes to mix the components evenly;

[0010] (2) Pour it into the positive electrode grid with a row of pipes, and seal the bottom sleeve

[0011] (3) Soak in 1.4g / ml dilute sulfuric acid solution for 2 hours.

[0012] (4) Put it into a curing chamber for curing and drying to make a positive plate of a tubular lead-carbon battery.

[0013] A tubular lead-carbon battery negative plate, weighed in parts by weight:

[0014] Lead powder: 100; sulfuric acid: 9.5; barium sulfate: 0.8; nano capacitor carbon: 0.5; nano conductive carbon fiber: 0.5; graphene: 0.5; humic acid: 0.1; polyester fiber: 0.25; water: 14; lignin: 0...

Embodiment 2

[0029] A positive plate of a tubular lead-carbon battery, weighed in parts by weight:

[0030] Lead powder: 100; Nano conductive ceramic titanium dioxide: 0.5; Conductive carbon fiber: 0.1; Red lead: 7.

[0031] Concrete preparation method is with embodiment 1

[0032] A tubular lead-carbon battery negative plate, weighed in parts by weight:

[0033] Lead powder: 100; sulfuric acid: 10; barium sulfate: 1.0; nano capacitor carbon: 0.5; nano conductive carbon fiber: 0.5; expanded graphite: 1.0; humic acid: 0.3; polyester fiber: 0.25; water: 14; lignin: 0.1 ; Barium stearate: 0.1;

[0034] The negative plate of the tubular lead-carbon battery was prepared according to the production method of the negative plate of the ordinary valve-regulated battery. Control the apparent density of the lead paste at 3.8-4.7g / ml.

[0035] The lead-carbon battery tubular positive plate and negative plate are assembled into a battery, the battery separator uses AGM separator, and a certain amou...

Embodiment 3

[0037] A tube-type positive plate for a lead-carbon battery, which is weighed by weight:

[0038] Lead powder: 100; conductive carbon fiber: 0.5; red lead: 9.

[0039] Concrete preparation method is with embodiment 1

[0040] A lead-carbon battery negative plate, weighed by weight:

[0041] Lead powder: 100; sulfuric acid: 10; barium sulfate: 1.0; nano capacitor carbon: 0.2; nano conductive carbon fiber: 1.0; expanded graphite: 0.5; humic acid: 0.3; polyester fiber: 0.25: water, 14: lignin, 0.1 : barium stearate: 0.1;

[0042] The negative plate of the tubular lead-carbon battery was prepared according to the production method of the negative plate of the ordinary valve-regulated battery. Control the apparent density of the lead paste at 3.6-4.7g / ml.

[0043] The lead-carbon battery tubular positive plate and negative plate are assembled into a battery, the battery separator uses AGM separator, and a certain amount of dilute sulfuric acid electrolyte is added. A tubular l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com