A polysilicon reduction furnace in which the tail gas outlet is connected to an inner extension pipe and its connection method

A reduction furnace and polysilicon technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve problems such as the dead zone of reflow in the reduction furnace, slow growth rate at the lower part of the silicon core, and high gas velocity at the inlet of the reduction furnace. Concentration and temperature gradient, solving the problem of silicon core thickness, the effect of stable and safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

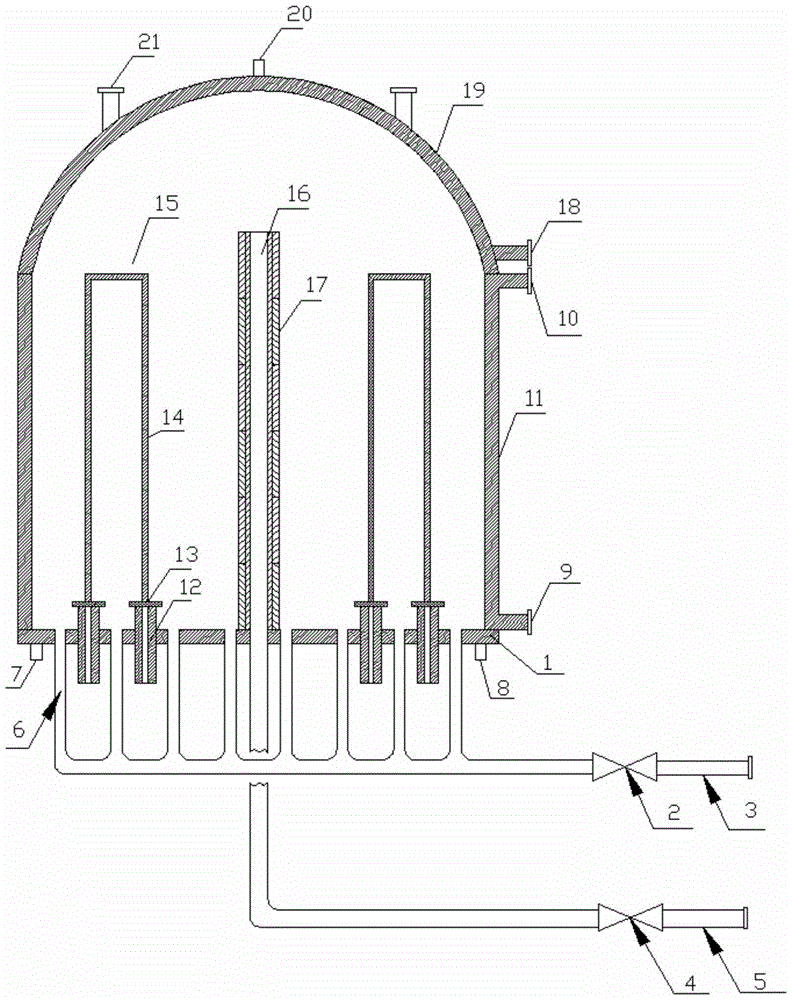

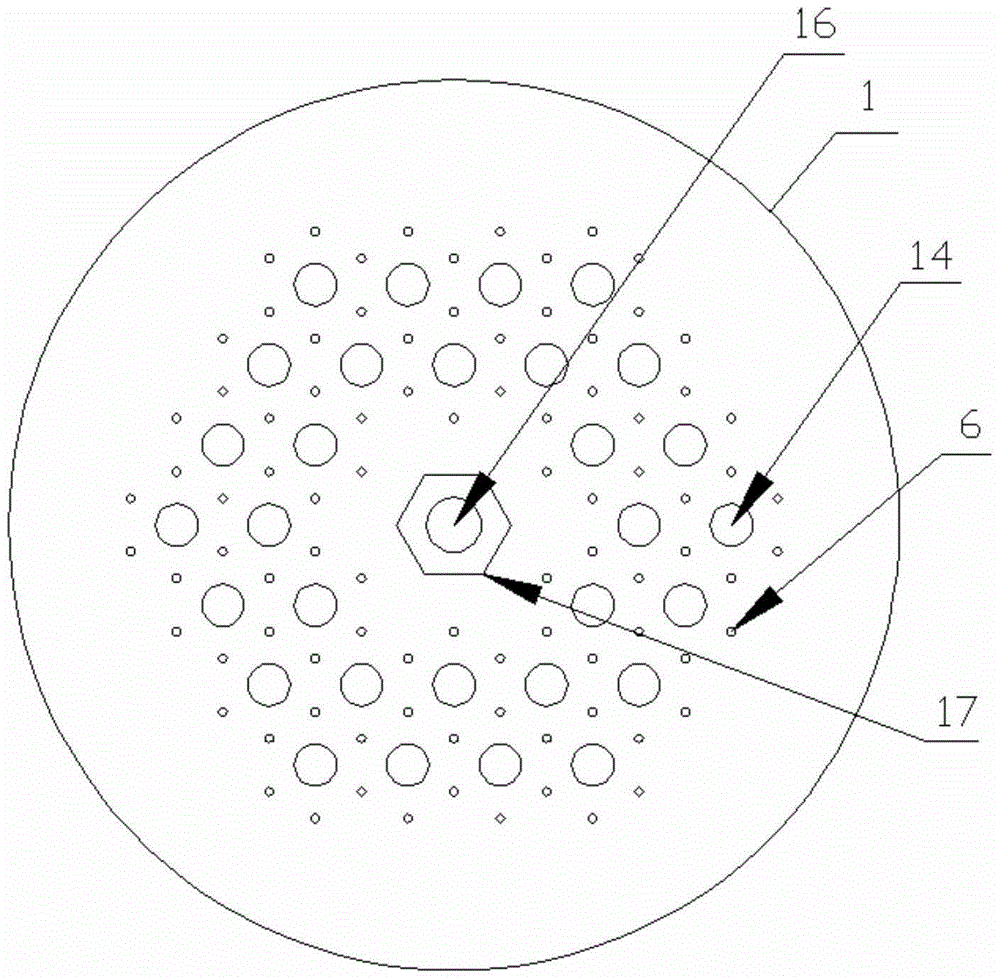

[0029] Example 1: Operation flow 1 of the new polysilicon reduction furnace (taking 15 pairs of rod polysilicon reduction furnaces as an example):

[0030] (1) Open the chassis mixed gas intake control valve 2 and the chassis exhaust gas outlet control valve 4;

[0031] (2) Cooling water is introduced into the furnace body of the reduction furnace, the bottom plate of the reduction furnace, and the top plate of the reduction furnace at the same time;

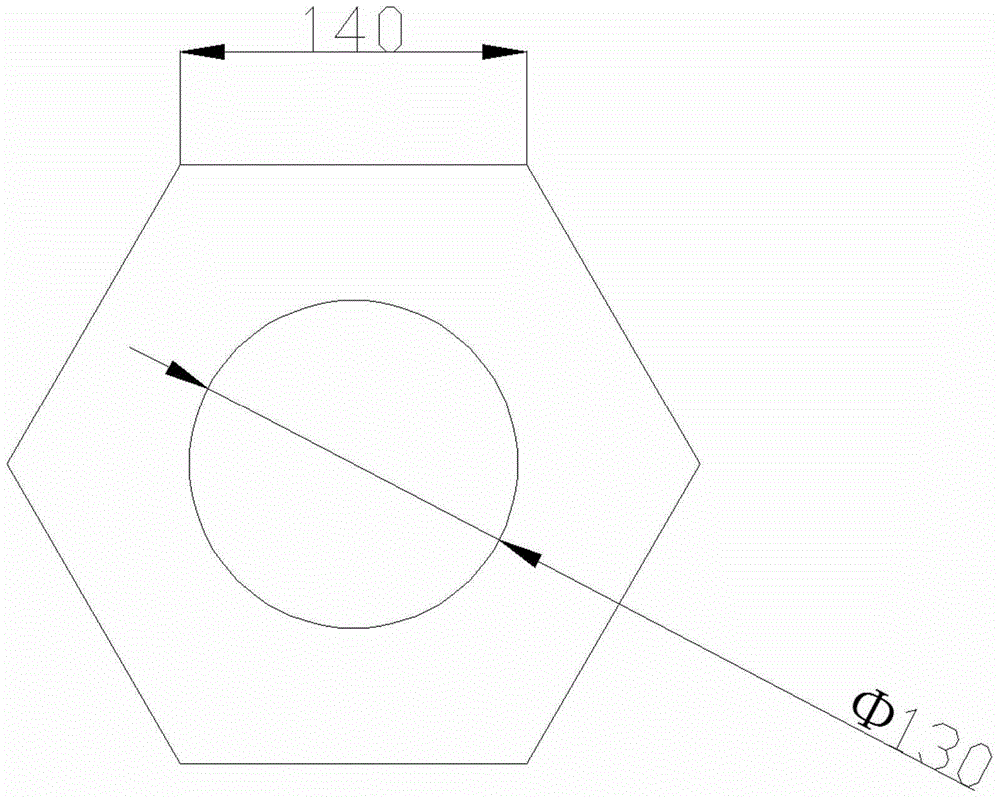

[0032] (3) The purified SiHCl 3 with H 2 Mix according to a certain ratio, and then spray into the reduction furnace from the mixed gas inlet pipe 3 through the chassis mixed gas inlet control valve 2 and the chassis inlet 6;

[0033] (4) Start the power supply system of the reduction furnace to heat the silicon core, and keep the temperature of the silicon core at 1150°C, and the pressure in the reduction furnace is 0.8Mpa;

[0034] (5) When the temperature of the silicon core surface reaches SiHCl 3 with H 2 Under the con...

Embodiment 2

[0037] Example 2: Operation process 2 of the new polysilicon reduction furnace (taking 15 pairs of rod polysilicon reduction furnaces as an example):

[0038] (1) Open the chassis mixed gas intake control valve 2 and the chassis exhaust gas outlet control valve 4;

[0039] (2) Cooling water is introduced into the furnace body of the reduction furnace, the bottom plate of the reduction furnace, and the top plate of the reduction furnace at the same time;

[0040] (3) The purified SiHCl 3 with H2 Mix according to a certain ratio, and then spray into the reduction furnace from the mixed gas inlet pipe 3 through the chassis mixed gas inlet control valve 2 and the chassis inlet 6;

[0041] (4) Start the power supply system of the reduction furnace to heat the silicon core, and keep the temperature of the silicon core at 1150°C, and the pressure in the reduction furnace is 0.8Mpa;

[0042] (5) When the temperature of the silicon core surface reaches SiHCl 3 with H 2 Under the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com