Method for recycling vanadium resources

A technology for resource recovery and vanadium trichloride, applied in the field of vanadium resource recovery and utilization, can solve the problems of pollution, long process and high energy consumption, and achieve the effects of avoiding hardening, improving recovery rate and realizing recovery and utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

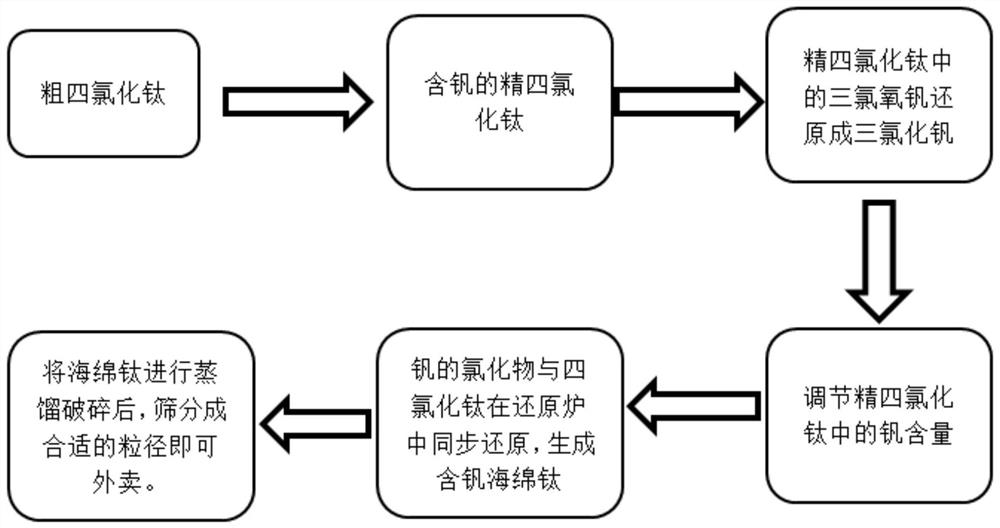

[0026] figure 1 It is a schematic process flow diagram of an embodiment of the present invention. The embodiment of the present invention is used to reclaim the vanadium element in titanium tetrachloride. The recovery process mainly includes: refining of titanium tetrachloride, reduction of vanadium oxytrichloride in titanium tetrachloride, The adjustment of vanadium content in titanium tetrachloride, the preparation of vanadium-containing sponge titanium, etc., when using the above process, include the following steps: first, do not add vanadium removal agent in the primary kettle, so as to prepare vanadium-containing refined tetrachloride Titanium, then add excess activated carbon to vanadium-containing refined titanium tetrachloride, VOCl 3 All reduced to VCl 3 According to the vanadium-containing sponge titanium requirement of 10% vanadium content, the vanadium content in titanium tetrachloride is increased to 0.75% by distillation, and this solution is added to the reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com