Silver nanoparticle-zinc oxide porous nanosheet-carbon fiber cloth composite substrate as well as preparation method and use of substrate

A silver nanoparticle and zinc oxide nanotechnology, which is applied in metal material coating process, superimposed layer plating, coating and other directions, can solve the problems of effective surface area discount, structural stability is difficult to guarantee, specific surface area cannot be obtained, etc. Achieve the effect of scientific preparation method, stable structure and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The specific steps of preparation are:

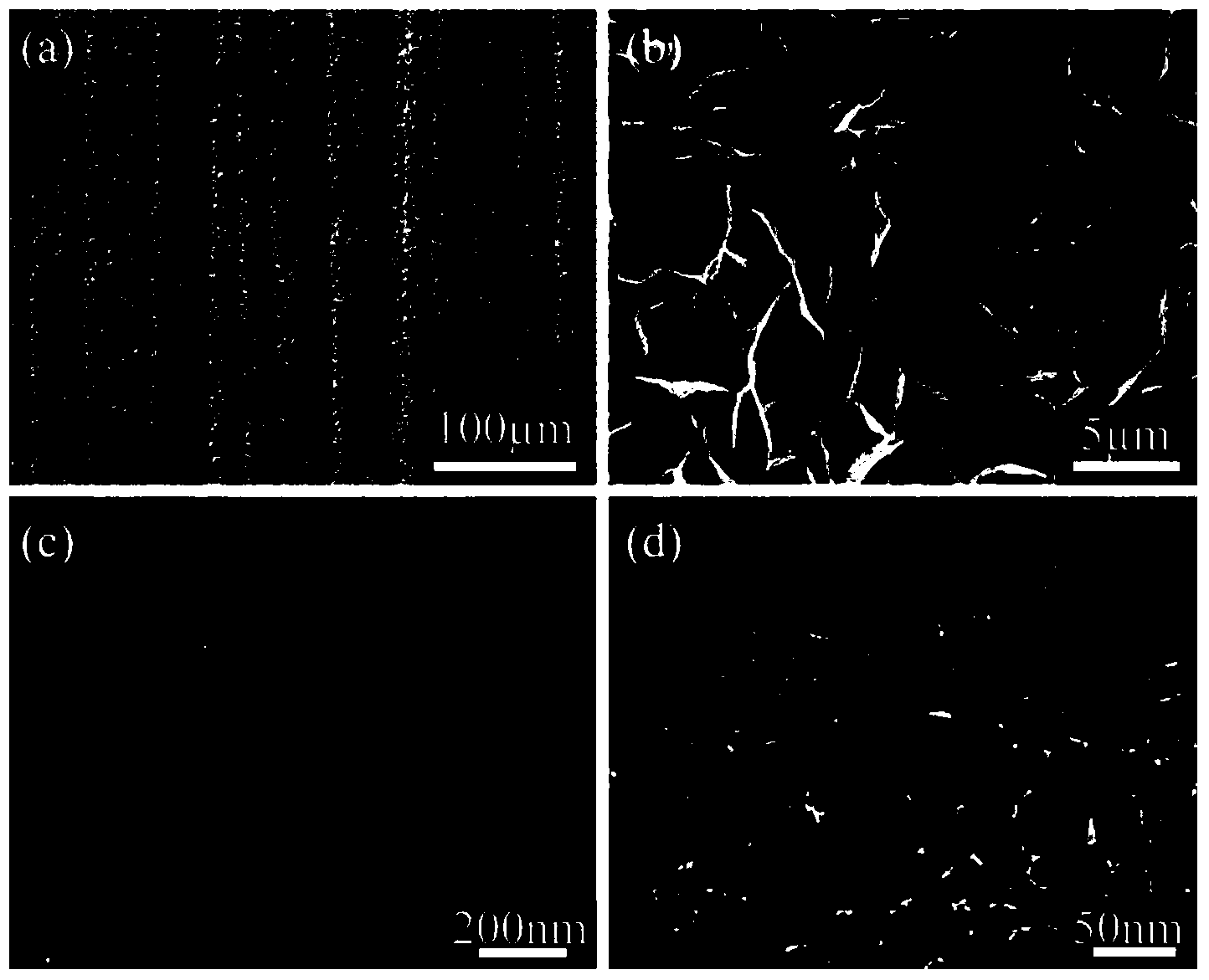

[0042] Step 1. Firstly, an atomic layer deposition technique is used to grow a zinc oxide seed layer with a thickness of ≥50 nm on the carbon fiber cloth. Suspend the carbon fiber cloth covered with the zinc oxide seed layer in the precursor solution and soak for 12 hours at a temperature of 80°C. The precursor solution consists of urea with a concentration of 1.5 mol / L and a concentration of 0.6 mol / L. The zinc nitrate is prepared in a volume ratio of 0.8:1.2 to obtain a carbon fiber cloth covered with a precursor.

