Wet-process ferric salt membrane-electrolysis regenerated biogas desulfurization method and device thereof

A biogas desulfurization and membrane electrolysis technology, which is applied in the field of wet iron salt membrane electrolysis regeneration biogas desulfurization and its devices, can solve the problems of low overall efficiency of desulfurization process, high temperature requirements, and no engineering applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation of the present invention will be described in conjunction with the examples.

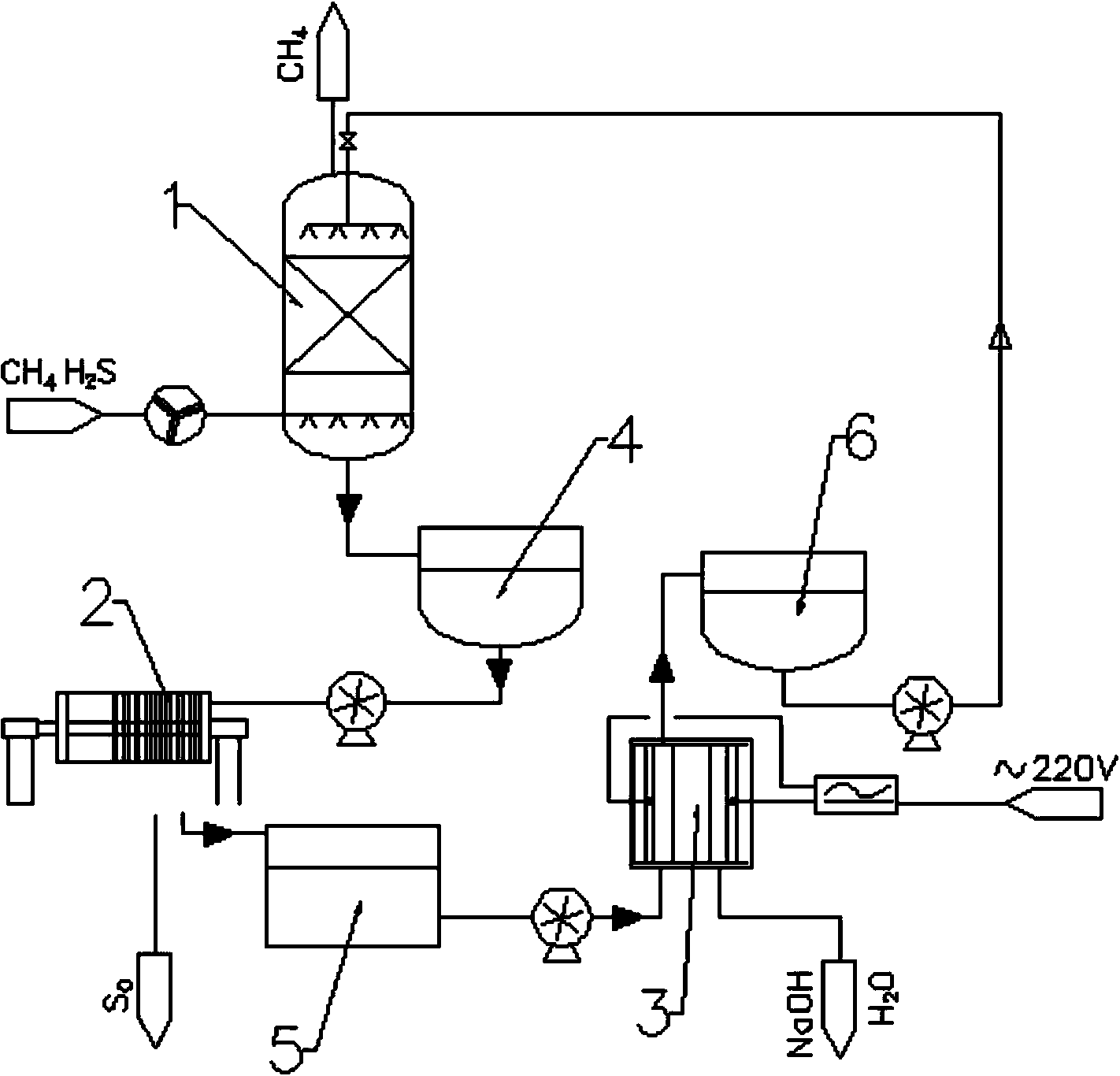

[0026] like figure 1 As shown, the wet-process iron-salt membrane electrolysis regeneration biogas desulfurization device includes an absorption tower 1, the waste liquid outlet of the absorption tower 1 communicates with the water inlet of the separation device 2 through the recovery tank 4, and the water outlet of the separation device 2 passes through the buffer tank 5 and The water inlet of the diaphragm electrolyzer 3 is connected, and the water outlet of the diaphragm electrolyzer 3 is connected with the water inlet of the absorption tower 1 through the liquid storage tank 6 .

