Carbon material in-situ deposited nanometer lead crystal grain/lead oxide composite material and preparation method thereof

An in-situ deposition and composite material technology, applied in the field of nanomaterials, can solve the problems of increasing the self-discharge reaction of lead-carbon batteries, increasing the cost of lead negative electrode recycling, unfavorable industrial production, etc., to achieve large-scale production, electrochemical Excellent performance and the effect of suppressing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

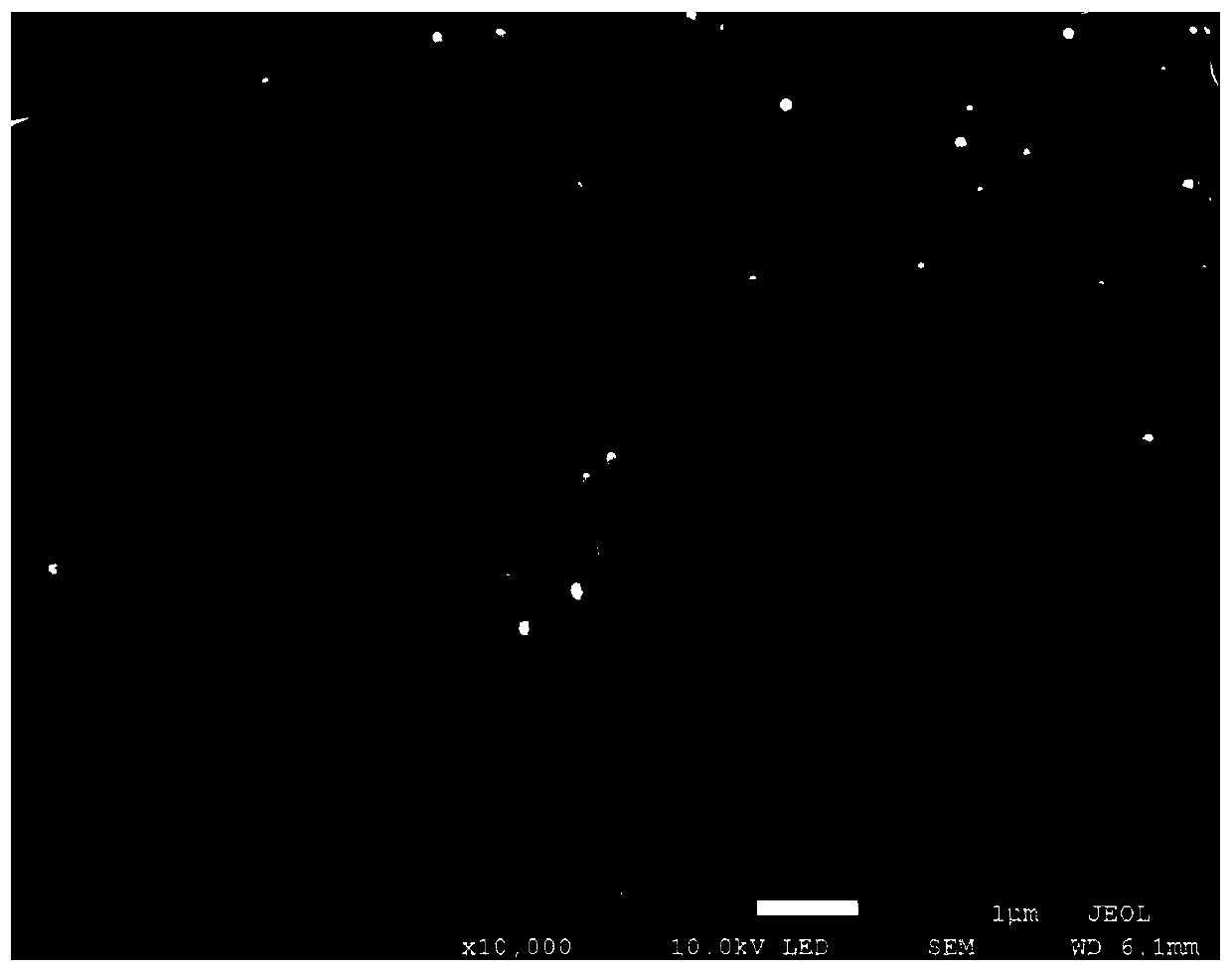

Image

Examples

Embodiment 1

[0029] A carbon material in-situ deposited nano-lead / lead oxide grain composite material and its mass percentage are:

[0030] Carbon material 80%

[0031] Nano lead grains 15%

[0032] Lead Oxide 5%

[0033] Wherein: the carbon material is graphene nanosheets.

[0034] A preparation method for in-situ deposition of carbon material nano-lead crystal grains / lead oxide composite material, the specific steps are as follows:

[0035] (1) Dissolve lead nitrate in deionized water according to the ratio of the mass (g) of lead nitrate: the volume (ml) of deionized water is 0.1:500, and mix solution A after fully stirring.

[0036] (2) According to the mass (g) of the carbon material: the ratio of the volume of the mixed solution A (ml) is 1:500, the carbon material is uniformly dispersed in the mixed solution A, and mixed and stirred at room temperature for 10 minutes to obtain carbon Mixture B of material and soluble lead salt.

[0037] Wherein: the carbon material is graphene ...

Embodiment 2

[0044] A carbon material in-situ deposited nano-lead crystal grains / lead oxide composite material and its mass percentage are:

[0045] Carbon material 70%

[0046] Nano lead grains 24%

[0047] Lead Oxide 6%

[0048] Wherein: the carbon material is carbon nanotube.

[0049] A preparation method for in-situ deposition of carbon material nano-lead grains / lead oxide composite material, same as Example 1, wherein:

[0050] In step (1), the mixed solution A is configured according to the ratio of the mass (g) of lead nitrate: the volume (mL) of deionized water is 0.2:500.

[0051] In step (2), the mixed solution B is prepared according to the ratio of the mass (g) of the carbon material: the volume (mL) of the mixed solution A is 1:500, and stirred for 15 minutes. Wherein: the carbon material is carbon nanotube.

[0052] In step (3), the mixed solution C is prepared according to the volume ratio of the alkali solution: the mixed solution B is 1:50, and stirred for 15 minutes....

Embodiment 3

[0056] A carbon material in-situ deposited nano-lead crystal grains / lead oxide composite material and its mass percentage are:

[0057] Carbon material 60%

[0058] Nano lead grains 33%

[0059] Lead Oxide 7%

[0060] Wherein: the carbon material is activated carbon.

[0061] A preparation method for in-situ deposition of carbon material nano-lead grains / lead oxide composite material, same as Example 1, wherein:

[0062] In step (1), the mixed solution A is configured according to the ratio of the mass (g) of lead nitrate: the volume (mL) of deionized water is 0.3:500.

[0063] In step (2), the mixed solution B is prepared according to the mass (g) of the carbon material: the volume (mL) of the mixed solution A is 1:500, and stirred for 18 minutes. Wherein: the carbon material is activated carbon.

[0064] In step (3), the mixed solution C is prepared according to the volume ratio of the alkali solution: the mixed solution B is 1:50, and stirred for 18 minutes. Wherein: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com