Austenitic stainless steel pipeline welding process

A technology of austenitic stainless steel and welding technology, which is applied in pipeline systems, welding equipment, manufacturing tools, etc., can solve problems such as poor mechanical properties, difficult control of heat input, and poor welding quality of products, so as to reduce welding stress, It is beneficial to the control of the interlayer temperature and the effect of increasing the welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

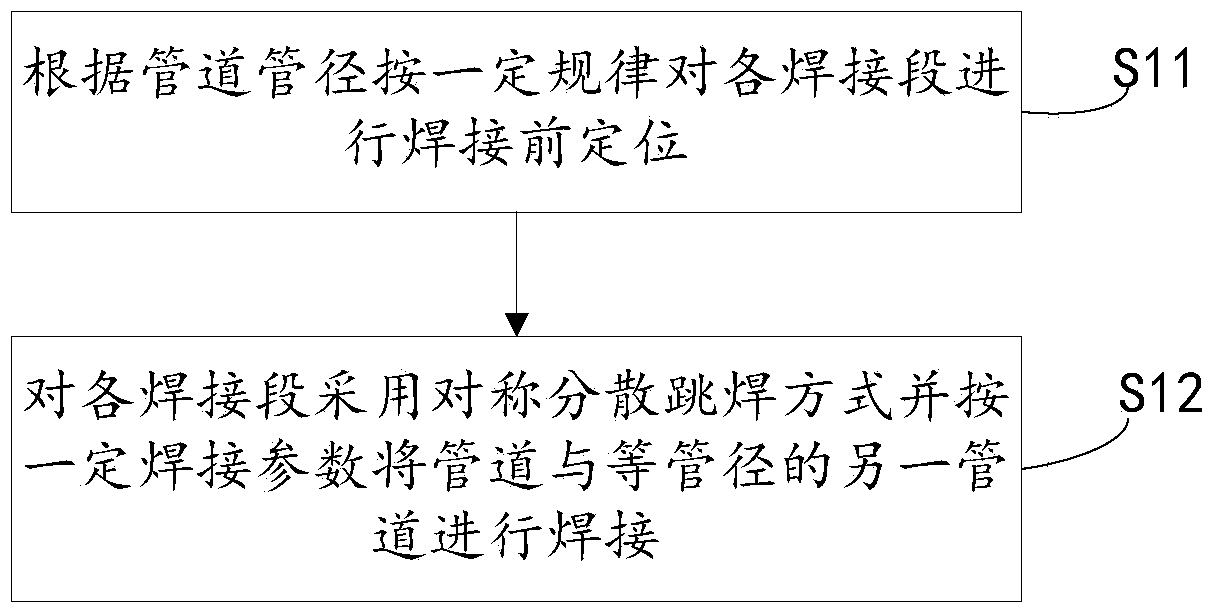

[0025] refer to figure 1 , the embodiment of the austenitic stainless steel pipe welding process of the present invention comprises the following steps:

[0026] Step S11, according to the diameter of the pipeline, the welding joint of the pipeline is positioned before welding according to a certain rule, so as to divide it into several welding sections. Wherein, the part between two adjacent positioning points is defined as a welding segment. The arc lengths of each welding section should be approximately equal, preferably equal, so that the welding will be relatively neat.

[0027] In step S11, it is possible to divide the pipe weld joints into four large welding areas corresponding to each quadrant by dividing the quadrants according to the vertical coordinate system. It is convenient and quick to locate the area and divide it into several welding sections.

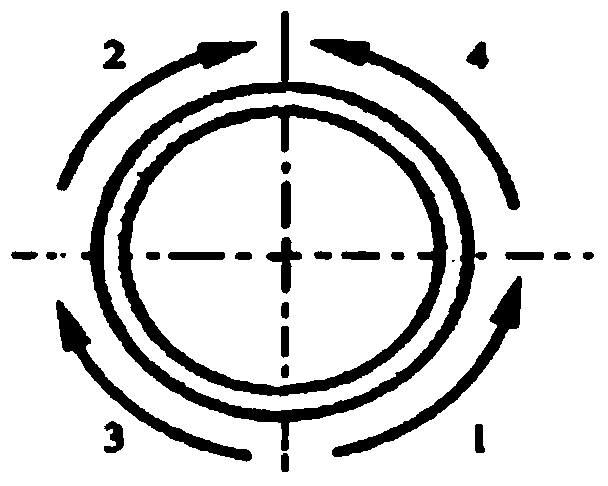

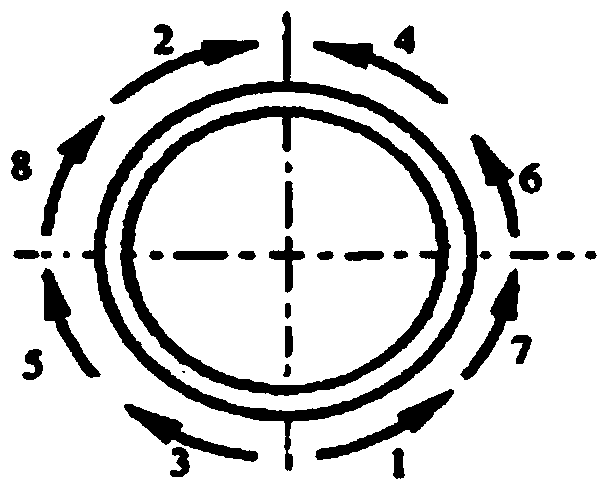

[0028] Specifically, as figure 2 , when the pipe diameter d≤89mm, each welding area has only one welding sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com