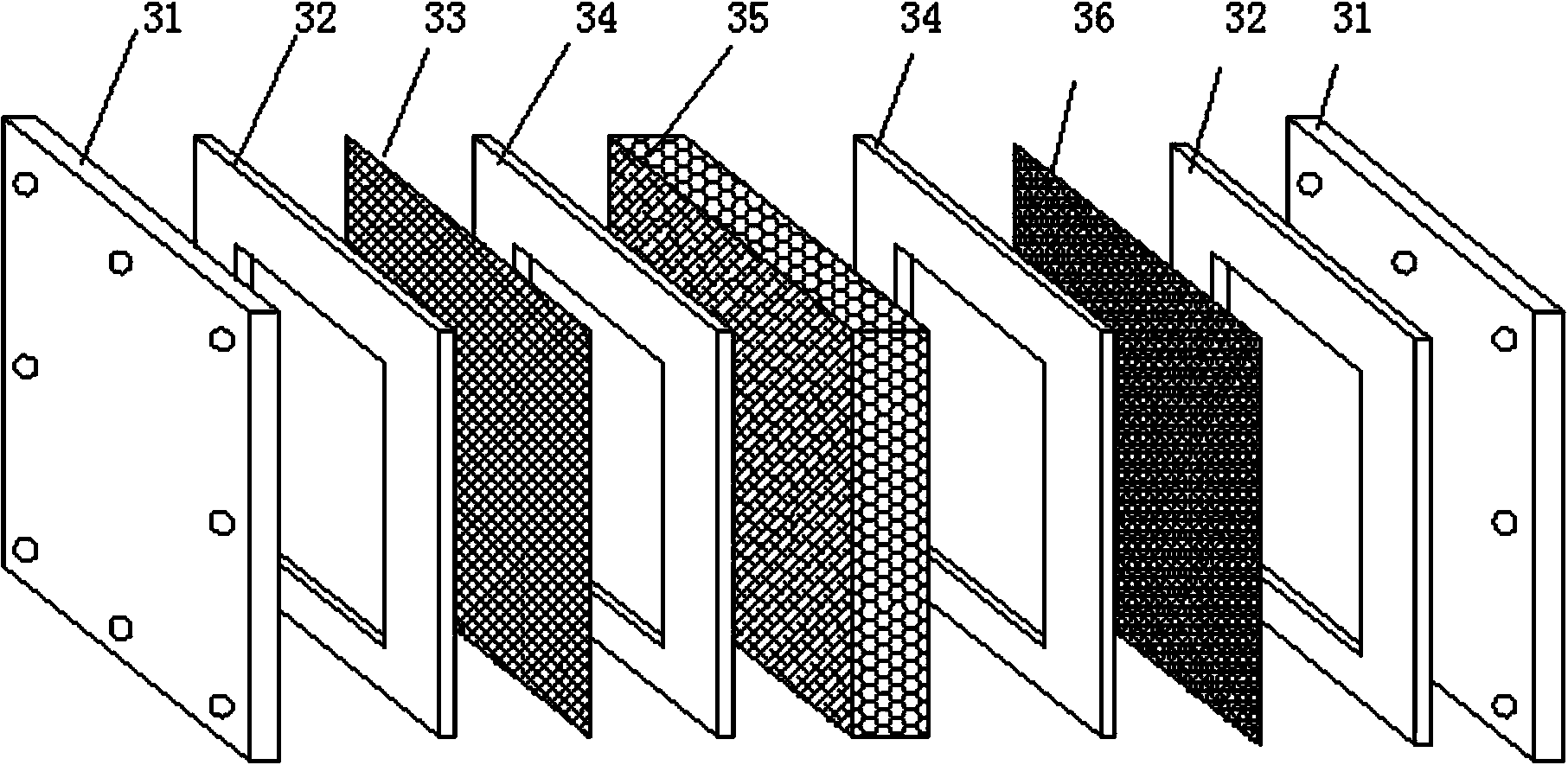

[0027] like figure 2 As shown, the diaphragm electrolyzer 3 includes a casing, a power supply, and two end plates 31 and sealing gaskets 32. The end plate 31 is an electrolyzer, and the electrolyzer includes a cathode plate 33 and an anode plate 36. There is a composite separation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com