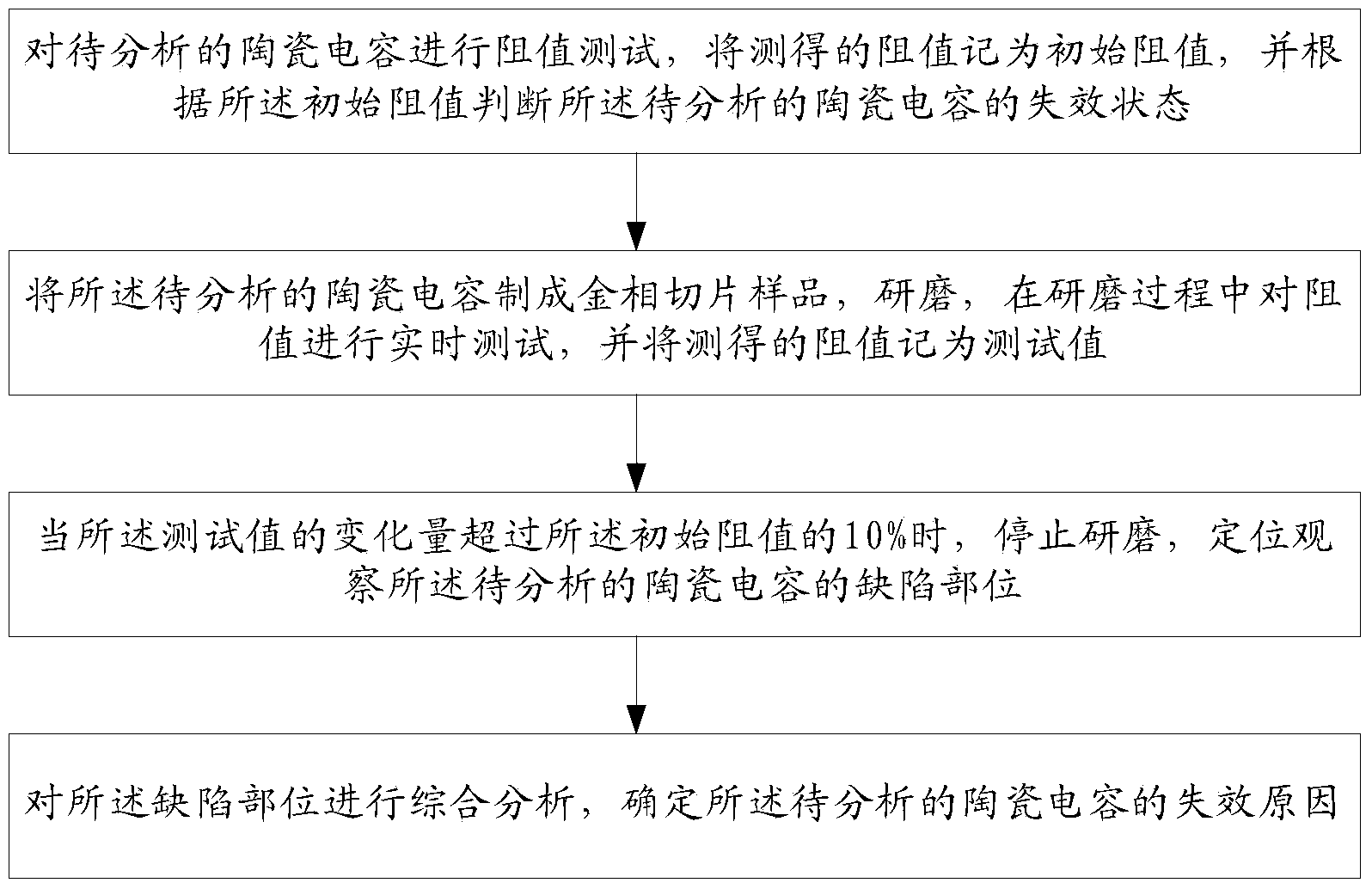

Analysis method of ceramic capacitor failure

A technology of ceramic capacitors and analysis methods, applied in the field of ceramic capacitors, can solve problems such as mechanical damage and thermal stress damage, and achieve the effect of strong applicability, easy operation, and avoiding stress interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Firstly, the appearance of the ceramic capacitor to be analyzed was checked by microscope, and no abnormality was found; secondly, the resistance value test of the ceramic capacitor to be analyzed was carried out to confirm that the ceramic capacitor was short-circuit failure; then the capacitor to be analyzed was poured with epoxy resin to make gold Phase slice samples. First use 400-mesh emery paper for rough grinding, grind to the inner electrode area of the ceramic capacitor, and then use 1200-mesh emery paper for fine grinding. The resistance value between the terminal electrodes A and B of the capacitor slice sample to be analyzed is measured every 8 seconds. Test; when it is found that the resistance value has increased from a short circuit to 500 ohms or more, stop grinding and perform OBIRCH analysis, such as figure 2 , image 3 As shown, the defective part of the ceramic capacitor is located, and the abnormal area located by the OBIRCH analysis is observed...

Embodiment 2

[0051] Firstly, the appearance of the ceramic capacitor to be analyzed was checked by microscope, and no abnormality was found; secondly, the resistance value test of the ceramic capacitor to be analyzed was carried out to confirm that the ceramic capacitor was short-circuit failure; then the capacitor to be analyzed was poured with epoxy resin to make gold Phase slice samples. First use 600-mesh emery paper for rough grinding, grind to the inner electrode area of the ceramic capacitor, and then use 1000-mesh emery paper for fine grinding, and measure the resistance between the terminal electrodes A and B of the capacitor slice sample to be analyzed every 10 seconds. Test; when the resistance value is found to increase from short circuit to 600 ohms or above, stop grinding, perform OBIRCH analysis, locate the defect of the ceramic capacitor, and observe and analyze the abnormal area located by OBIRCH analysis under the dark field of the metallographic microscope. It was foun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com