Nano-porous material energy absorption structure packaged by high polymer materials

A polymer material and nano-porous technology, applied in the field of energy-absorbing structures, can solve problems such as non-reusable use, inability of materials to resist impact, permanent buckling of holes, etc., and achieve the effect of low material cost, light weight, and simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

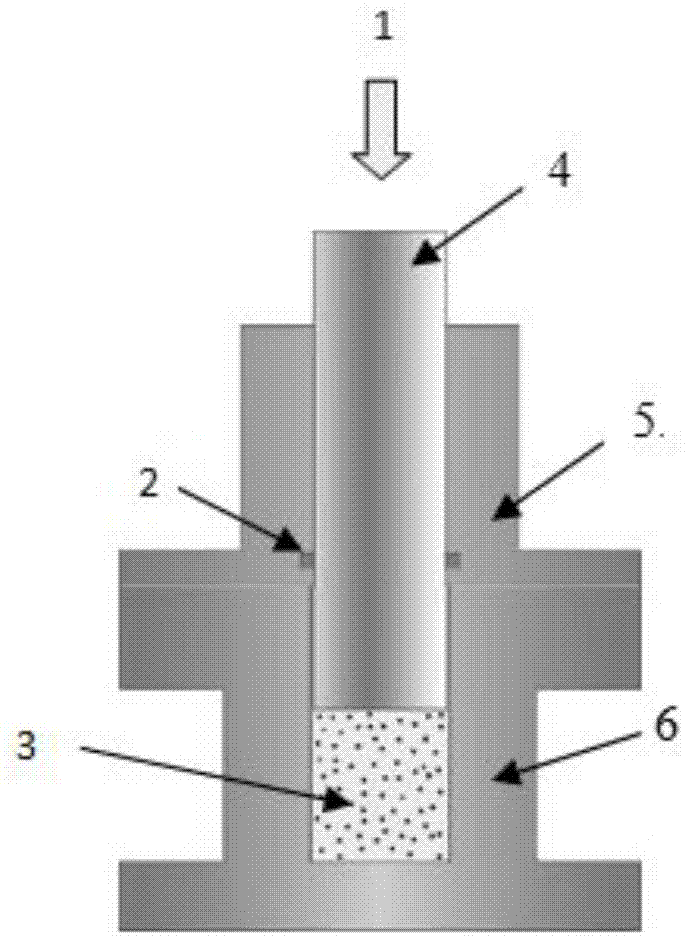

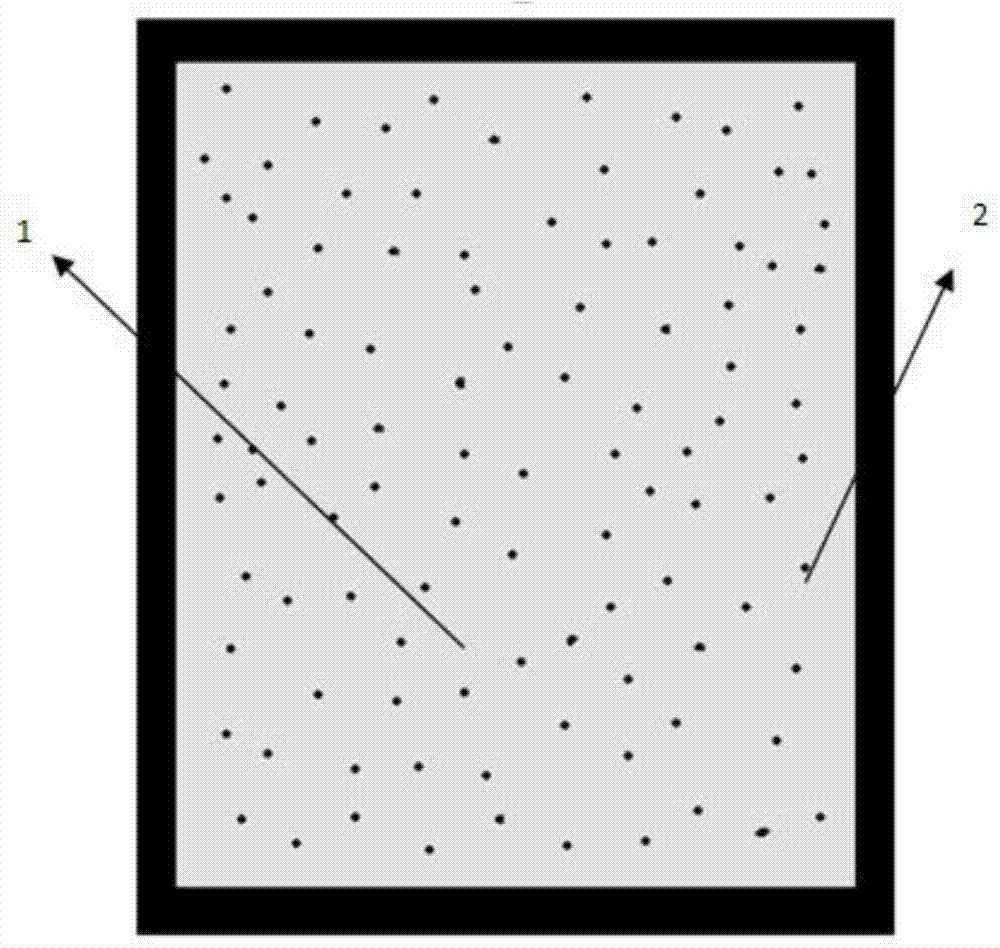

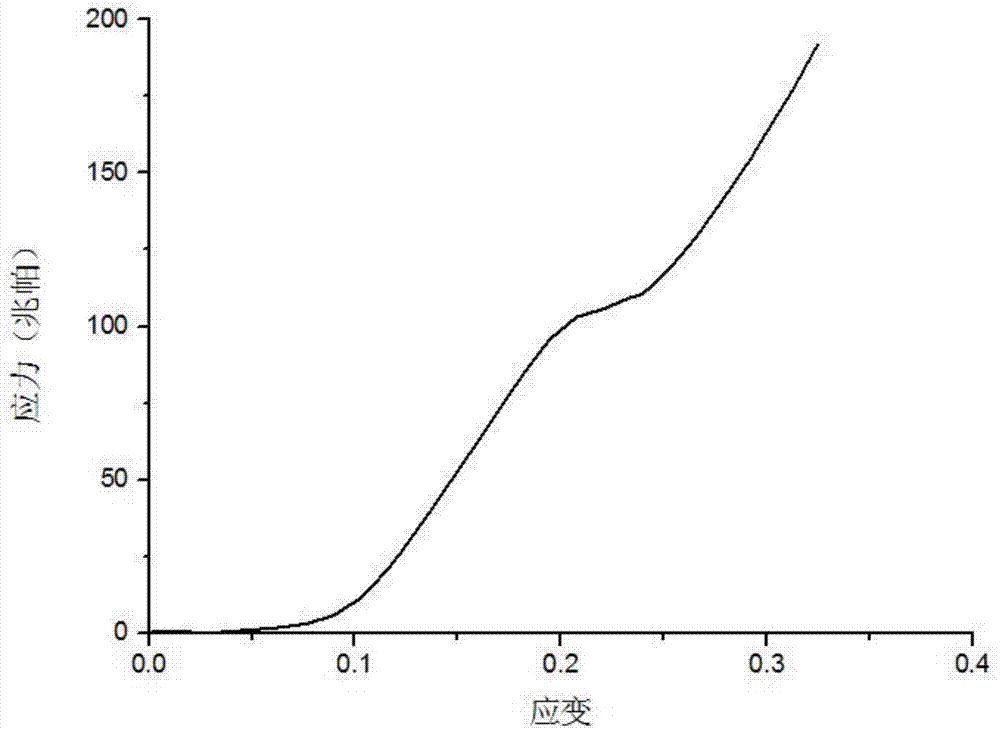

[0047] Such as figure 2 As shown, in this embodiment, a nanoporous material energy-absorbing structure encapsulated by a polymer material is used. The nanoporous material is ZSM-5 zeolite, and its average pore diameter is 0.5 nm. After mixing it with water, it is configured to have a concentration of 1 :1 solution, the polymer material shell 2 made of polyvinyl chloride is used to encapsulate the nanoporous material mixed solution 1, then the solid-liquid interfacial tension of the nanoporous material energy-absorbing structure can be used as a constant, and at this time, the solid-liquid interfacial tension The contact angle of the liquid interface mainly depends on the hydrophobicity of the channel. In the case of the same infiltration volume, ZSM-5 zeolite material has strong hydrophobicity, large contact angle, strong infiltration pressure, and large surface energy, and vice versa.

[0048] At the same time, at the nanometer scale, the fluid cannot be analyzed as a conti...

Embodiment 2

[0055] Such as figure 2 As shown, this embodiment is based on the energy-absorbing structure of nanoporous materials nested and packaged with metal and polymer materials. The nanoporous material is porous silica with an average pore diameter of 5 nm. It is mixed with sodium chloride solution and configured as For a solution with a concentration of 1:2, the nanoporous material mixture 1 is encapsulated by a polymer material shell 2 made of styrene-butadiene rubber.

Embodiment 3

[0057] Such as figure 2 As shown, this embodiment is based on the energy-absorbing structure of nanoporous materials nested and packaged with metal and polymer materials. The nanoporous material is carbon nanotubes with an average pore diameter of 40 nm. After mixing it with mercury, it is configured to have a concentration of 1 :5 solution, using the polymer material shell 2 made of natural rubber to encapsulate the nanoporous material mixture 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com