Equipment and method for separation and washing of fly ash alumina clinker dissolution slurry

A fly ash alumina and slurry separation technology, applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve the problem of long liquid-solid separation time in sedimentation separation process, high alumina secondary reaction loss, It is difficult to realize problems such as sedimentation and separation, and achieve the effect of improving the filtrate acquisition rate, improving the efficiency of vacuum filtration, and reducing the loss of alumina

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

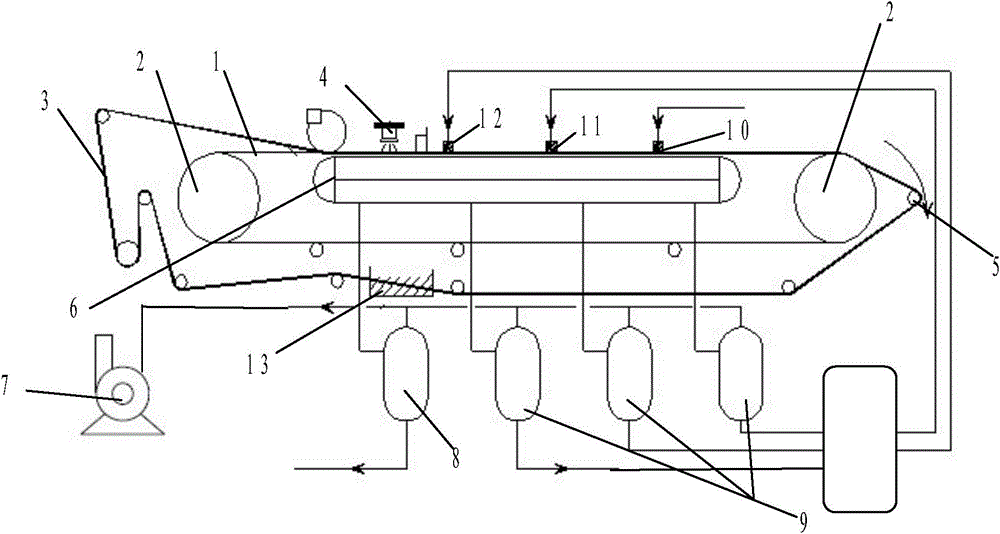

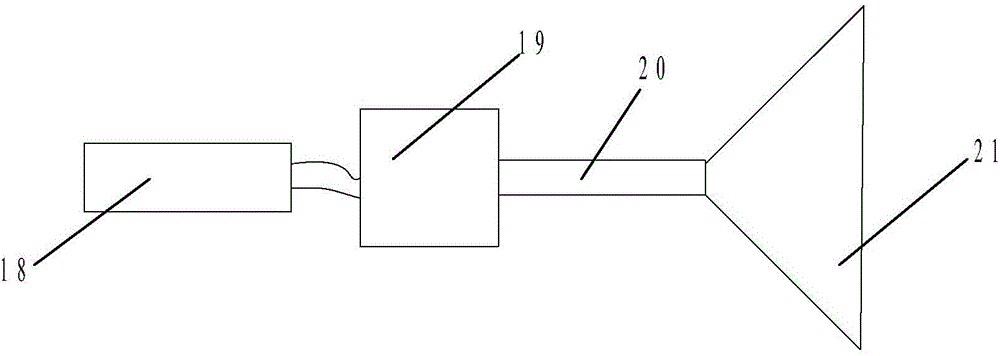

[0044] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides a kind of equipment for separation and washing of fly ash alumina clinker dissolution slurry, including:

[0045] A conveying device comprising a pair of rollers 2 and a conveyor belt 1 arranged on the pair of rollers 2;

[0046] The filter cloth 3 is sleeved on the conveyor belt 1 and rotates synchronously with the conveyor belt 1. The filter cloth 3 is located on both sides of the pair of rollers 2 and forms the feeding material under the action of at least two supports. Port 4 and discharge port 5; the feed port 4 is connected to the slurry tank for holding the leaching slurry, and the discharge port is connected to the filter cake tank for receiving solid residue;

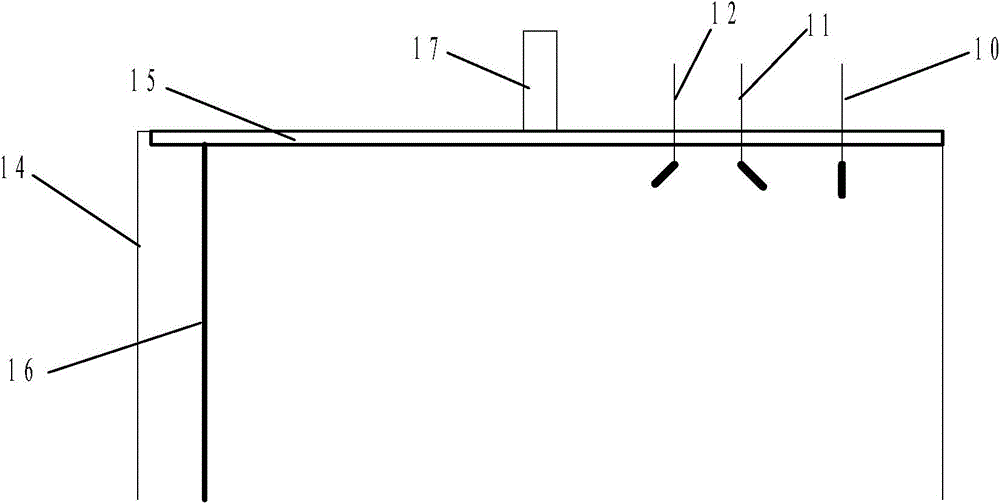

[0047]Housing 14, the housing 14 is arranged above the filter cloth 3, the top of the housing 14 is provided with a vertical shaft 17, the vertical shaft 17 is connected to the output end of a hydraulic cylinder, the hy...

Embodiment 2

[0064] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides equipment for separation and washing of fly ash alumina clinker dissolution slurry, including:

[0065] A conveying device comprising a pair of rollers 2 and a conveyor belt 1 arranged on the pair of rollers 2;

[0066] The filter cloth 3 is sleeved on the conveyor belt 1 and rotates synchronously with the conveyor belt 1. The filter cloth 3 is located on both sides of the pair of rollers 2 and forms the feeding material under the action of at least two supports. Port 4 and discharge port 5; the feed port 4 is connected to the slurry tank for holding the leaching slurry, and the discharge port is connected to the filter cake tank for receiving solid residue;

[0067] Housing 14, the housing 14 is arranged above the filter cloth 3, the top of the housing 14 is provided with a vertical shaft 17, the vertical shaft 17 is connected to the output end of a hydraulic cylinder, the hydraulic p...

Embodiment 3

[0084] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides equipment for separation and washing of fly ash alumina clinker dissolution slurry, including:

[0085] A conveying device comprising a pair of rollers 2 and a conveyor belt 1 arranged on the pair of rollers 2;

[0086] The filter cloth 3 is sleeved on the conveyor belt 1 and rotates synchronously with the conveyor belt 1. The filter cloth 3 is located on both sides of the pair of rollers 2 and forms the feeding material under the action of at least two supports. Port 4 and discharge port 5; the feed port 4 is connected to the slurry tank for holding the leaching slurry, and the discharge port is connected to the filter cake tank for receiving solid residue;

[0087]Housing 14, the housing 14 is arranged above the filter cloth 3, the top of the housing 14 is provided with a vertical shaft 17, the vertical shaft 17 is connected to the output end of a hydraulic cylinder, the hydraulic pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com