Preparation method and application of palladium adsorption material

An adsorption material and stirring reaction technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., to achieve the effect of easy elution and improvement of mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

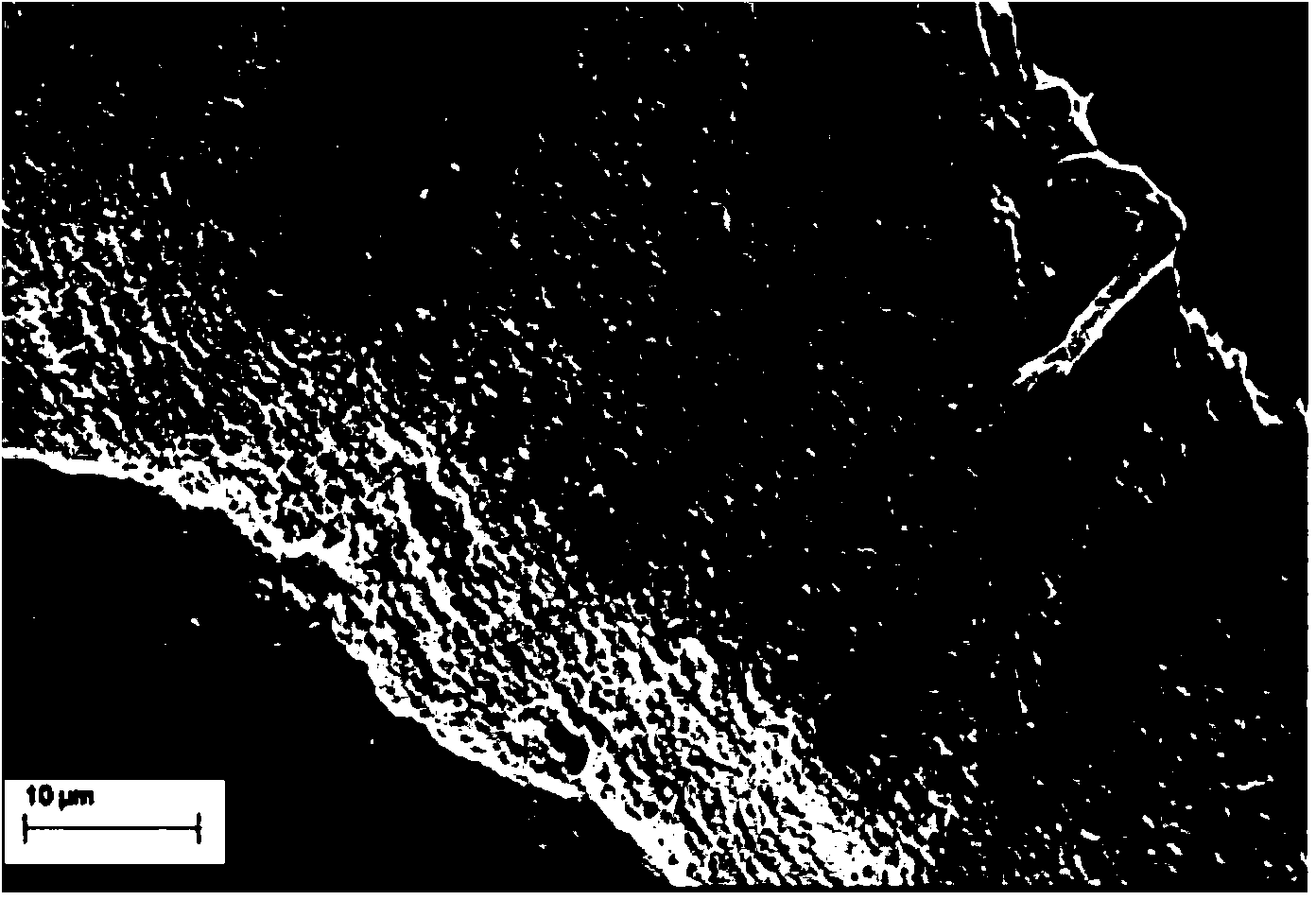

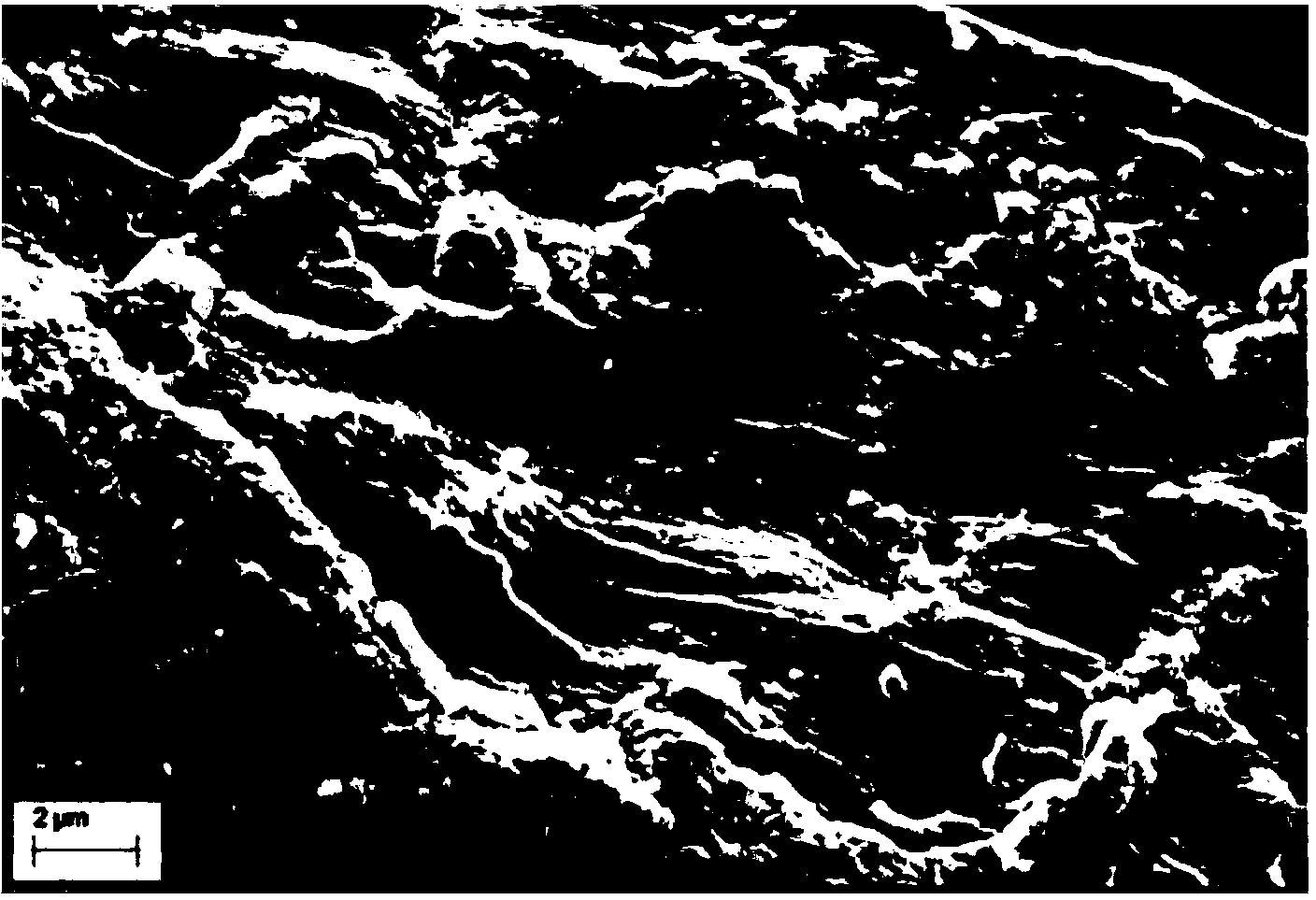

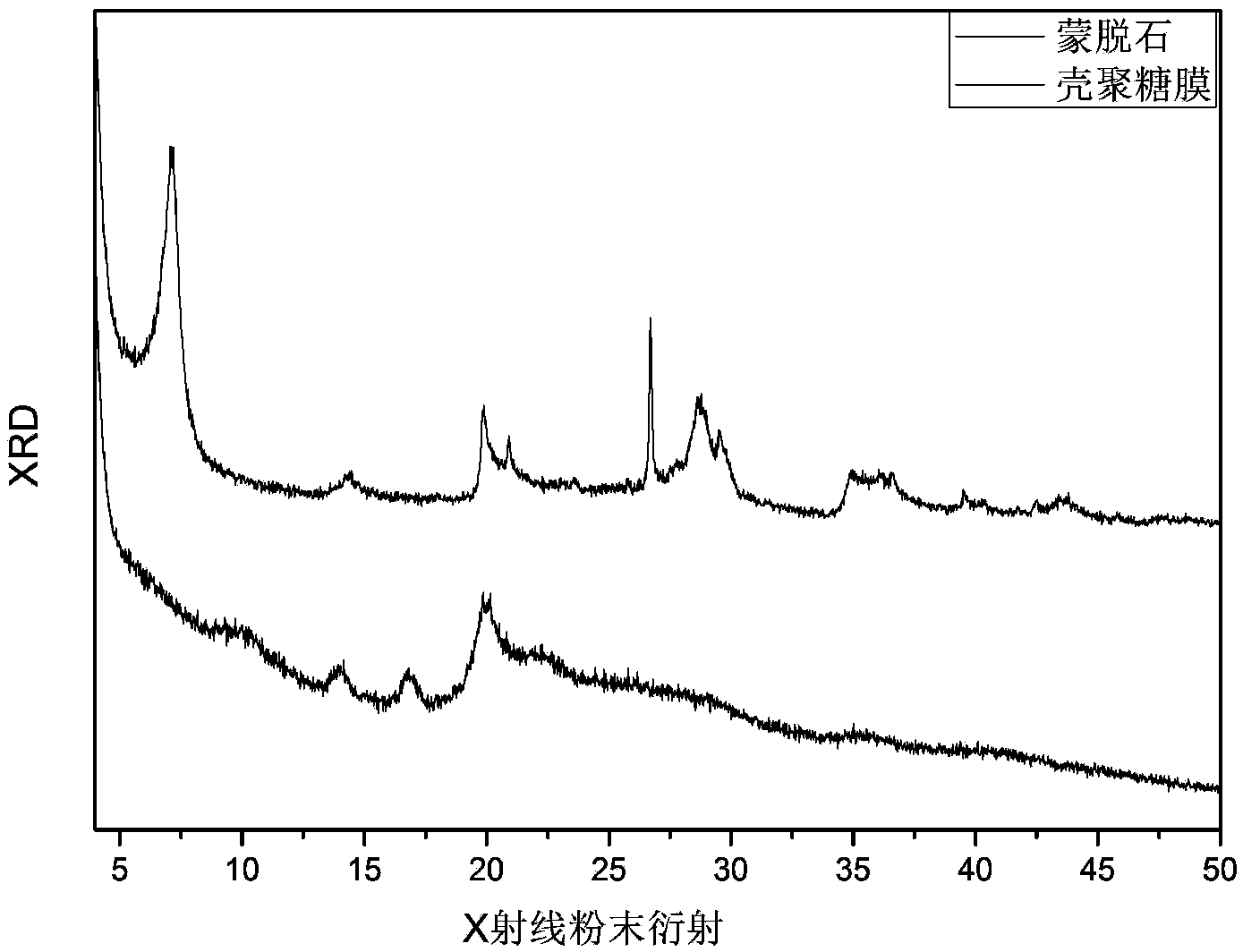

[0033] The preparation method of palladium adsorption material (chitosan-montmorillonite cross-linked blend film), comprises the following steps:

[0034] (1) Dissolve 1g chitosan in 40ml 2v / v% acetic acid, stir until a transparent solution is formed to obtain solution A; soak 0.1g montmorillonite with 10ml 2v / v% acetic acid, and sonicate for 2h until it is completely dispersed in the solution to obtain solution B;

[0035] (2) While stirring, add solution B to solution A dropwise, heat up to 50°C, and stir magnetically for 2 hours to obtain solution C;

