Preparation method of fuel cell Pt/Graphene catalyst

A fuel cell and catalyst technology, which is applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of lack of marketization of fuel cells, poor corrosion resistance of activated carbon, and high price of platinum. , to achieve the effect of good oxygen reduction performance, reducing viscosity and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

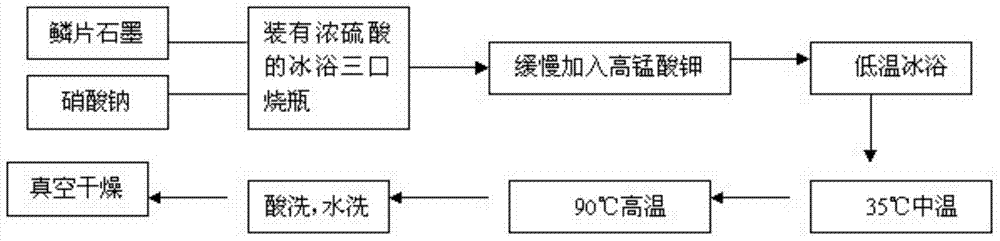

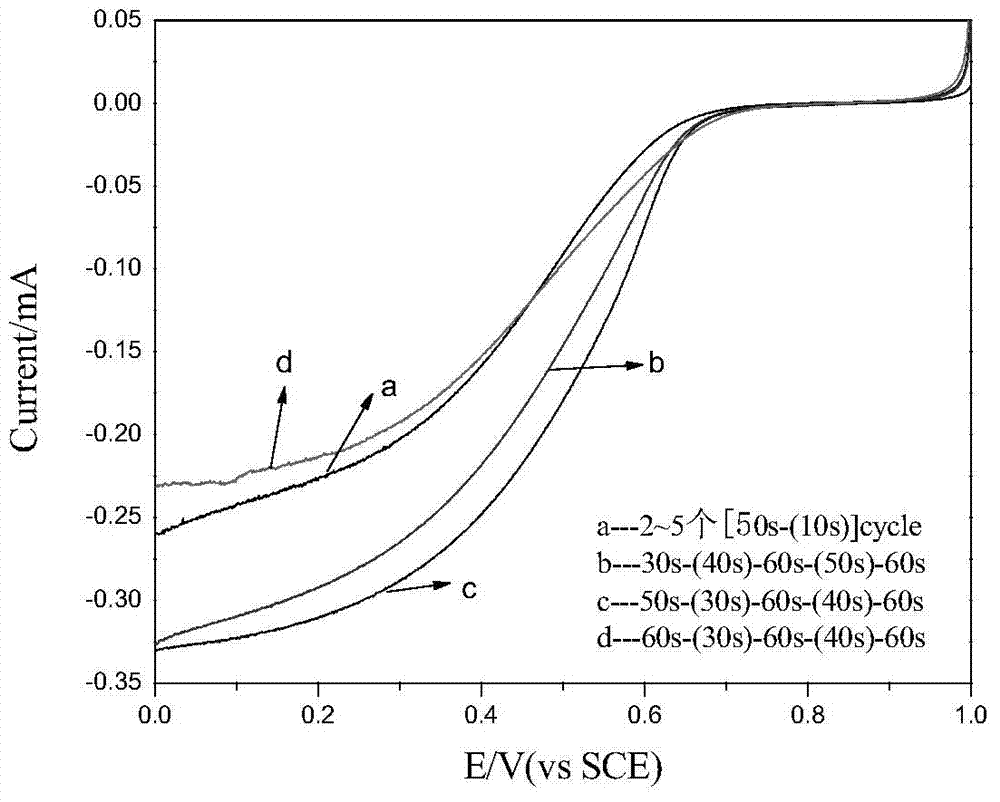

[0034] Such as figure 1 As shown, the present embodiment prepares the Pt / Graphene catalyst according to the following steps:

