A f-theta optical mold processing method

A mold processing and optical technology, applied in the field of ultra-precision machining, can solve problems such as the influence of stable machining results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

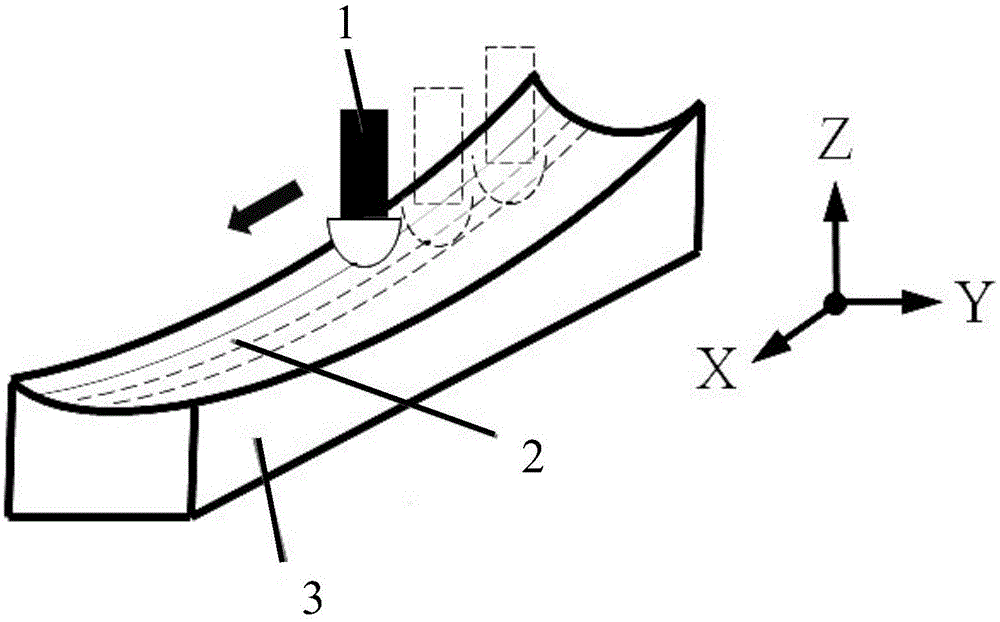

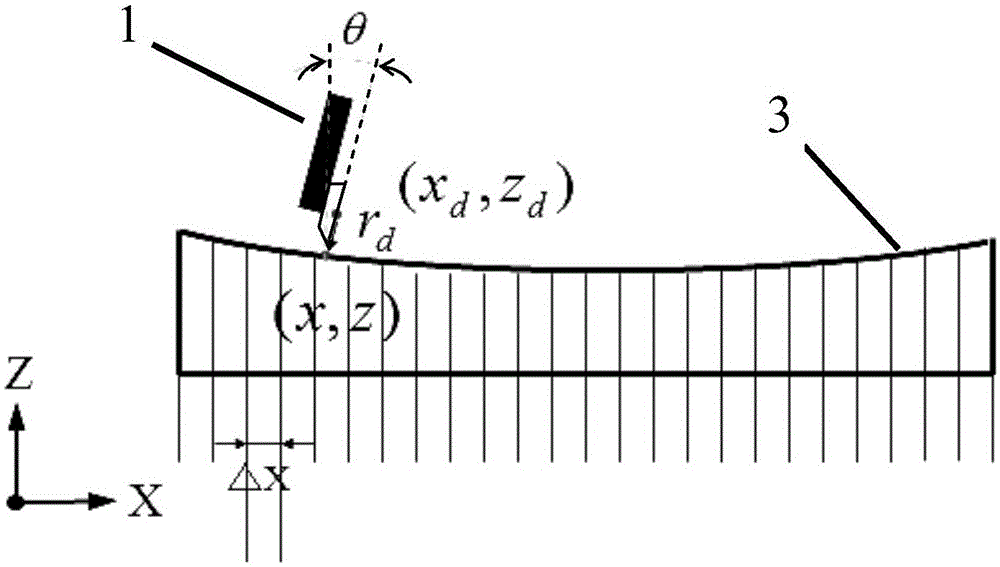

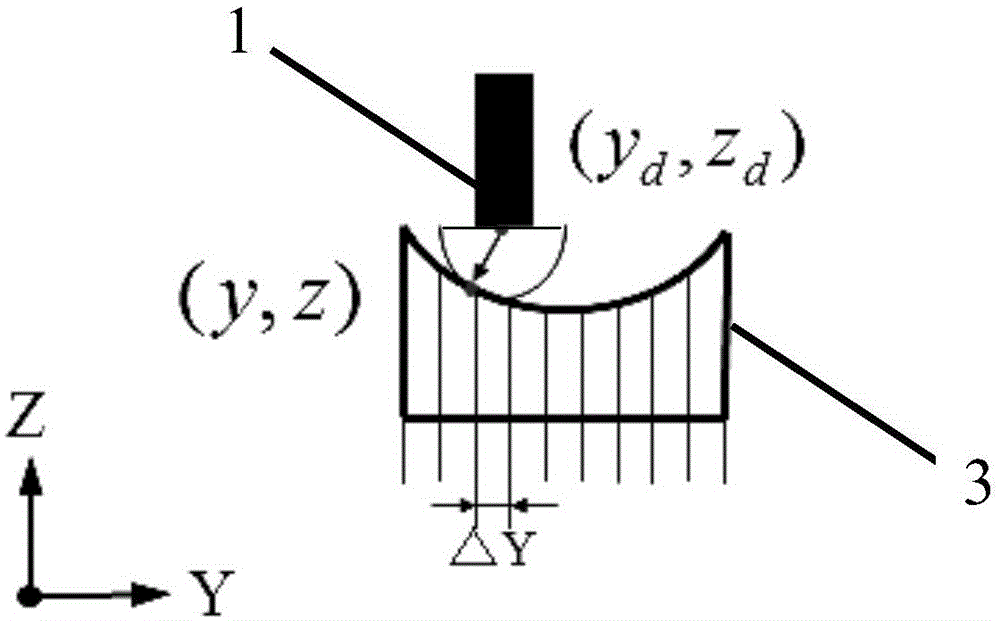

[0049] like figure 1 As shown, in the f-θ optical mold processing method of the present invention, the arc envelope cutting method is adopted, and the cutting tool 1 processes the f-θ optical mold 3 along the cutting track 2 .

[0050] The tool center point trajectory (x d ,y d ,z d ) and workpiece surface point coordinates (x s ,y s ,z s ) fits equation (1):

[0051] x d = x s + r d sin θ y d = y s ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com