Method for synchronously culturing nitrosified, anammox and denitrified granule sludge

An anaerobic ammonium oxidation and nitrosation particle technology is applied in the field of simultaneous nitrosation of domestic sewage, which can solve the problems of slow growth rate, high requirements on the biological retention capacity of the reactor, and less low-concentration ammonia nitrogen sewage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

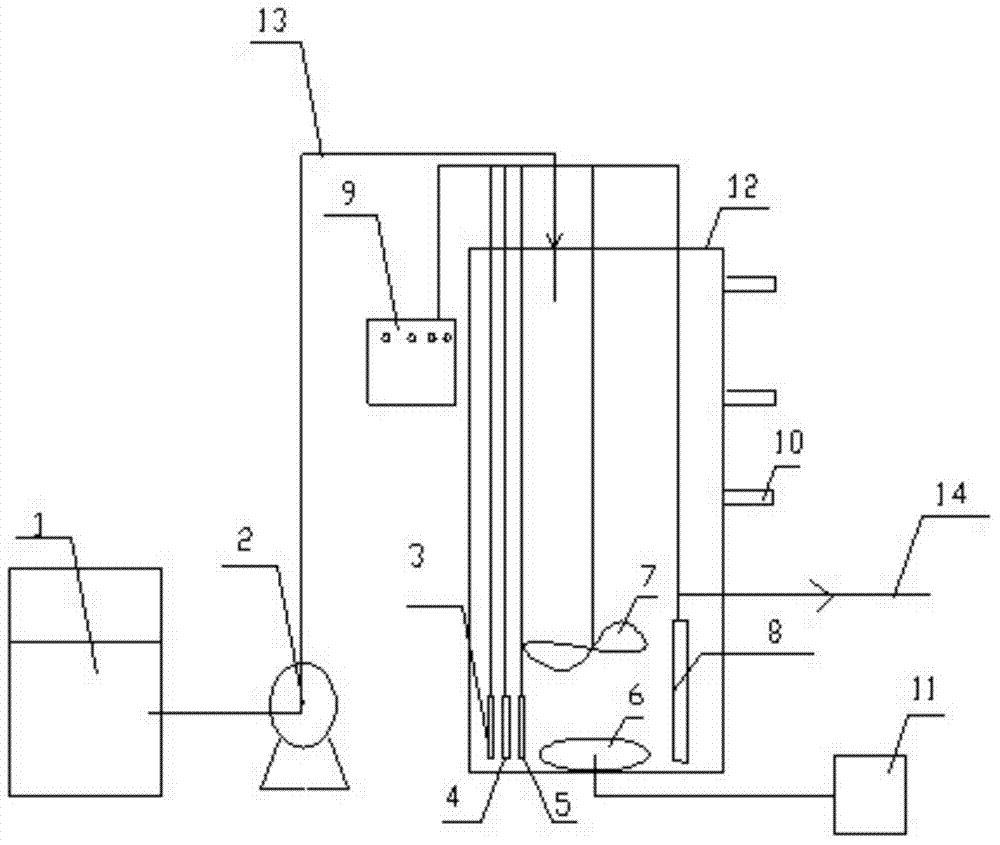

[0019] 1. Reactor device such as figure 1 shown.

[0020] 2. The influent used in the example is the domestic sewage of the residential area, the concentration of ammonia nitrogen in the influent is 60-80mg / l, the concentration of nitrate nitrogen is less than 1mg / l, the concentration of nitrous nitrogen is less than 1mg / l, and the concentration of COD is 160mg / l-250mg / l.

[0021] 3. The operation steps of the above method are as follows:

[0022] 1) Nitrosification granular sludge cultivation stage:

[0023] ① Inoculation sludge: Inoculate 4L of anammox granular sludge in an anammox reactor with stable operation, the particle size of the inoculation sludge is 1.0-2.0mm, and the sludge concentration is 40g / L. , the influent ammonia nitrogen concentration of the anaerobic ammonium oxidation reactor is 40-50mg / l, the nitrous concentration is 50-60mg / l, and the total nitrogen removal load is 0.35kg / (kgvss·d).

[0024] ②Working condition control: SBR reactor is adopted with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com