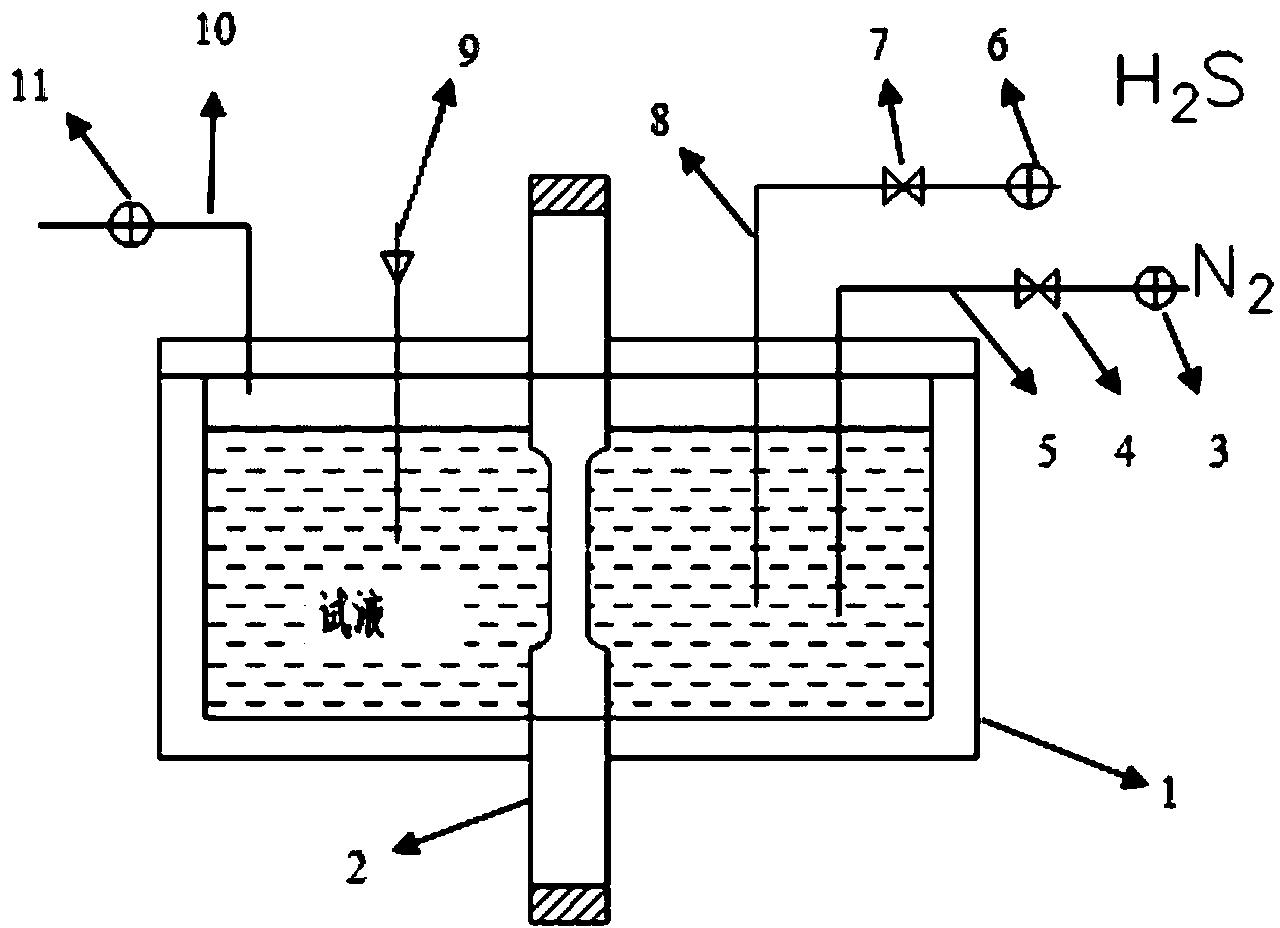

Hydrogen sulfide concentration control device for sulfide stress corrosion uniaxial tensile test

A technology of stress corrosion and uniaxial stretching, which is applied in the direction of testing wear resistance, etc., can solve the problems of high cost of sulfur-resistant drill pipe and low concentration of hydrogen sulfide, and achieve the effect of reducing hydrogen sulfide gas consumption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1, using the device of the present invention to configure a hydrogen sulfide aqueous solution with a concentration of about 0.01mol / L, the steps are as follows:

[0012] Since hydrogen sulfide aqueous solution is a weak acid, the ionization in water is as follows:

[0013] h 2 SH + +HS - The first order ionization constant is about 9.5×10 -8

[0014] HS - H + +S 2- The secondary ionization constant is about 7.1×10 -15

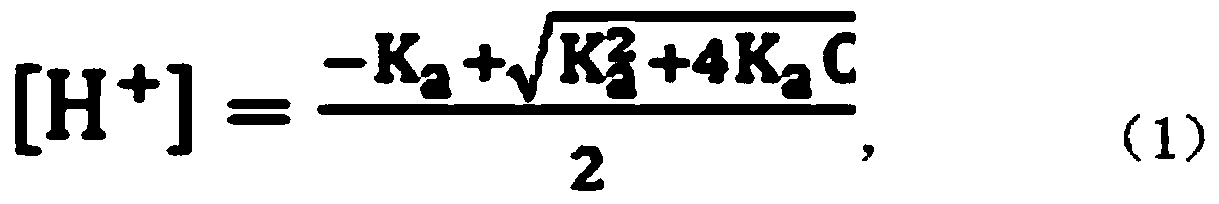

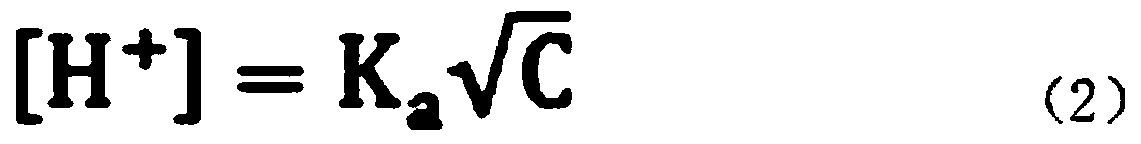

[0015] Therefore, its secondary dissociation can be ignored. Hydrogen sulfide gas can be electrolyzed as a monobasic weak acid in pure water. Assuming that the solution concentration is C, its H + The corresponding relationship between concentration, dissociation coefficient and solution concentration is as follows:

[0016] In analytical chemistry, [H + ] or [OH - ] The relative error allowed for calculation is generally within ±5%. When KaC in the solution>20Kw, [H + ] can be calculated using the approximate formula

[0017] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com