Coating for converting optical energy into electric energy and glass assembly

A coating and light energy technology, applied in electrical components, coatings, circuits, etc., can solve the problems of only 1% solar energy conversion rate, short sunlight utilization time, low solar energy utilization rate, etc. The effect of high conversion rate and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

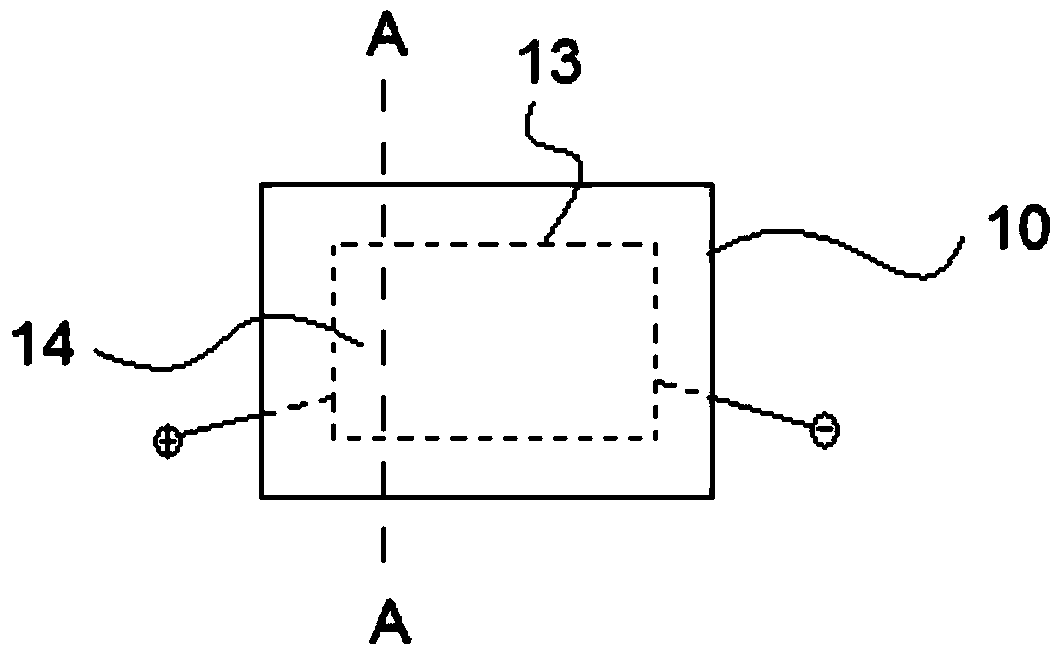

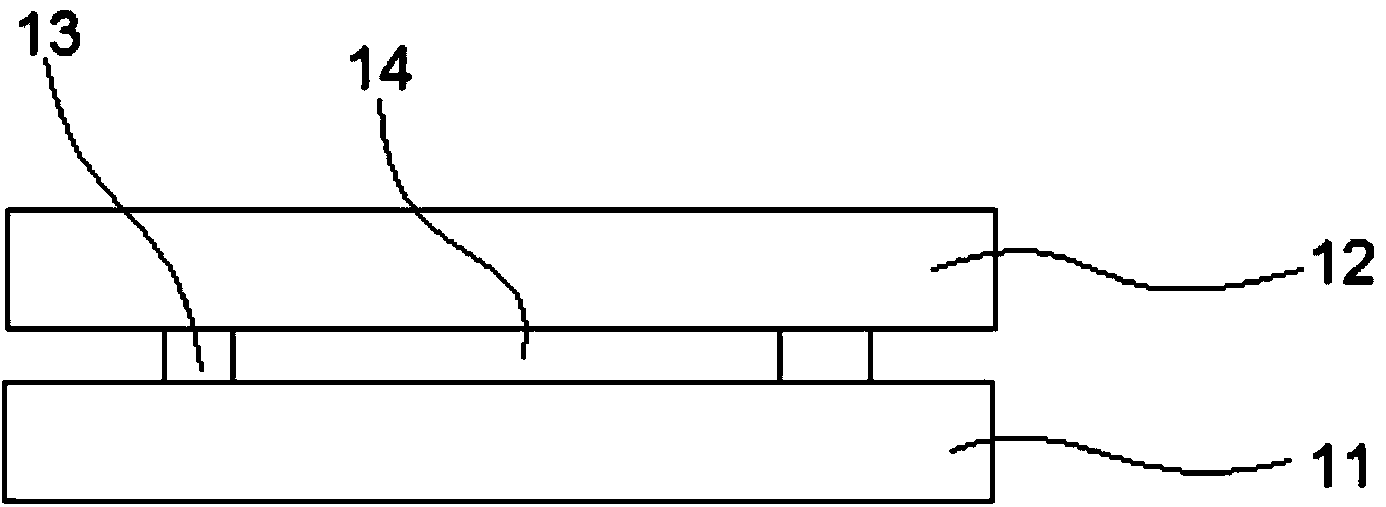

Image

Examples

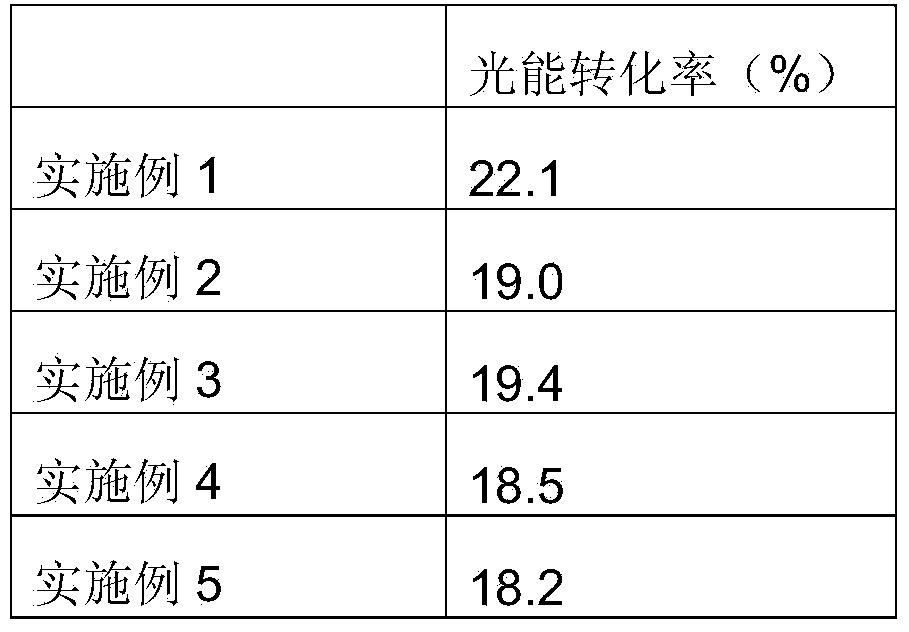

Embodiment 1

[0022] A coating for converting light energy into electrical energy. The components of the coating include 93%, 2% of cadmium sulfide or cadmium selenide, 4% of water, and 1% of alcohol in terms of mass percentage.

[0023] Coat cadmium sulfide or cadmium selenide on the surface of titanium dioxide nanoparticles, and then suspend it in a mixed liquid of water and alcohol to form a viscous paste; brush the viscous paste on a transparent conductive material, And by exposing it to light, electricity can be generated.

Embodiment 2

[0025] The difference between this example and Example 1 lies in that the components of the coating include 90% of titanium dioxide nanoparticles, 5% of cadmium sulfide or cadmium selenide, 4% of water, and 1% of alcohol.

Embodiment 3

[0027] The difference between this example and Example 1 is that the components of the coating include 93% of titanium dioxide nanoparticles, 2% of cadmium sulfide or cadmium selenide, 3% of water, and 2% of alcohol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com