Welding type LED substrate and manufacturing technology thereof

A technology of LED substrate and manufacturing process, which is applied in the direction of lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of small thermal conductivity of thermal paste, unsatisfactory heat dissipation effect, and failure to achieve joint surface, etc., to achieve production High efficiency, significant social significance and economic benefits, high production efficiency and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

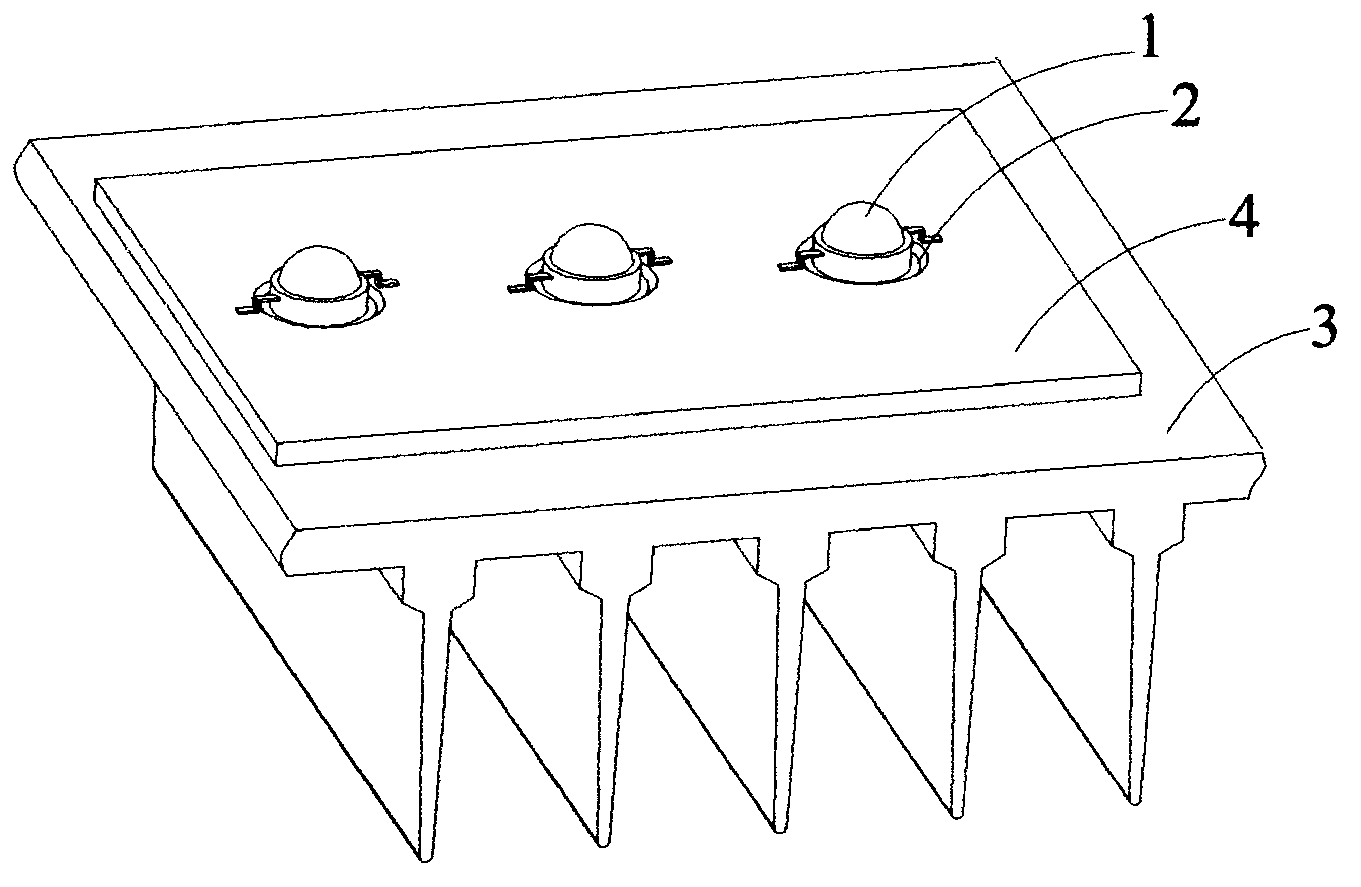

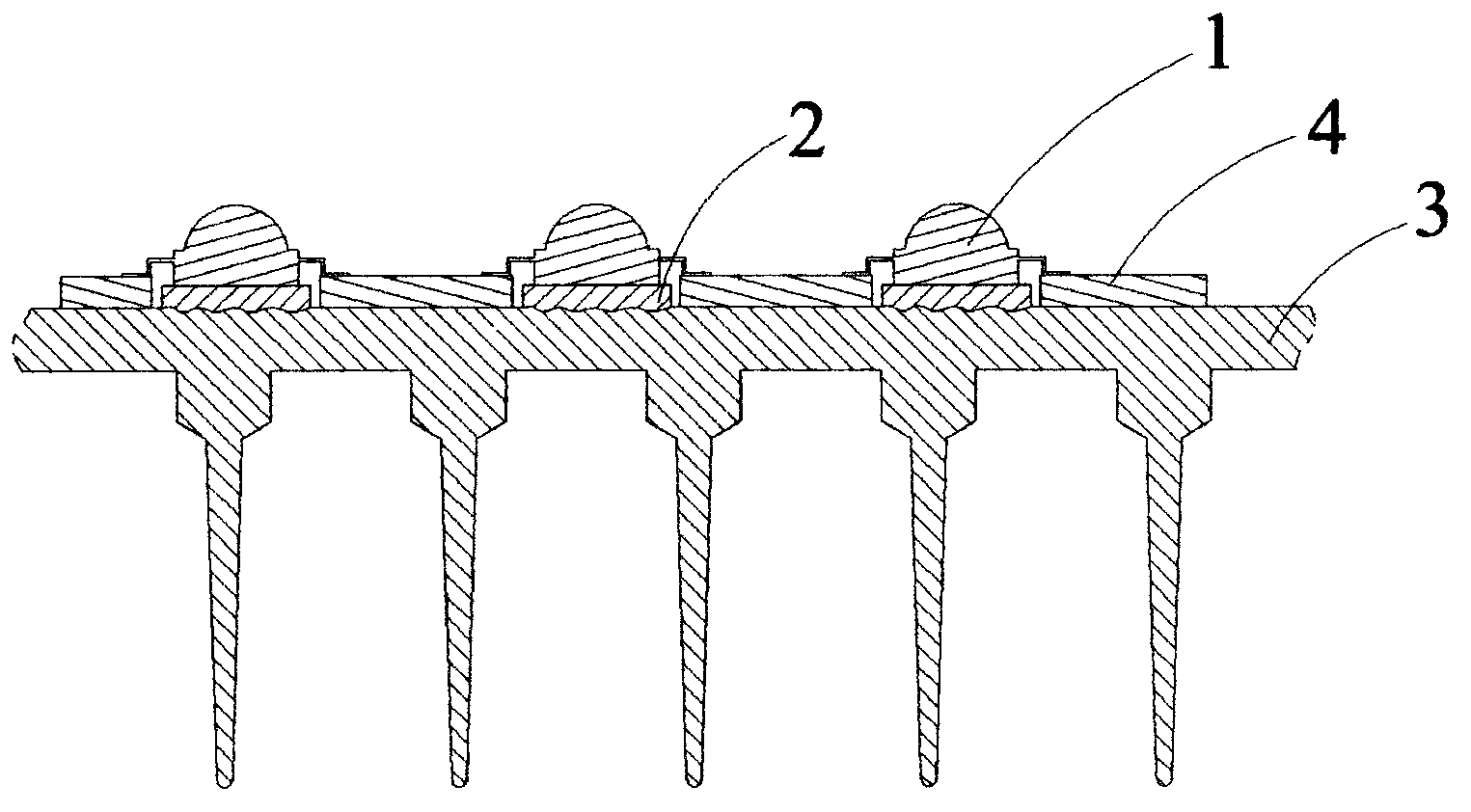

[0025] Such as figure 1 , figure 2 As shown, this embodiment is mainly composed of LED light source 1, metal layer 2, substrate 3, PCB board 4 and other components. Among them, the metal layer 2 is thermally sprayed on the surface of the substrate 3, and the PCB board 4 is installed on the surface of the metal layer 2 and the substrate 3. There are many openings in the middle of the PCB board 4, and the aperture is slightly larger than the size of the bracket of the LED light source 1. The LED The light source 1 is installed in the opening of the PCB 4 and welded on the metal layer 2 , and the pins at both ends of the LED light source 1 are welded on the PCB 4 to form a connection with the circuit distribution on the PCB 4 .

[0026] During the spraying process of the metal layer 2, for the selection of the thermal spraying position on the surface of the substrate 3, local fixed-point spraying or full spraying can be adopted. All thermal spraying is adopted. On the one hand...

