Exposure apparatus and focusing and leveling method thereof

A focus, leveling, and spot technology, applied in the field of photolithography, can solve problems such as falling outside the silicon wafer, invalid spot, and large amount of calculation for spot validity judgment, so as to improve time performance, improve measurement accuracy, and reduce effectiveness The effect of judging and switching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

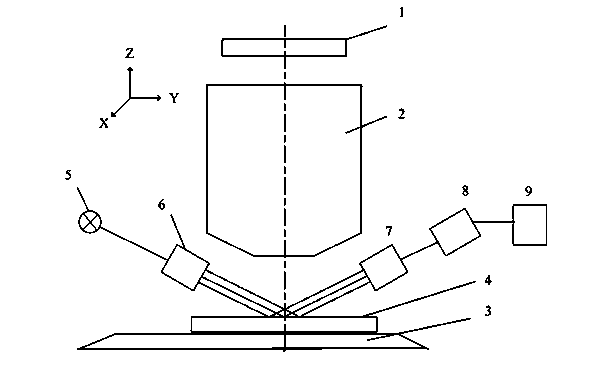

[0025] figure 1 Shown is a schematic structural view of the scanning exposure equipment used in the present invention, the scanning exposure equipment has a mask 1, a projection objective lens 2, a workpiece table 3, a silicon wafer 4, a light source 5, a projection unit 6, a detection unit 7, and a signal processing unit 8 , main controller 9 . The projection objective lens 2 is used to project the pattern of the mask 1 onto the upper surface of the silicon wafer 4 located on the workpiece table 3, the light emitted by the light source 5 is incident on the silicon wafer 4 through the projection unit 6, and is reflected by the upper surface of the silicon wafer 4 Afterwards, it is received by the detection unit 7, and after photoelectric conversion and signal processing are performed on the received optical signal by the signal processing uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com