Control method for servo control mechanical arm and visual inspection production line and mechanical arm

A robotic arm and visual inspection technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of low degree of automation, high scrap rate, slow efficiency, etc., to achieve automatic production, high-efficiency detection and classification The effect of placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

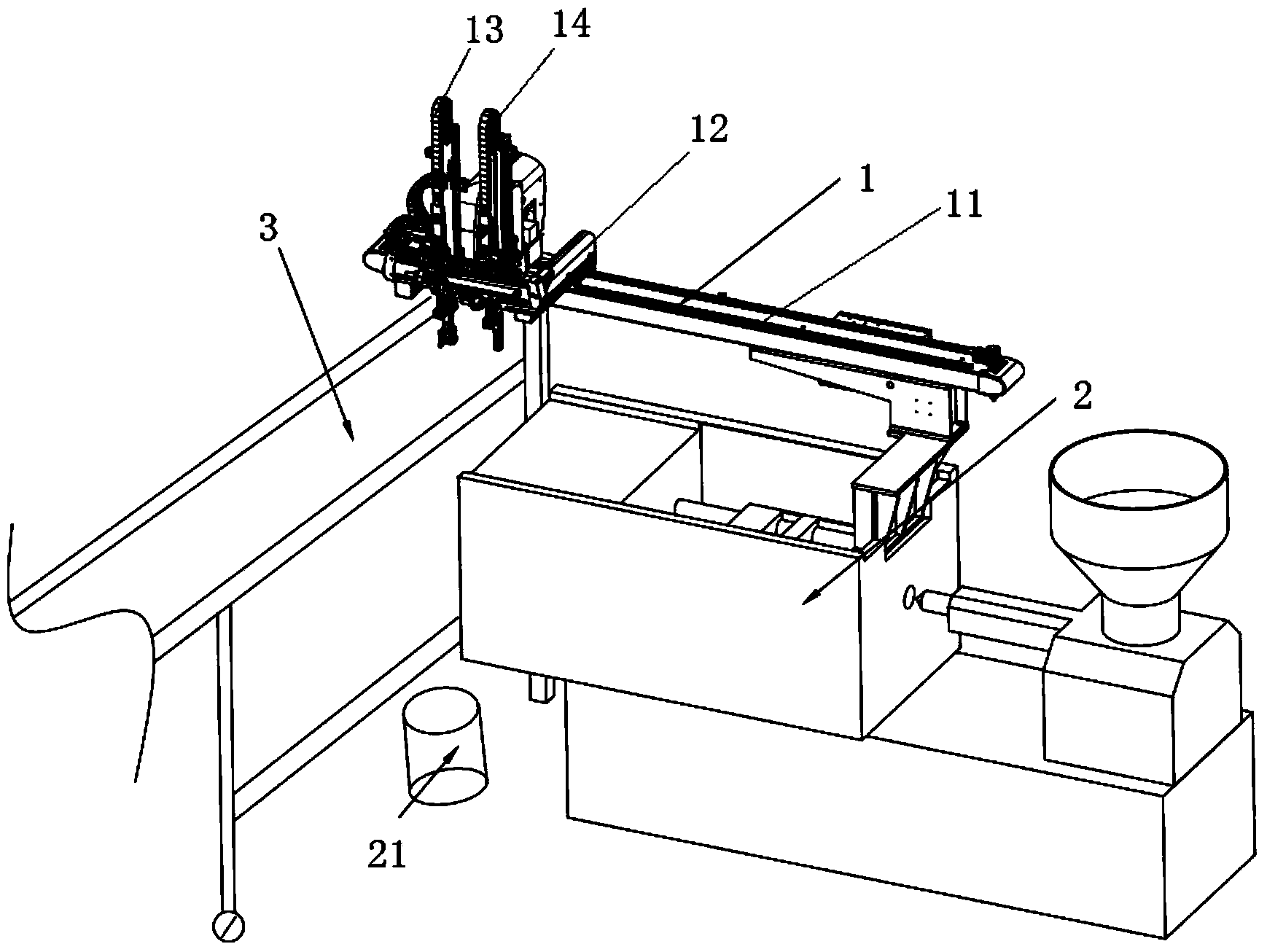

[0036] Examples, see figure 1 , the servo control manipulator provided in this embodiment and the control method of the visual inspection production line, it includes a plurality of mechanical arms 1 arranged on a production line conveyor belt 3, on which the mechanical arm 1 is provided with a horizontal part 11, a drawing part 12 1. The positive arm portion 13 and the secondary arm portion 14 are driven by the servo motor to move in translation. The positive arm portion 13 and the secondary arm portion 14 are arranged on the drawing portion 12, and the drawing portion 12 is arranged on the horizontal portion 11. Servo control and Centralized management and decentralized control system for visual inspection. The control system is connected to multiple robotic arm servo control systems and visual inspection systems through the CAN control bus, which includes the following steps:

[0037] (1) The control system includes a central control processor;

[0038] (2) The control sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com