[0036] (3) While stirring, add 0.5ml of 1wt% glutaraldehyde solution dropwise to solution C, and continue stirring for 4 hours to form a uniform yellow casting solution;

[0037] (4) Apply the casting solution on the support body, place it in an oven at 55°C and dry it to form a uniform and transparent yellow film material;

[0038] (5) Immerse the yellow membrane material in 4wt% NaOH solution, solidify for 2 hours, and fo...

Embodiment 2

[0040] In step (3), the amount of glutaraldehyde added is 0.1ml, 0.4ml, 0.5ml, 0.6ml, 0.8ml, 1.0ml of 1wt% glutaraldehyde aqueous solution, and other steps are the same as in Example 1.

[0041] As the amount of glutaraldehyde increases, the yellow color of the palladium adsorption material obtained in step (5) gradually deepens. After increasing to 0.6ml, the film is easy to break. Therefore, considering the physical properties and acid solubility of the adsorption material, chitosan and pentamethylene The mass ratio of dialdehyde is preferably 1000:(1-10), most preferably 1000:(5-6).

Embodiment 3

[0043] The preparation method of palladium adsorption material, comprises the following steps:

[0044] (1) Dissolve 2g chitosan in 100ml 3v / v% acetic acid, stir until a transparent solution is formed to obtain solution A; soak 0.1g montmorillonite with 10ml 3v / v% acetic acid, and sonicate for 2h until it is completely dispersed in the solution to obtain solution B;

[0045] (2) Under stirring, add solution B to solution A dropwise, heat up to 40°C, and stir magnetically for 2 hours to obtain solution C;

[0046] (3) While stirring, add 0.6ml of 2wt% glutaraldehyde solution dropwise to solution C, and continue stirring for 3 hours to form a uniform yellow casting solution;

[0047] (4) Apply the casting solution on the support body, place it in an oven at 80°C and dry it to form a uniform and transparent yellow film material;

[0048] (5) Immerse the yellow membrane material in 1wt% NaOH solution, solidify for 4 hours, and form a 0.5mm thick yellow translucent membrane mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com