HRB500 hot-rolled belt rib antiseismic steel bar and preparation method thereof

A technology for hot-rolled ribbed and earthquake-resistant steel bars is applied in the field of iron and steel smelting, which can solve the problems of unqualified rolling performance, increased low-fold defects of cast slabs, and poor welding performance, and achieves excellent welding performance, low production cost, and dispersion. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

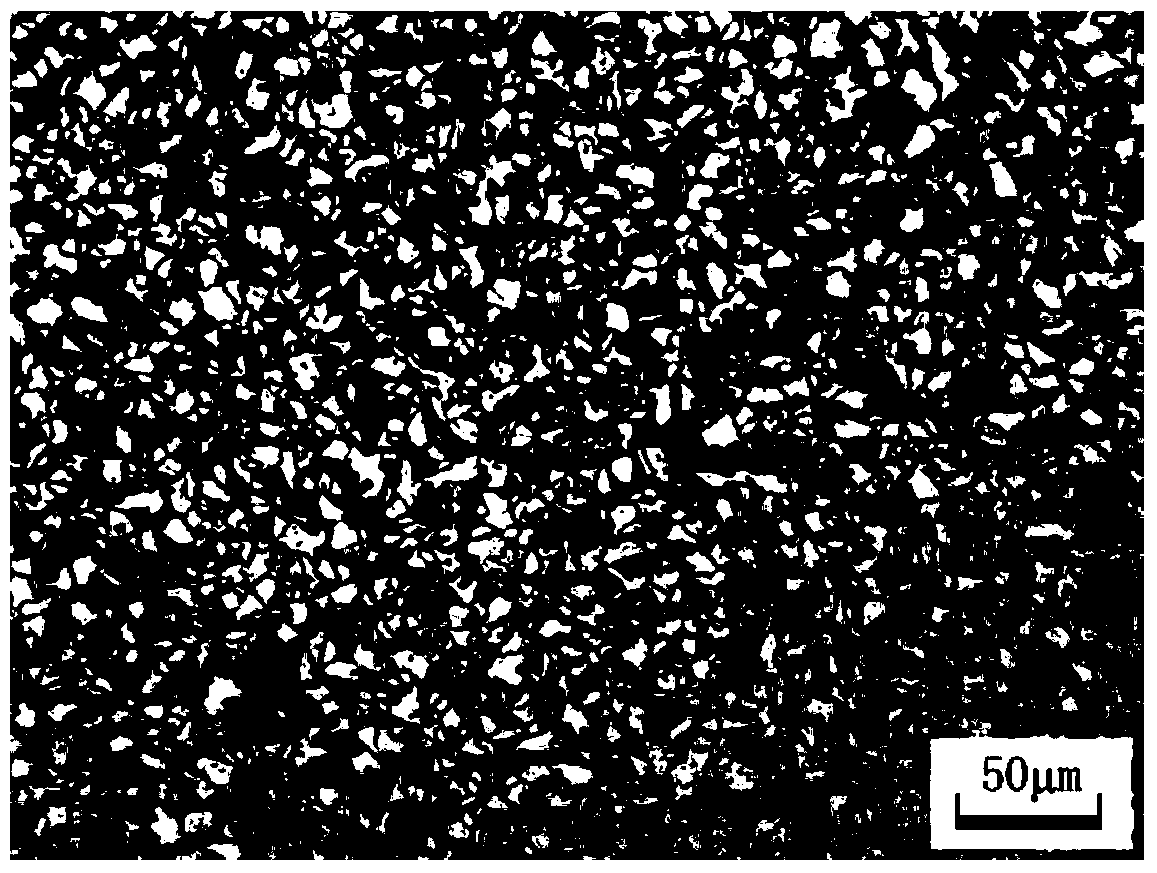

Image

Examples

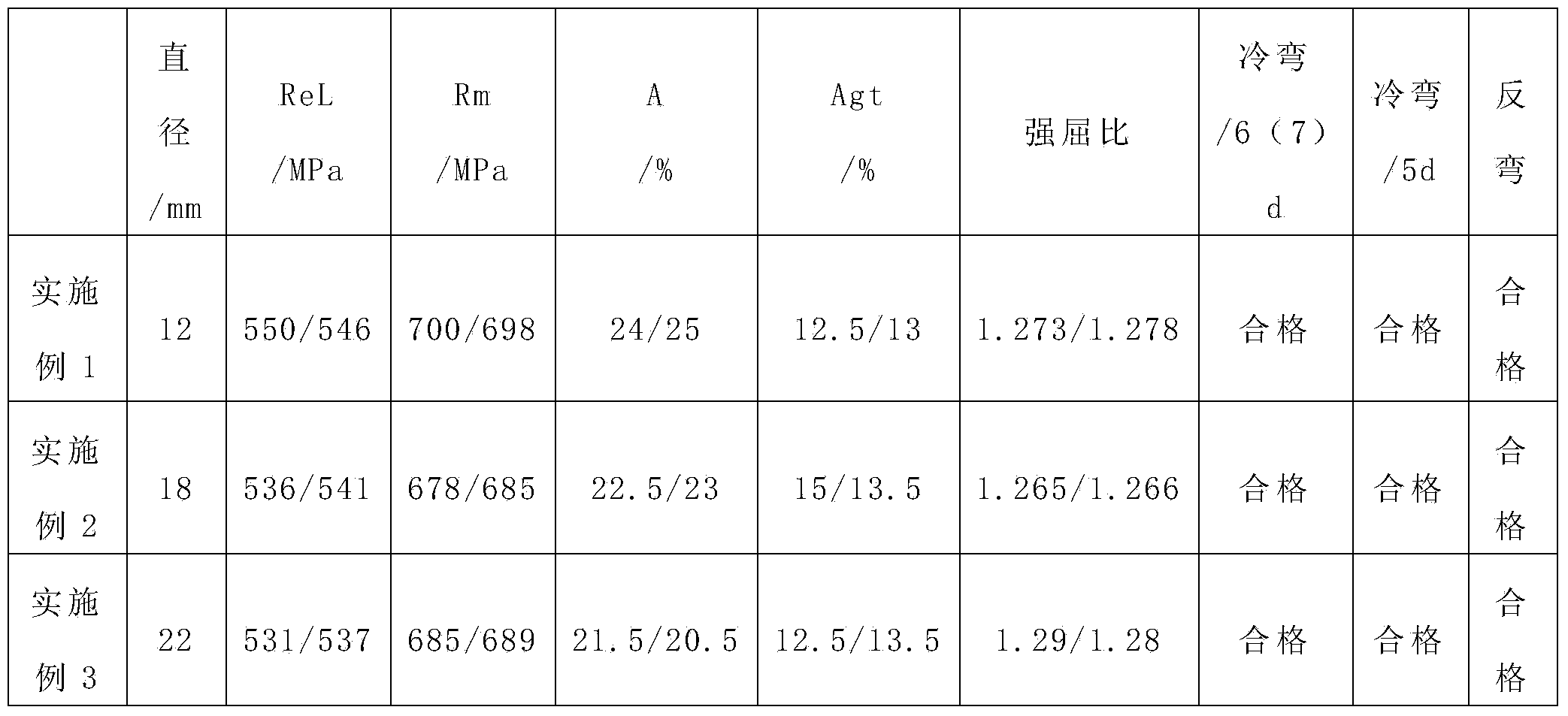

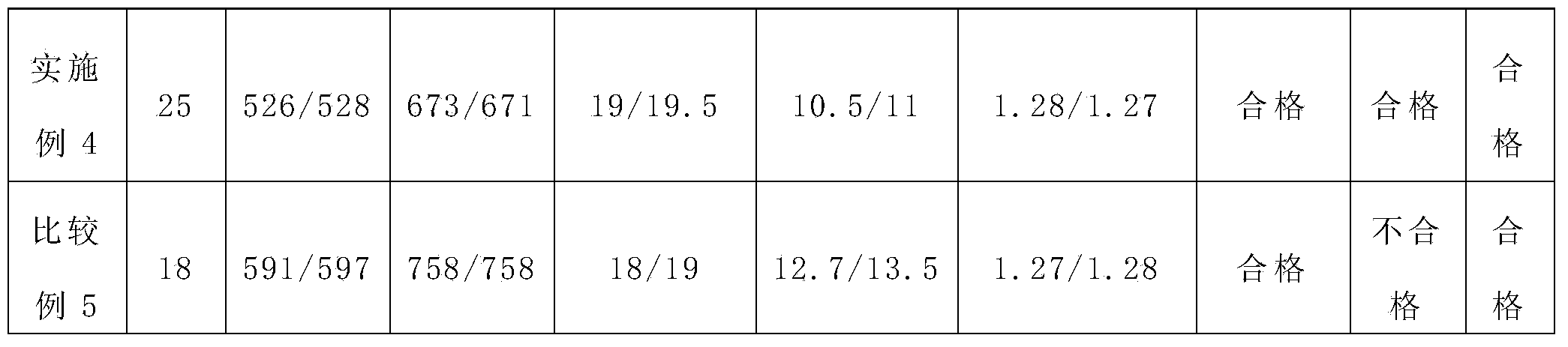

Embodiment 1

[0021] Prepare a HRB500 grade hot-rolled ribbed anti-seismic steel bar with a diameter of 12mm. The chemical composition of molten steel is calculated by weight percentage: C: 0.17%, Si: 0.45%, Mn: 1.27%, P: 0.031%, S: 0.024 %, V: 0.029%, N: 0.0087%.

[0022] Its preparation method comprises the following steps in turn:

[0023] The steps of hot metal desulfurization, converter smelting, argon blowing, continuous casting, billet heating, rolling, post-rolling controlled cooling, and cooling bed air cooling, wherein,

