Method and device for preparing indium sulfate

A technology of indium sulfate and concentrated sulfuric acid, which is applied in chemical instruments and methods, gallium/indium/thallium compounds, inorganic chemistry, etc., can solve the problem that the quality of metal anode plates is not stable enough, the process is difficult to precisely control, and the structure of metal anode plates is coarse, etc. The problem is to reduce the pollution of other impurities, the process is simple and stable, and the content of impurities is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A kind of indium sulfate preparation method provided by the invention comprises steps:

[0036] A. Heating the indium raw material, filtering it, and dropping the filtrate onto a quartz plate with running water on the surface to produce indium with a high specific surface area;

[0037] B. Heating and stirring a mixed solution composed of high specific surface area indium, water and concentrated sulfuric acid, adding water during heating to keep the total amount of the mixed solution constant, to obtain an indium sulfate solution;

[0038] C, filter, evaporate indium sulfate solution, crystallization obtains indium sulfate pentahydrate;

[0039] D. Roasting and heat preservation of indium sulfate pentahydrate to obtain indium sulfate.

[0040] Indium is a silvery-white, bluish-tinged metal that is so soft that it can be scored with a fingernail. Indium has strong plasticity and ductility, and can be pressed into sheets.

[0041] The indium raw material is heated and ...

Embodiment 1

[0067] Follow the steps below:

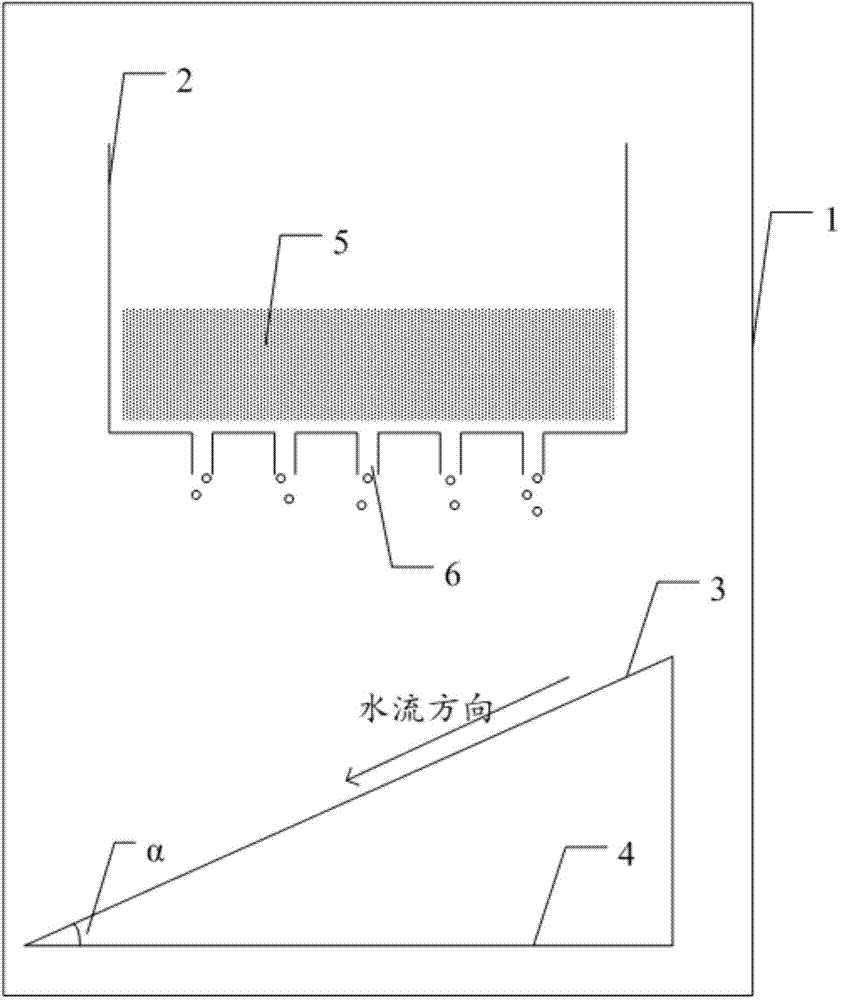

[0068] Step 1. Put the indium raw material indium block into a melting material funnel with an aperture of 1mm, heat up to 300°C, and drop the indium filtrate onto the quartz plate. The surface of the quartz plate is provided with running water and the plane where it is located is at an angle of 30° to the horizontal plane. The included angle, the flow speed is 1m / S, and the thickness of the flow water is 4mm, so that a high specific surface area of indium is obtained.

[0069] Step 2. Put high specific surface area indium, water and 98% concentrated sulfuric acid into the reaction kettle according to the ratio of 1kg:3000ml:700ml, heat to 150°C, and start stirring; add water continuously during the reaction process to keep the total amount of the solution unchanged; The reaction time was 2h, and an indium sulfate solution was obtained.

[0070] Step 3. Filter the indium sulfate solution, put the filtrate into an evaporation crystallization ...

Embodiment 2

[0074] The hole diameter of the melting material funnel funnel in step 1 is selected as 0.8 mm, and other conditions are the same as in Example 1, and the reaction, evaporative crystallization, and roasting are carried out to obtain indium sulfate.

[0075] The impurity content of indium sulfate was 0.000045% by sampling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com