A kind of oil-resistant stomach-soluble film coating premixed auxiliary material and preparation method thereof

A technology of coating premixed excipients and stomach-soluble films, which is applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, drug delivery, etc., to achieve the effects of improving compactness, reducing molecular gaps, and facilitating preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: a kind of oil-resistant stomach-dissolving type film coating premixed auxiliary material, it is made up of the raw material of following weight part:

[0026] HPMCE5: 9; HPMCE15: 14;

[0027] HPMCE50: 15; 3000 mesh talcum powder: 20;

[0028] Polyethylene glycol: 9; Titanium dioxide: 3.

[0029] The preparation method of the above-mentioned oil-resistant stomach-soluble film coating premixed auxiliary material comprises the following steps:

[0030] S1. Weighing: Accurately weigh each raw material according to the above ratio, and set aside;

[0031] S2. Premixing: Put the above-mentioned weighed raw materials into a ziplock bag and mix for 4 minutes;

[0032] S3. Pulverization: put the premixed raw materials into an ultrafine pulverizer and grind them for 100 minutes, and pass the ground raw materials through a 70-mesh sieve to obtain a coating powder;

[0033] S4. Preparation: dissolve the coating powder in purified water, and stir for 40 minutes to ...

Embodiment 2

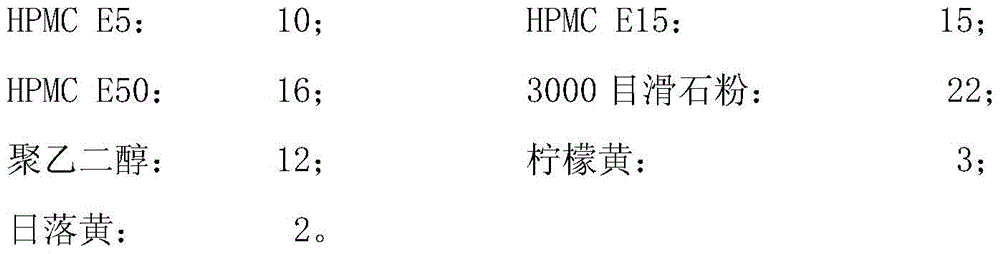

[0035] Embodiment 2: a kind of oil-resistant stomach-soluble film coating premixed auxiliary material, it is made up of the raw material of following weight portion:

[0036]

[0037] The preparation method of the above-mentioned oil-resistant stomach-soluble film coating premixed auxiliary material comprises the following steps:

[0038] S1. Weighing: Accurately weigh each raw material according to the above ratio, and set aside;

[0039] S2. Premixing: Put the above-mentioned weighed raw materials into a ziplock bag and mix for 8 minutes;

[0040] S3. Pulverization: put the premixed raw materials into an ultrafine pulverizer and grind for 120 minutes, pass the ground raw materials through a 100-mesh sieve to obtain a coating powder;

[0041] S4. Preparation: dissolve the coating powder in purified water, stir for 50 minutes, and prepare a coating solution with a concentration of 20%;

[0042] S5. Spraying: Spray the coating liquid on the tablets with a sugar coating pan...

Embodiment 3

[0043] Embodiment 3: a kind of oil-resistant stomach-soluble type film coating premixed auxiliary material, it is made up of the raw material of following weight portion:

[0044]

[0045] The preparation method of the above-mentioned oil-resistant stomach-soluble film coating premixed auxiliary material comprises the following steps:

[0046] S1. Weighing: Accurately weigh each raw material according to the above ratio, and set aside;

[0047] S2. Premixing: Put the above-mentioned weighed raw materials into a ziplock bag and mix for 6 minutes;

[0048] S3. Pulverization: put the premixed raw materials into an ultrafine pulverizer and grind for 108 minutes, pass the ground raw materials through an 80-mesh sieve to obtain a coating powder;

[0049] S4. Preparation: dissolve the coating powder in purified water, stir for 44 minutes, and prepare a coating solution with a concentration of 15%;

[0050] S5. Spraying: Spray the coating solution on the tablets with a sugar coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com