[0035] (1) Preparation of graphite oxide

[0036] It has been more than 150 years since Brodie prepared graphite oxide (Graphite Oxide, GO) in 1855, and various methods for preparing graphite oxide have been studied during this period. There are three main preparation methods at present, namely: Brodie method, Staudenmaier method and Hummers method. Among them, the timeliness of the preparation process of the Hummers method is relatively good and the preparation process is also relatively safe, which is currently the most commonly used one. The present invention improves the original Hummers on the basis of low-temperature intercalation, medium-temperature deep oxidation and high-temperature complete oxidation to prepare graphite oxide. Such as figure 1 As shown, the specific steps are as follows:

[0037] Place a 250ml three-necked flask in an ic...

Embodiment 2

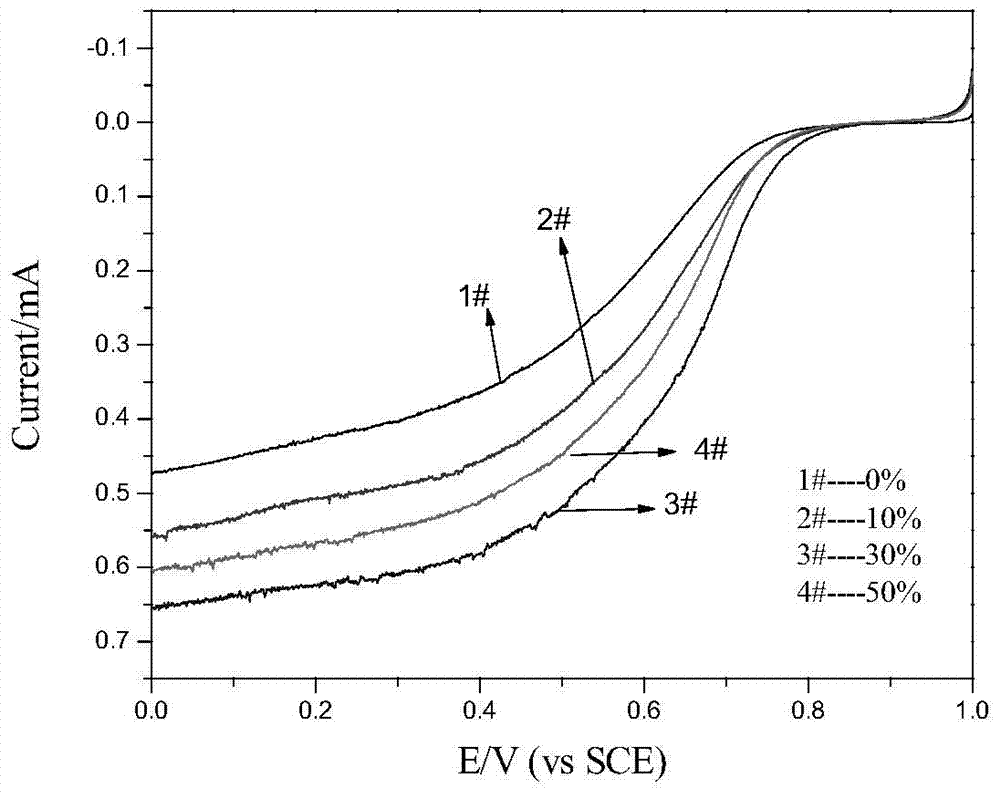

[0048] During the experiment, it was found that adding a small amount of water can change the oxygen reduction performance of the catalyst. For this reason, four sets of reactions were set up to explore the influence of water content on the performance of the catalyst. Under the condition of optimal microwave time, the capacity of adding water is respectively 0%, 10%, 30%, 50% of the total solvent volume (total volume of deionized water and ethylene glycol) to explore the influence of solvent on catalyst performance .

Embodiment 3

[0050] The optimal microwave time obtained in Example 1 and the optimal solvent ratio explored in Example 2 were used to explore the influence of pH value on catalyst performance. The effects of catalysts were explored at pH=4, pH=7, pH=8, pH=9 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com