Multipoint floating supporting device

A floating support, multi-point technology, applied in the direction of movable track, transportation and packaging, conveyor, etc., can solve the problem that the support system and the curved track cannot be reliably contacted, and achieve compact structure, increased contact surface, and large bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

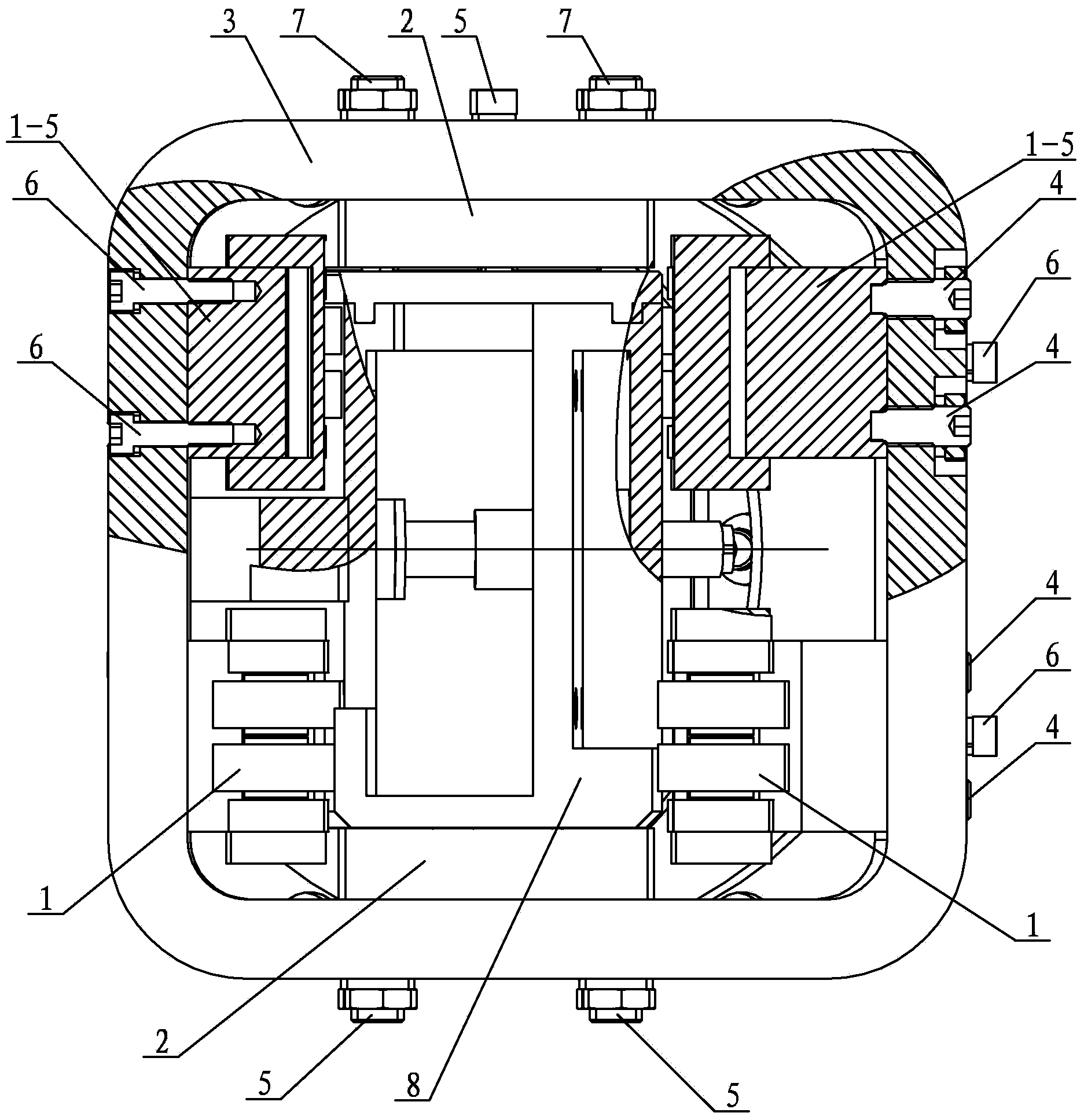

[0019] Specific implementation mode one: combine Figure 1 to Figure 8 Describe this embodiment, this embodiment includes support frame 3, two roller assemblies 2, four floating roller sets 1, four floating roller sets adjusting bolts 4, four roller assembly fixing bolts 5, six floating roller sets Fixing bolts 6 and eight roller assembly adjusting bolts 7,

