Antisludging agent for hot method during sea water desalination

A technology of antiscalant and thermal method, which is applied in seawater treatment, descaling and water softening, chemical instruments and methods, etc., and can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Select raw materials by weight percentage

[0030] Deionized water 38.5%

[0031] Isopropanol 5%

[0032] Benzotriazole 1%

[0033] Hydrolyzed Polymaleic Anhydride 25%

[0034] Ethylenediaminetetramethylenephosphonic acid 7.5%

[0035] Carboxyethylthiosuccinate 3%

[0036] Sodium styrene sulfonate-acryloyl morpholine copolymer 20%

[0037] Add 38.5% deionized water to the reactor; then add 5% isopropanol to the reactor, mix and stir for 10 to 20 minutes; add 1% benzotriazole to the stirred solution, and Stir for 20-60 minutes; add 25% hydrolyzed polymaleic anhydride to the stirred solution, and stir for 10-30 minutes; add 7.5% ethylenediamine tetramethylene phosphonic acid to the stirred solution , and stir for 5 to 15 minutes; add 3% hydroxyethyl thiosuccinic acid to the above stirred solution, and stir for 5 to 15 minutes; add 20% styrenesulfonic acid to the above stirred solution sodium-acryloyl morpholine copolymer, and stirred for 15 to 45 minutes.

Embodiment 2

[0039] Select raw materials by weight percentage

[0040] Deionized water 36%

[0041] Ethylene glycol 8%

[0042] Tolylbenzotriazole 1%

[0043] Hydrolyzed Polymaleic Anhydride 15%

[0044] Ethylenediaminetetramethylenephosphonic acid 5%

[0045] Carboxyethylthiosuccinate 5%

[0046] Sodium styrene sulfonate-acryloyl morpholine copolymer 30%

[0047] Add 36% deionized water in the reactor; then add 8% ethylene glycol in the reactor, mix and stir for 10 to 20 minutes; add 1% tolyltriazole to the stirred solution, and Stir for 20 to 60 minutes; add 15% hydrolyzed polymaleic anhydride to the above stirred solution, and stir for 10 to 30 minutes; add 5% ethylenediamine tetramethylene phosphonic acid to the above stirred solution , and stirred for 5 to 15 minutes; added 5% hydroxyethyl thiosuccinic acid to the stirred solution, and stirred for 5 to 15 minutes; added 30% styrenesulfonic acid to the stirred solution sodium-acryloyl morpholine copolymer, and stirred for 15 to ...

Embodiment 3

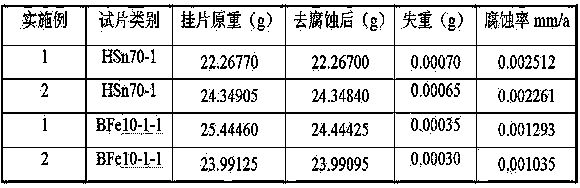

[0048] Example 3 Anti-calcium carbonate scale performance experiment

[0049] The measurement of scale inhibition performance of the present invention adopts seawater concentration of 2 times in Weihai Economic Zone, then adds 250mL of concentrated seawater into a 500mL volumetric flask, and adds 1.0mL of scale inhibitor sample solution (concentration is 5000mg / L) with a pipette. Make the amount of anti-scaling dispersant to 5mg, shake well. Dilute to the mark with sea water and shake well. Place the test solution in a constant temperature water bath at (80±1)°C, place it at a constant temperature for 10 hours, take it out, cool it to room temperature and filter it with a medium-speed filter paper, and titrate the filtrate with a 0.01mol / LEDTA standard solution to determine the residual Ca 2+ Concentration, the scale inhibition rate is calculated according to the following formula:

[0050] Scale inhibition rate = (C 1 -C 2 ) / (C 0 -C 2 )

[0051] where C 1 is the Ca afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com