Addition silicone rubber compound for protecting diode chip

A silicone rubber and composite technology, which is applied in the field of addition-type silicone rubber composites for diode chip protection, can solve the problems of high reverse current and low reverse current, and achieve the effect of low reverse current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

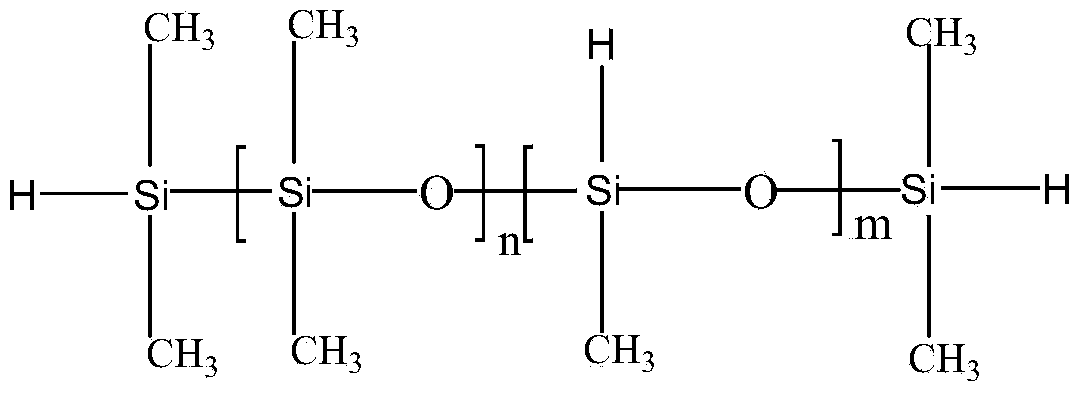

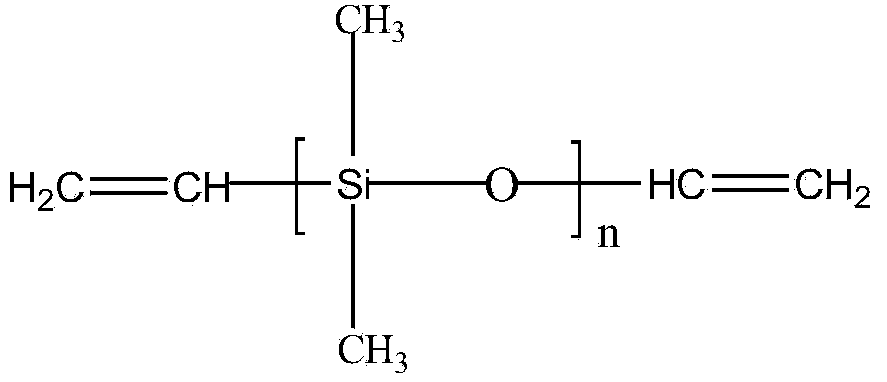

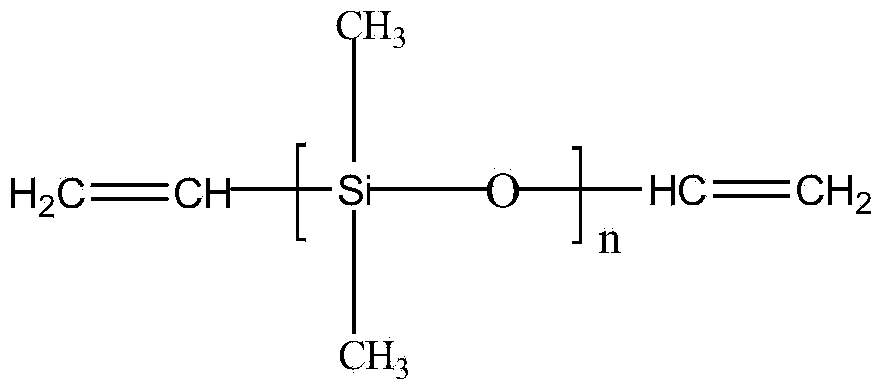

Method used

Image

Examples

Embodiment 1

[0054] Select 100 parts of vinyl silicone oil with a viscosity of 5000mPa·s, 50 parts of silane-treated silicon dioxide, 1.5 parts of titanium dioxide, 12 parts of H-containing silicone oil with a H content of 0.6%, 20 parts of vinyl MQ resin, and bond Force accelerator 1.0 parts, 1,3-divinyl-1,1,3,3-tetramethyldisiloxane platinum complex 10ppm, inhibitor 1-ethynyl cyclohexanol 0.4 parts, triphenyl Phosphine 0.03 parts.

Embodiment 2

[0056] Choose 100 parts of vinyl silicone oil with a viscosity of 1000mPa s, 50 parts of silane-treated silicon dioxide, 1.5 parts of titanium dioxide, 12 parts of H-containing silicone oil with a H content of 0.6%, 20 parts of vinyl MQ resin, and bond Force accelerator 1.0 parts, 1,3-divinyl-1,1,3,3-tetramethyldisiloxane platinum complex 50ppm, inhibitor 1-ethynyl cyclohexanol 0.4 parts, triphenyl Phosphine 0.03 parts.

Embodiment 3

[0058] Select 100 parts of vinyl silicone oil with a viscosity of 5000mPa·s, 100 parts of silane-treated silicon dioxide, 1.5 parts of titanium dioxide, 12 parts of H-containing silicone oil with a H content of 0.6%, 20 parts of vinyl MQ resin, and bond Force accelerator 1.0 parts, 1,3-divinyl-1,1,3,3-tetramethyldisiloxane platinum complex 10ppm, inhibitor 1-ethynyl cyclohexanol 0.4 parts, triphenyl Phosphine 0.03 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com