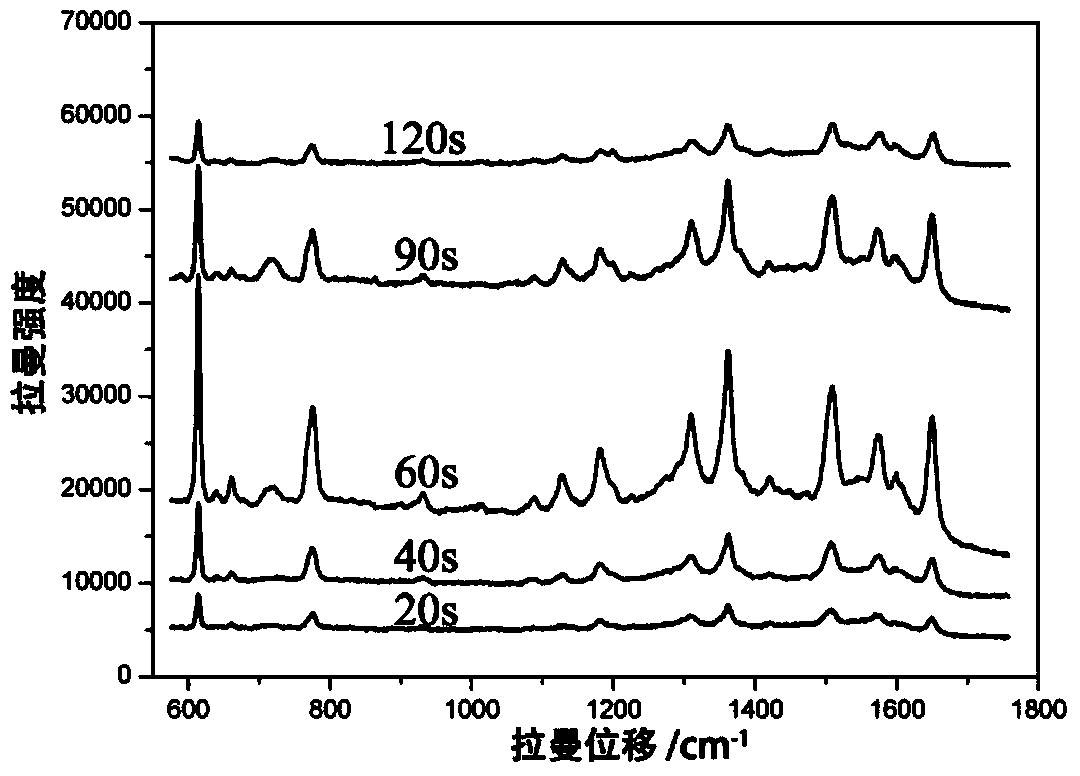

[0043] Step 2: First, rinse the carbon fiber cloth covered with the precursor with deionized water, and then anneal it at 330° C. for 34 minutes to obtain a carbon fiber cloth with zinc oxide porous nanosheets standing on the surface. Then, the silver nano-particles were ion sputtered on the carbon fiber cloth with the zinc oxide porous nano-sheets erected on the surface; wherein, the sputtering current during the sputt...

Embodiment 2

[0045] The specific steps of preparation are:

[0046] Step 1. Firstly, an atomic layer deposition technique is used to grow a zinc oxide seed layer with a thickness of ≥50 nm on the carbon fiber cloth. Then the carbon fiber cloth covered with zinc oxide seed layer was suspended in the precursor solution and soaked for 11.5h at a temperature of 85°C. The precursor solution was composed of urea with a concentration of 1.8mol / L and a concentration of 0.5mol / L. L zinc nitrate was prepared in a volume ratio of 0.9:1.1 to obtain a carbon fiber cloth coated with a precursor.

[0047] In step 2, the carbon fiber cloth covered with the precursor is washed with deionized water, and then annealed at 340° C. for 33 minutes to obtain a carbon fiber cloth with zinc oxide porous nanosheets standing on the surface. Then, the silver nano-particles were ion sputtered on the carbon fiber cloth with the zinc oxide porous nano-sheets erected on the surface; wherein, the sputtering current during the ...

Embodiment 3

[0049] The specific steps of preparation are:

[0050] Step 1. Firstly, an atomic layer deposition technique is used to grow a zinc oxide seed layer with a thickness of ≥50 nm on the carbon fiber cloth. Suspend the carbon fiber cloth covered with zinc oxide seed layer in the precursor solution and soak it for 11 hours at a temperature of 90°C. The precursor solution consists of 2mol / L urea and 0.4mol / L urea. Zinc nitrate is prepared at a volume ratio of 1:1 to obtain a carbon fiber cloth covered with a precursor.

[0051] Step 2: First, rinse the carbon fiber cloth covered with the precursor with deionized water, and then anneal it at 350° C. for 32 minutes to obtain a carbon fiber cloth with zinc oxide porous nanosheets erected on the surface. Then, the silver nano-particles were ion sputtered on the carbon fiber cloth with the zinc oxide porous nano-sheets erected on the surface; wherein, the sputtering current during the sputtering of the silver nano-particles was 40 mA and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com