Air compressor unit networking control system of PROFIBUS bussing technique

An air compressor unit and networked control technology, which is applied in the transmission system, electrical program control, program control in sequence/logic controller, etc., can solve the problem of unstable transmission of "massive" data communication and networked control of air compressor units The equipment of the system is expensive, lack of safety and stability, etc., to achieve the effect of overcoming the lack of stability, ensuring safety, stability, high stability and safety requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

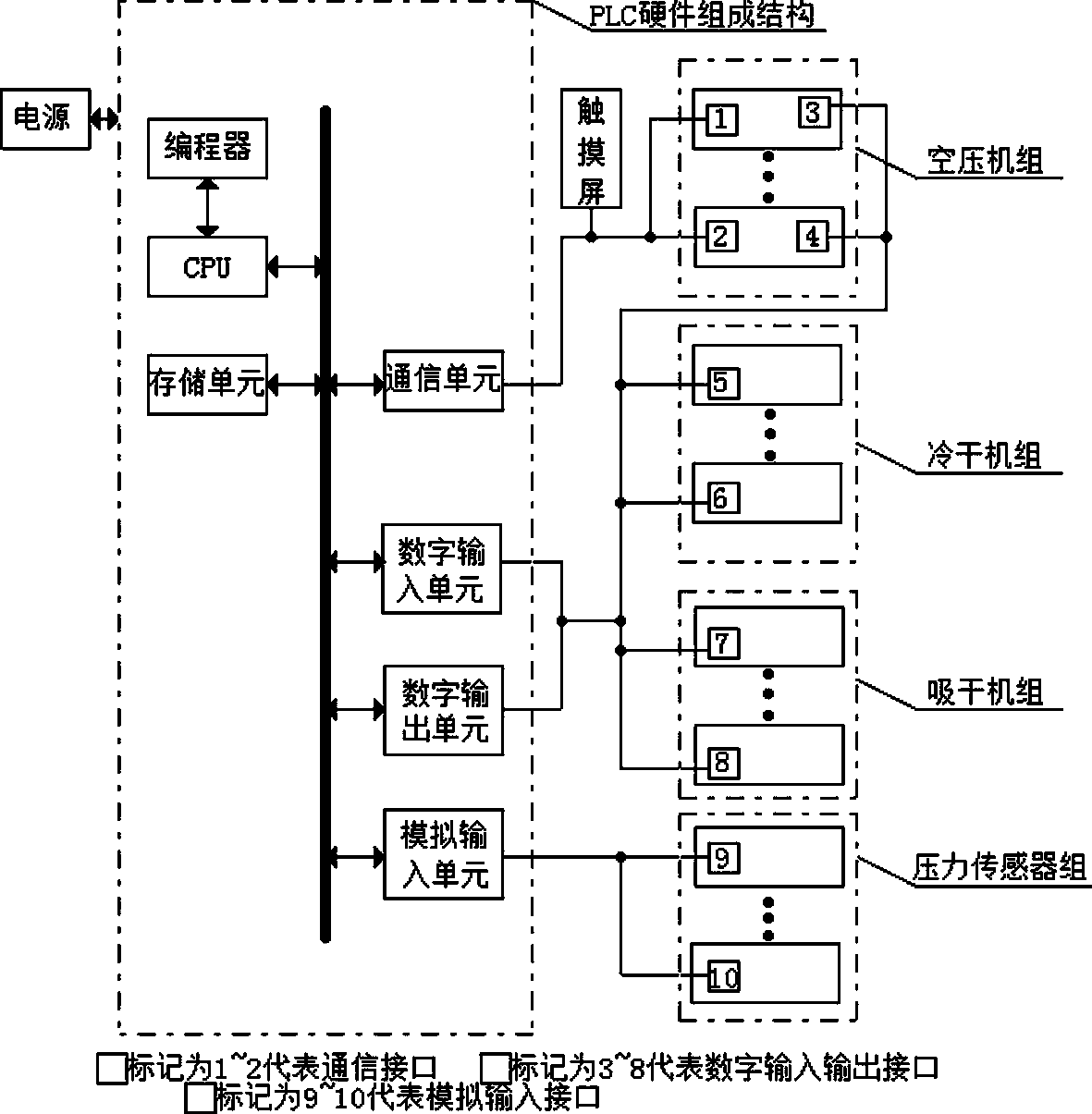

[0075] A networked control system for air compressors based on PROFIBUS technology. The air compressor unit networking control system such as figure 1 Shown: Including PLC control module, touch screen, air compressor unit, air dryer unit, suction dryer unit, pressure sensor and power supply. The control module PLC is composed of power supply unit, micro-control CPU unit, communication unit, memory, analog input unit, digital input unit, digital output unit, and programmer; the power supply unit is connected with micro-control CPU unit, communication unit, memory, and analog input unit respectively , digital input unit, digital output unit, connected to the power port of the programmer; the programmer is connected to the micro-controlling CPU unit; memory, communication unit, analog input unit, digital input unit, and digital output unit are respectively connected to the CPU through the data bus; touch screen Connect with the communication unit in the control module PLC.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com