Embodiment 2

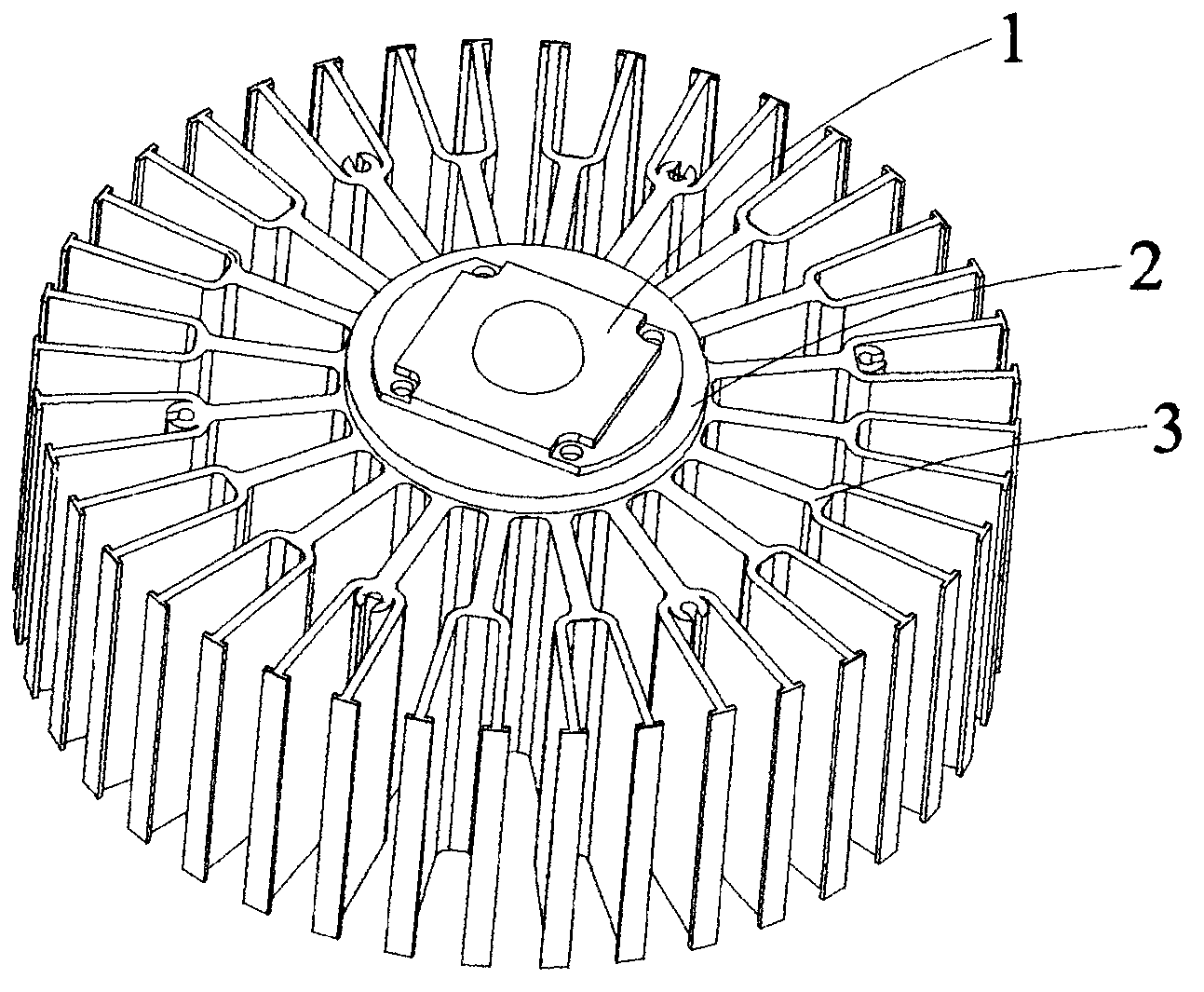

[0037] Such as image 3 and Figure 4 , this preferred embodiment is mainly composed of LED light source 1, metal layer 2, substrate 3 and so on. Wherein, the base plate 3 adopts an aluminum alloy heat sink with a structure similar to a sunflower, and the central part is a solid cylinder with cooling fins radially distributed around the cylinder. The metal layer 2 is thermally sprayed on the entire cylinder plane on the substrate 3 , and the integrated packaged LED light source 1 is welded on the surface of the metal layer 2 .

[0038] As the main part of heat dissipation, the substrate 3 can be changed according to actual application needs. It can be considered that the surface of the component that plays a role in heat dissipation can be used as the substrate 3 for thermal spraying of the metal layer 2 on the surface. The substrate 3 in this implementation adopts a heat sink similar to a sunflower structure. On the one hand, it has a wide range of applications and can be u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com