Si-based-alloy anode material

一种合金负极、合金的技术,应用在负电极、电池电极、活性物质电极等方向,能够解决导电性差、蓄电设备寿命短、不能获得Si导电性等问题,达到循环寿命优异、防止崩塌的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0074] Hereinafter, the present invention will be specifically described through examples.

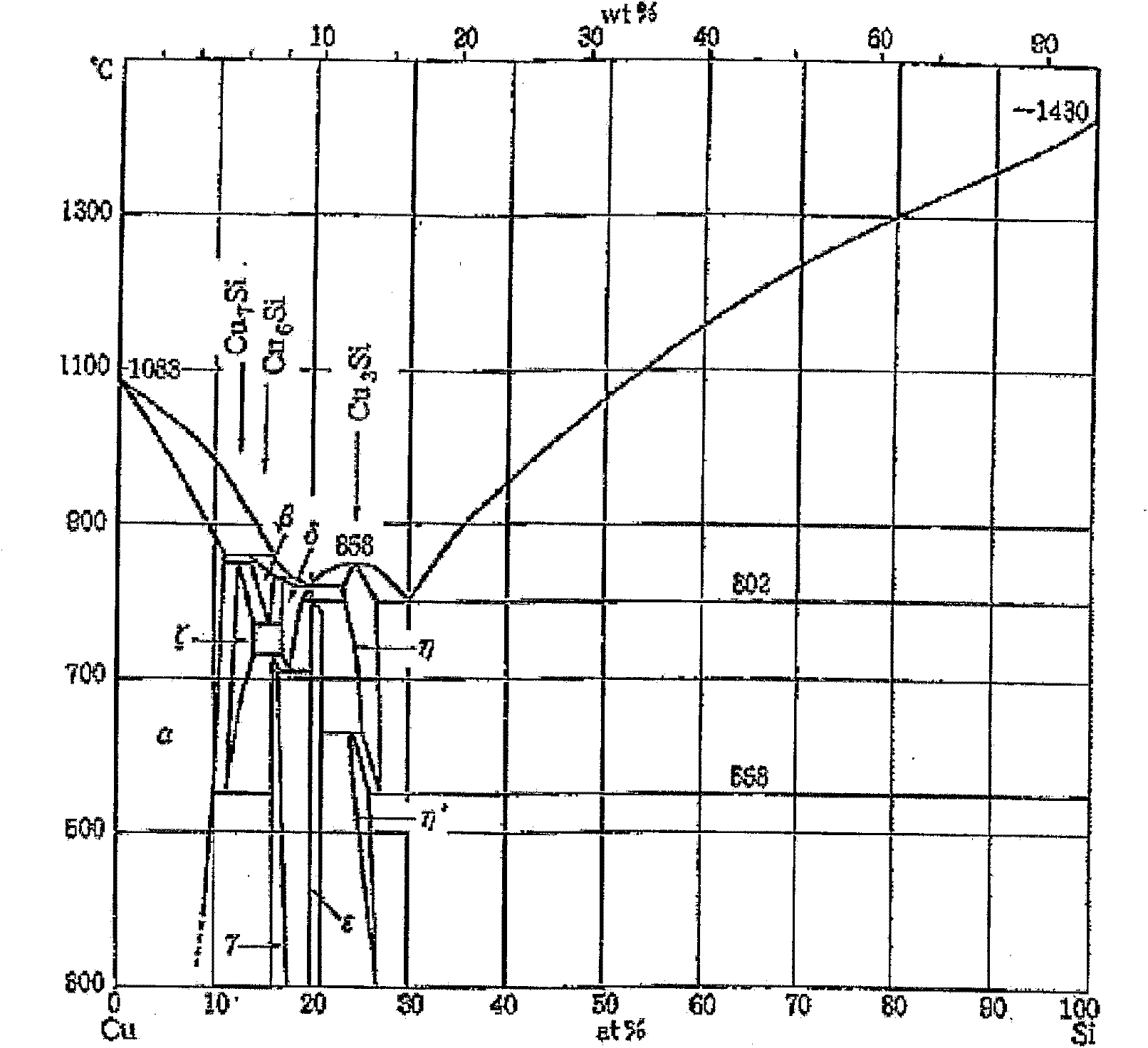

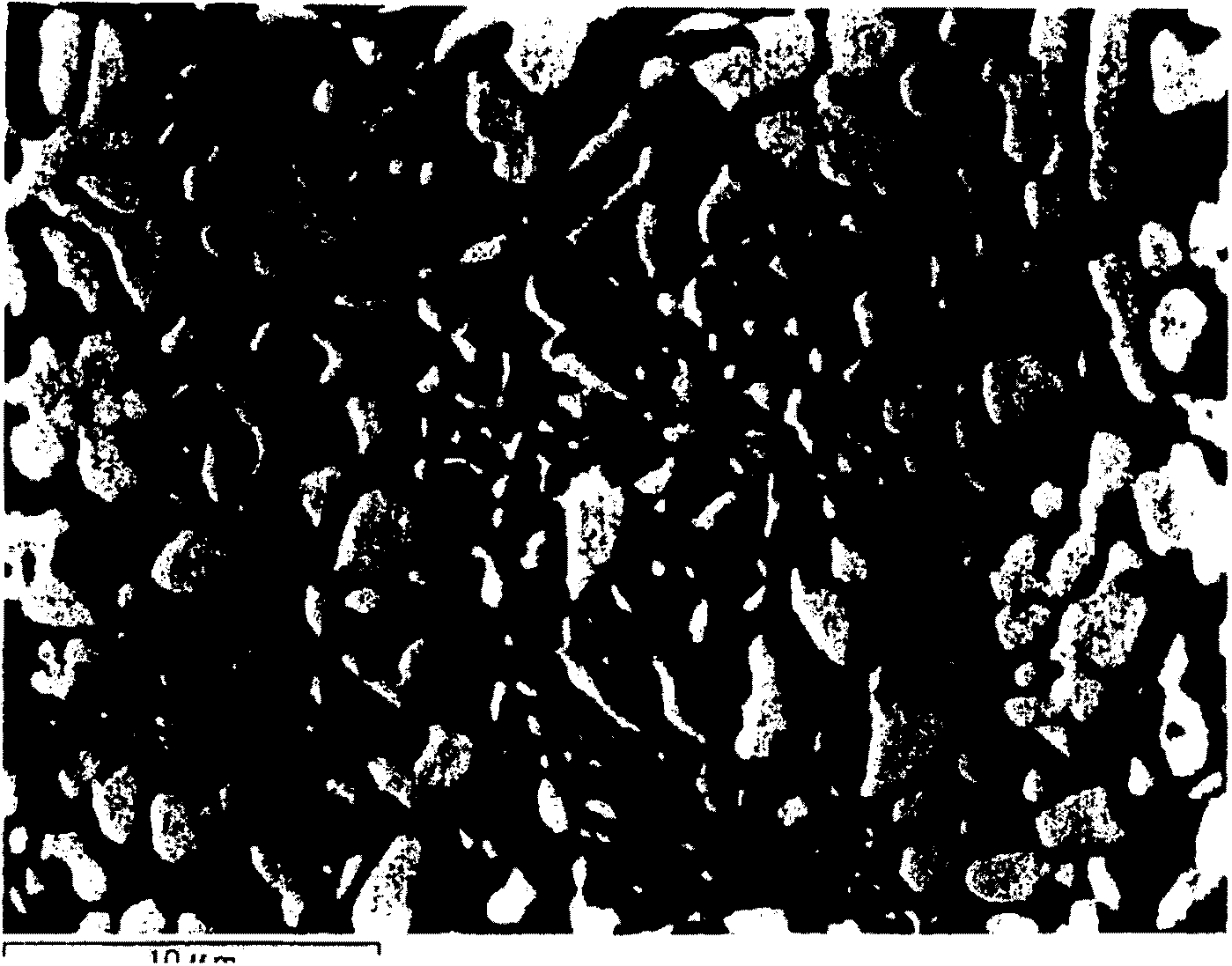

[0075] Negative electrode material powders having the compositions shown in Table 1 were produced by the single roll method, gas atomization method, or disk atomization method described below. In the liquid quenching method, which is a single-roll method, the raw material of a predetermined composition is put into a quartz tube with fine holes at the bottom, high-frequency melted in an Ar atmosphere to form a melt, and the melt is placed on the surface of a rotating copper roll. After being released from the furnace, a quenched belt forming an amorphous Si phase was produced by the quenching effect by the copper roll. Then, the produced quenched belt was sealed in an Ar atmosphere together with zirconia balls in a can container made of zirconia, and powdered by mechanical ball milling.

[0076] Regarding the gas atomization method, a raw material of a predetermined composition is put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com