Construction method of shield passing through railway yard

A railway station yard and construction method technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of surrounding building pipelines, station safety threats, shield tunnel construction difficulties, and excessive ground subsidence , to achieve the effects of avoiding later settlement, reducing soil disturbance, and small soil displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A construction method for shield tunneling across railway yards, comprising the following steps:

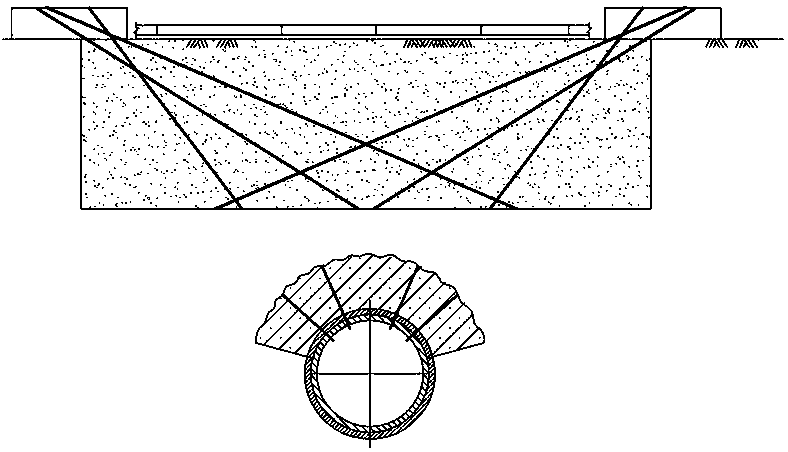

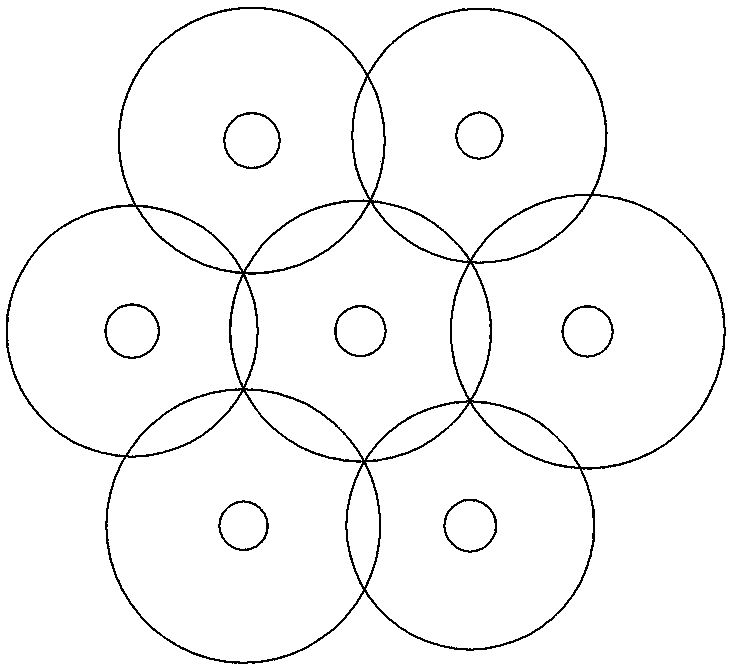

[0021] A number of inclined grouting holes extending to the bottom of the railway line are drilled from both sides of the railway platform. Sleeve valve pipes are inserted into each grouting hole to simultaneously grout and reinforce the railway subgrade. The reinforcement depth is 4m below the rail bottom. The grouting holes on one side are arranged in a quincunx shape, and the expansion radii of the grout injected into adjacent grouting holes through the sleeve valve pipe partially overlap each other, so that the expanded grout can be co-connected, as shown in figure 2 . The grouting holes on both sides are parallel and staggered at the bottom, and the expansion radii of the grout injected through the sleeve valve pipe in the grouting holes on both sides partially overlap with each other, so that the expanded grout on both sides can be co-connected to form a three-dimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com