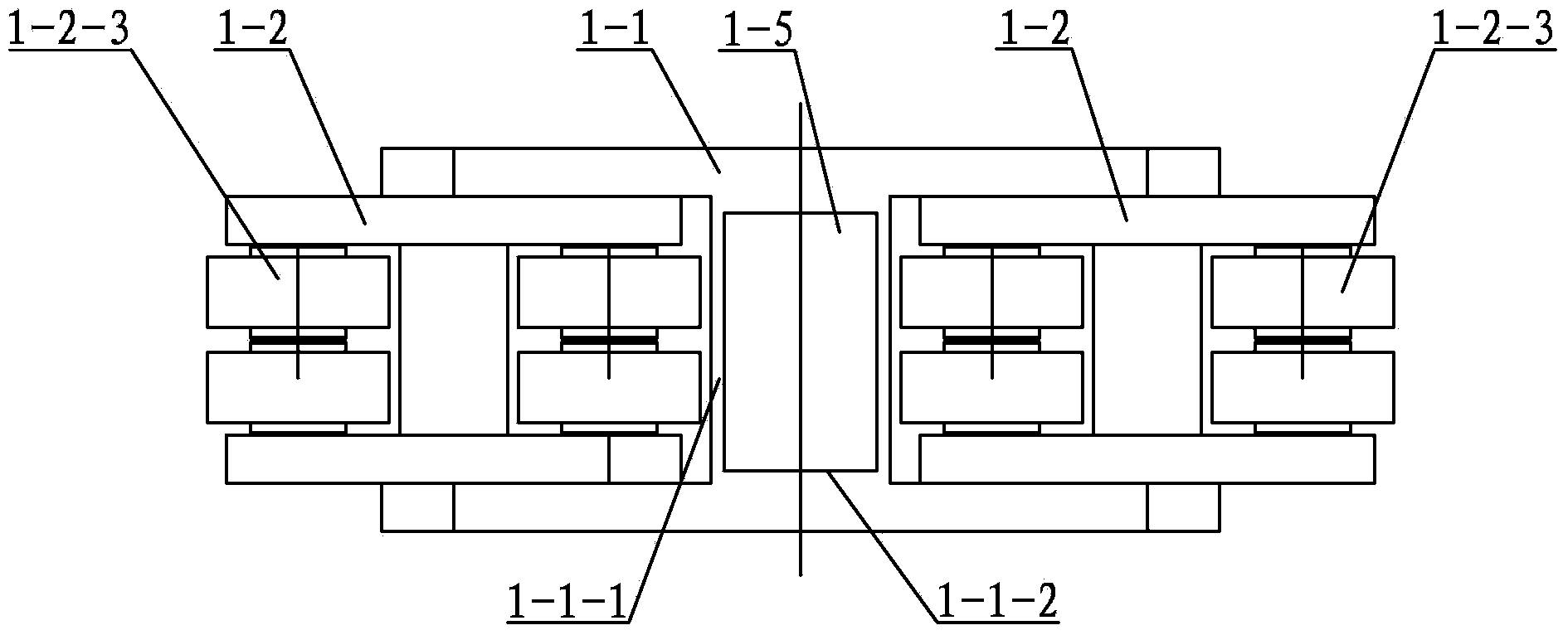

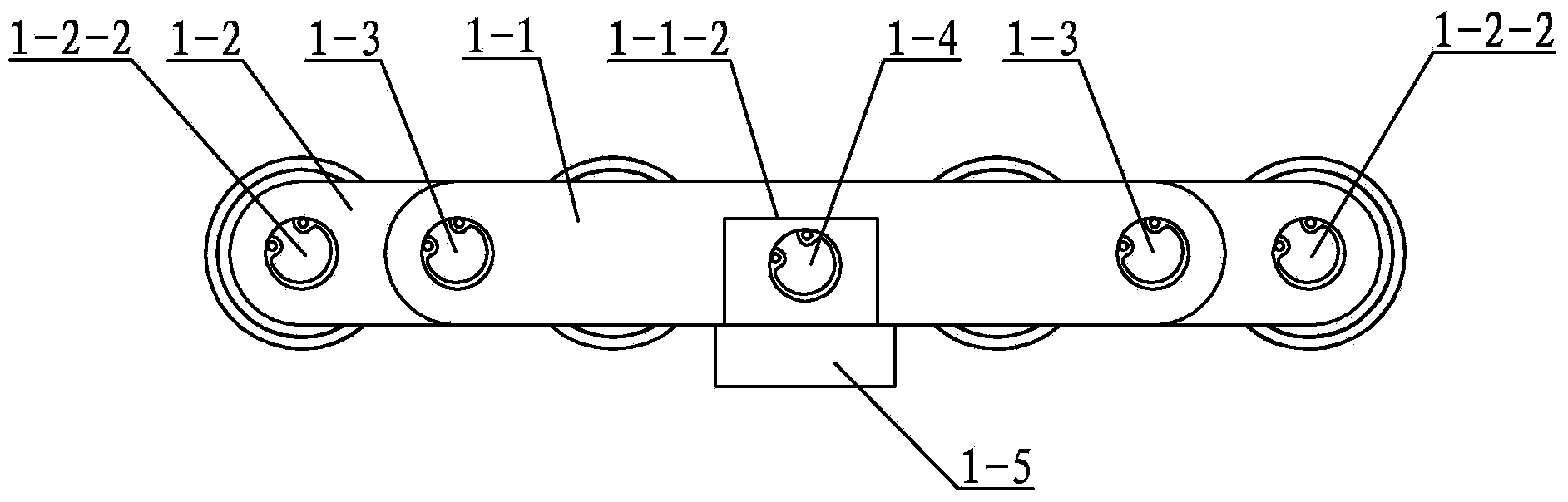

[0020] Floating roller group 1 is composed of main I-shaped frame 1-1, fixed seat shaft 1-4, fixed seat 1-5, two roller assemblies 1-2 and two roller assembly pin shafts 1-3, each roller assembly 1 -2 consists of a roller I-shaped frame 1-2-1, two roller support shafts 1-2-2 and four needle rollers 1-2-3, and the two roller support shafts 1-2-2 are symmetrically arranged on the rollers The roller I-frame vertical rib 1-2-4 two ends on the I-frame 1-2-1, and the two ends of each roller support shaft 1-2-2 are respectively connected with the roller I-frame 1-2-1 The upper and lower horizontal plates are hinged, and two ne...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination figure 2 and image 3 Describe this embodiment, in this embodiment, a powder metallurgy bearing is installed between the needle roller 1-2-3 and the roller support shaft 1-2-2, and the powder metallurgy bearing can reduce the distance between the needle roller 1-2-3 and the Frictional resistance between roller support shafts 1-2-2. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination image 3 and Figure 4 Describe this embodiment. In this embodiment, a powder metallurgy bearing is installed between the roller I-frame 1-2-1 and the pin shaft 1-3 of the roller assembly. The powder metallurgy bearing can reduce the number of roller I-frames 1-2-1 and Frictional resistance between pins 1-3 of the roller assembly. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

| Radian | aaaaa | aaaaa |

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com