Air energy heat pump heat supply and heating system with water tank inside

An air energy heat pump and heating system technology, applied in hot water central heating system, heating system, space heating and ventilation, etc., can solve the problem of inability to meet human needs, lack of intelligent control, long time required, etc. problems, to achieve the effect of realizing networked intelligent remote control, meeting humanized needs, and facilitating production and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

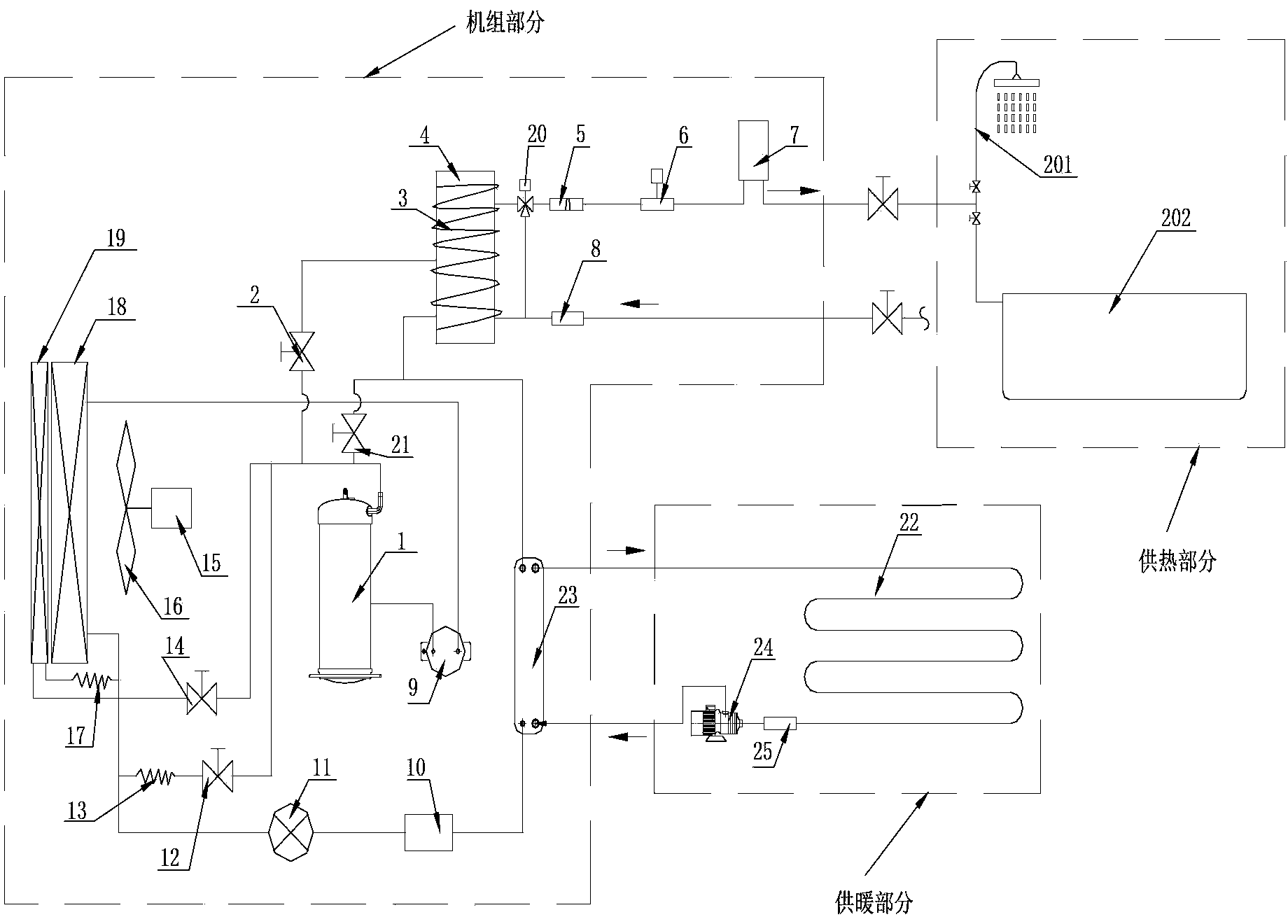

[0028] see figure 1 , is a schematic diagram of a heating and heating system with a built-in water tank air source heat pump in the first embodiment of the present invention. The built-in water tank air source heat pump heating and heating system includes a unit part, a heating part, a heating part and an intelligent control part. The unit The part includes the air energy heat pump heating part, the electric heating part, the water pipe part and the control circuit part.

[0029] The control circuit part is used to start the compressor to supply heat according to the detected temperature of the small-capacity water tank when the temperature is lower than the start-up temperature difference of the compressor. The circuit part is also used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com