System device for controlling combustion noise of common rail engine under transient condition

A technology of combustion noise and transient operating conditions, applied in engine components, engine control, combustion engines, etc., can solve problems such as increased pressure rise rate and high-frequency pressure oscillation, longer ignition delay period, and increased noise. To achieve the effect of reducing the pressure rise rate and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical principle and structure of the present invention will be described in more detail below in conjunction with the accompanying drawings and through embodiments. It should be noted that the examples are only for illustrative purposes, and are not intended to limit the protection scope of the present invention.

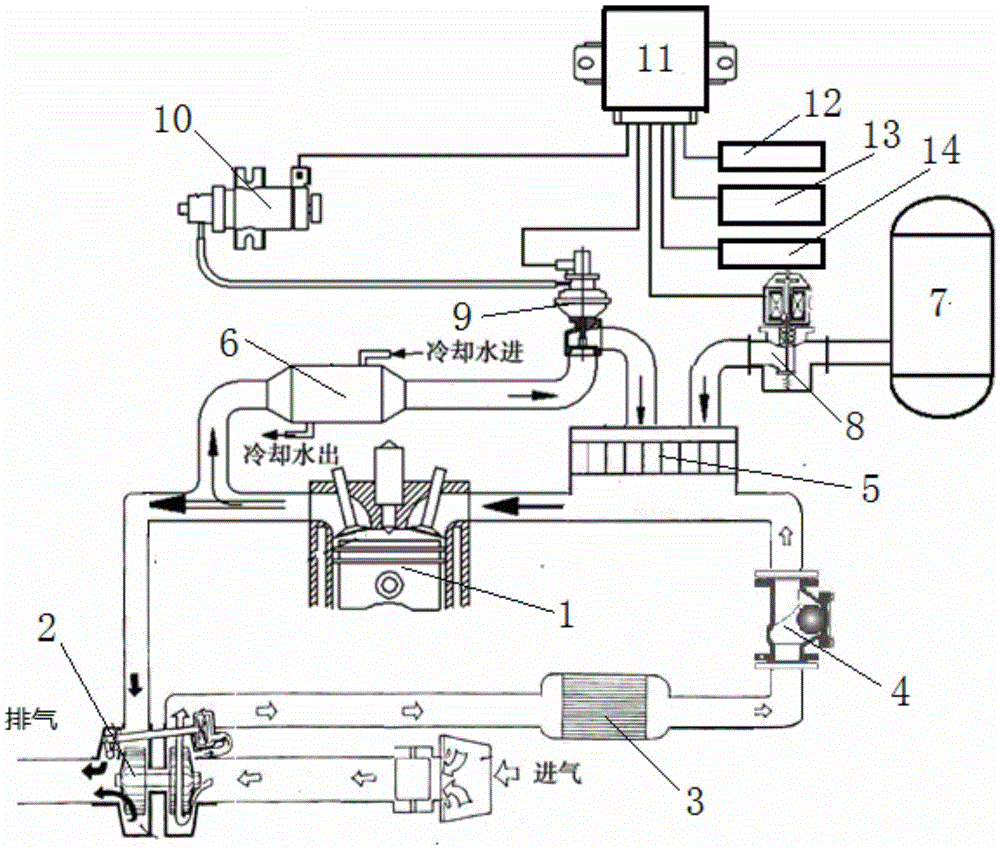

[0015] A system device and method for controlling combustion noise of a common rail engine under transient conditions. System devices include: engine, turbocharger, intercooler, check valve, EGR cooler, high-pressure gas storage tank, high-pressure solenoid valve, intake mixer, EGR valve, vacuum regulating valve, ECU control unit, water temperature sensor , accelerator sensor and speed sensor, etc. Its component connection structure is: the engine 1, the turbocharger 2, the intercooler 3, the one-way valve 4 and the intake mixer 5 are sequentially connected to form an engine secondary supercharging power cycle system. The engine exhaust branch pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com