Culture medium for cultivating straw mushrooms and preparation method thereof

A culture material and technology of straw mushrooms, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve problems such as the lack of better development of straw mushroom nutritional value, increase costs, and push up the price of agricultural and sideline products, so as to achieve high output , prolong the fruiting period, and have the effect of rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

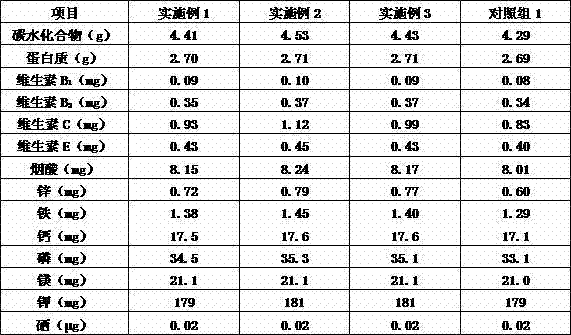

Examples

Embodiment 1

[0020] A culture medium for cultivating straw mushrooms, with cottonseed hulls, waste cotton, corn distiller's grains, and fescue hay as main ingredients, cow dung, plant ash, superphosphate, urea, gypsum powder, and quicklime as auxiliary materials, and naphthaleneacetic acid added preparation and forchlorfenuron, wherein the mass parts of each component are: 200 parts of cottonseed hulls, 40 parts of waste cotton, 20 parts of corn distiller's grains, 40 parts of fescue hay, 30 parts of cow dung, 10 parts of plant ash, and 8 parts of superphosphate 5 parts, 5 parts of urea, 12 parts of gypsum powder, 50 parts of quicklime, 0.5 parts of naphthalene acetic acid preparation and 1 part of forchlorfenuron. Among them, the naphthalene acetic acid preparation is a powder granule containing 70% naphthalene acetic acid sodium salt.

[0021] A preparation method for cultivating culture materials of straw mushrooms, comprising the following steps:

[0022] (1) Material preparation: wei...

Embodiment 2

[0028] A culture medium for cultivating straw mushrooms, with cottonseed hulls, waste cotton, corn distiller's grains, and fescue hay as main ingredients, cow dung, plant ash, superphosphate, urea, gypsum powder, and quicklime as auxiliary materials, and naphthaleneacetic acid added preparation and forchlorfenuron, wherein the mass parts of each component are: 400 parts of cottonseed hulls, 80 parts of waste cotton, 45 parts of corn distiller's grains, 75 parts of fescue hay, 90 parts of cow dung, 25 parts of plant ash, 20 parts of superphosphate 10 parts of urea, 30 parts of gypsum powder, 200 parts of quicklime, 2 parts of naphthalene acetic acid preparation and 3 parts of forchlorfenuron. Among them, the naphthalene acetic acid preparation is a powder granule containing 70% naphthalene acetic acid sodium salt.

[0029] A preparation method for cultivating culture materials of straw mushrooms, comprising the following steps:

[0030] (1) Material preparation: weigh the abov...

Embodiment 3

[0036] A culture medium for cultivating straw mushrooms, with cottonseed hulls, waste cotton, corn distiller's grains, and fescue hay as main ingredients, cow dung, plant ash, superphosphate, urea, gypsum powder, and quicklime as auxiliary materials, and naphthaleneacetic acid added preparation and forchlorfenuron, wherein the mass parts of each component are: 350 parts of cottonseed hulls, 55 parts of waste cotton, 35 parts of corn distiller's grains, 65 parts of fescue hay, 50 parts of cow dung, 15 parts of plant ash, 14 parts of superphosphate 6 parts of urea, 22 parts of gypsum powder, 140 parts of quicklime, 1 part of naphthalene acetic acid preparation and 2 parts of forchlorfenuron. Among them, the naphthalene acetic acid preparation is a powder granule containing 70% naphthalene acetic acid sodium salt.

[0037] A preparation method for cultivating culture materials of straw mushrooms, comprising the following steps:

[0038] (1) Material preparation: weigh the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com