[0024] The hot metal desulfurization adopts the magnesium powder desulfurization process, and the sulfur content of the outgoing hot metal is controlled to S≤0.030%, and the desulfurization slag in the tank is cleaned;

[0025] During converter smelting, the loading amount of steel scrap accounts for 10% of the total loading amount; the final slag basicity target is 2.8; the end point C of the converter is controlled at 0.07%; the tapping temperature is 1700°C; ...

Embodiment 2

[0031] A HRB500 grade hot-rolled ribbed anti-seismic steel bar with a diameter of 18 mm was prepared. The chemical composition of molten steel was calculated as follows: C: 0.21%, Si: 0.57%, Mn: 1.36%, P: 0.034%, S: 0.027%, V: 0.033%, N: 0.0095%;

[0032] Its preparation method comprises the following steps in turn:

[0033] The steps of hot metal desulfurization, converter smelting, argon blowing, continuous casting, billet heating, rolling, post-rolling controlled cooling, and cooling bed air cooling, wherein,

[0034] The hot metal desulfurization adopts the magnesium powder desulfurization process, and the sulfur content of the outgoing hot metal is controlled to S≤0.030%, and the desulfurization slag in the tank is cleaned;

[0035] During converter smelting, the amount of steel scrap charged accounts for 12% of the total amount charged; the final slag basicity target is 3.0; the end point C of the converter is controlled at 0.07%; the tapping temperature is 1695°C; the ...

Embodiment 3

[0041] Prepare a HRB500 grade hot-rolled ribbed anti-seismic steel bar with a diameter of 22mm. According to the steel composition requirements, the chemical composition of molten steel is: C: 0.23%, Si: 0.65%, Mn: 1.47%, P: 0.034%, S: 0.021% , V: 0.045%, N: 0.0129%;

[0042] Its preparation method comprises the following steps in turn:

[0043] The steps of hot metal desulfurization, converter smelting, argon blowing, continuous casting, billet heating, rolling, post-rolling controlled cooling, and cooling bed air cooling, wherein:

[0044] The hot metal desulfurization adopts the magnesium powder desulfurization process, and the sulfur content of the outgoing hot metal is controlled to S≤0.030%, and the desulfurization slag in the tank is cleaned;

[0045] During converter smelting, the amount of steel scrap charged accounts for 12% of the total amount charged; the final slag basicity target is 3.0; the end point C of the converter is controlled at 0.07%; the tapping temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com