Filler wire argon tungsten-arc welding process for molybdenum-copper alloy and nickel-base superalloy

A nickel-based superalloy and argon tungsten arc welding technology, which is applied in arc welding equipment, metal processing equipment, welding equipment, etc., can solve problems such as cracking, microcracks, large differences in thermal conductivity and linear expansion coefficient, etc. , to achieve the effect of reducing harmful effects, reducing oxygen content, and avoiding coarsening

Inactive Publication Date: 2014-06-18

SHANDONG UNIV

View PDF6 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

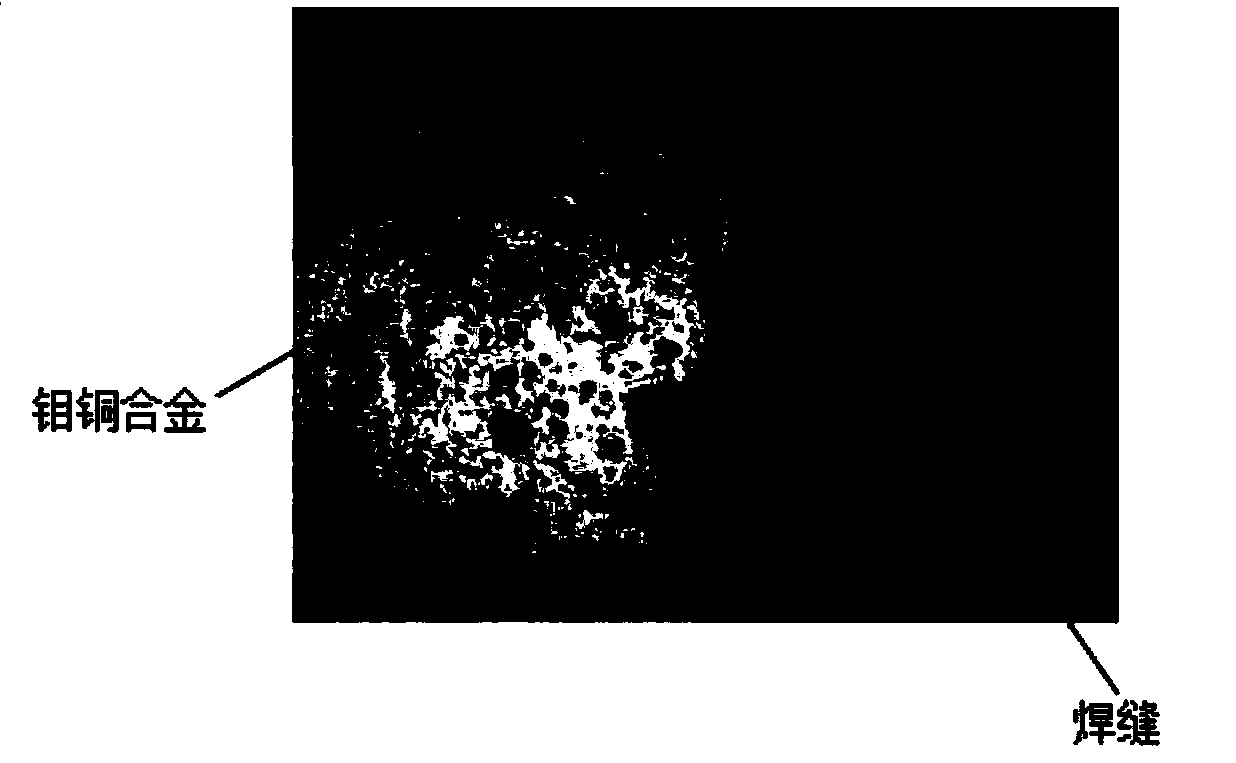

In addition, the thermal conductivity and linear expansion coefficient of molybdenum-copper alloy and nickel-based superalloy are quite different, and welding stress is likely to occur in the solder joint area during welding, forming microcracks and even further expanding under the action of stress to cause cracking

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a filler wire argon tungsten-arc welding process for a molybdenum-copper alloy and a nickel-base superalloy. The filler wire argon tungsten-arc welding process comprises the steps of surface processing, fixed point welding, preheating before welding, welding, weld pass cleaning and slow cooling after welding. A Ni-Fe-Cr system alloy welding wire is adopted in the filler wire argon tungsten-arc welding process, and the content of a Ni element in the welding wire is controlled, so that the density of a heat affected zone organization on one side, close to the molybdenum-copper alloy, of a connector can be effectively improved. The filler wire argon tungsten-arc welding process for the molybdenum-copper alloy and the nickel-base superalloy has the advantages of being convenient to operate, stable in connector performance, high in welding efficiency, convenient to popularize and apply and the like. The filler wire argon tungsten-arc welding process is particularly suitable for welding the molybdenum-copper alloy and the nickel-base superalloy, and also can be used for welding the molybdenum-copper alloy and other high-temperature alloys.

Description

technical field The invention relates to a fusion welding method between dissimilar materials, in particular to a welding of molybdenum-copper alloy and nickel-based superalloy, which belongs to the field of welding technology. Background technique Molybdenum-copper material is an alloy composed of two immiscible metal phases, molybdenum and copper. This material has the characteristics of both constituent metals, and can learn from each other to obtain good comprehensive performance. Molybdenum is an element with relatively good electrical and thermal conductivity in addition to high-conductivity metals such as gold, silver, and copper. Therefore, molybdenum-copper materials with high electrical and thermal conductivity metal copper are further added to have high electrical and thermal conductivity. Copper has a high thermal expansion coefficient, while molybdenum has a very low thermal expansion coefficient. Therefore, it can be made into a lower thermal expansion coeffi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K9/167B23K9/235B23K9/23B23K35/30

CPCB23K9/167B23K9/23B23K9/235B23K35/3033B23K2103/16

Inventor 王娟李亚江

Owner SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com