Lithium ion battery negative material structure and preparation method thereof

A technology of lithium ion battery and negative electrode material, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of particle crushing, volume expansion, pulverization, etc., and achieve the effect of good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

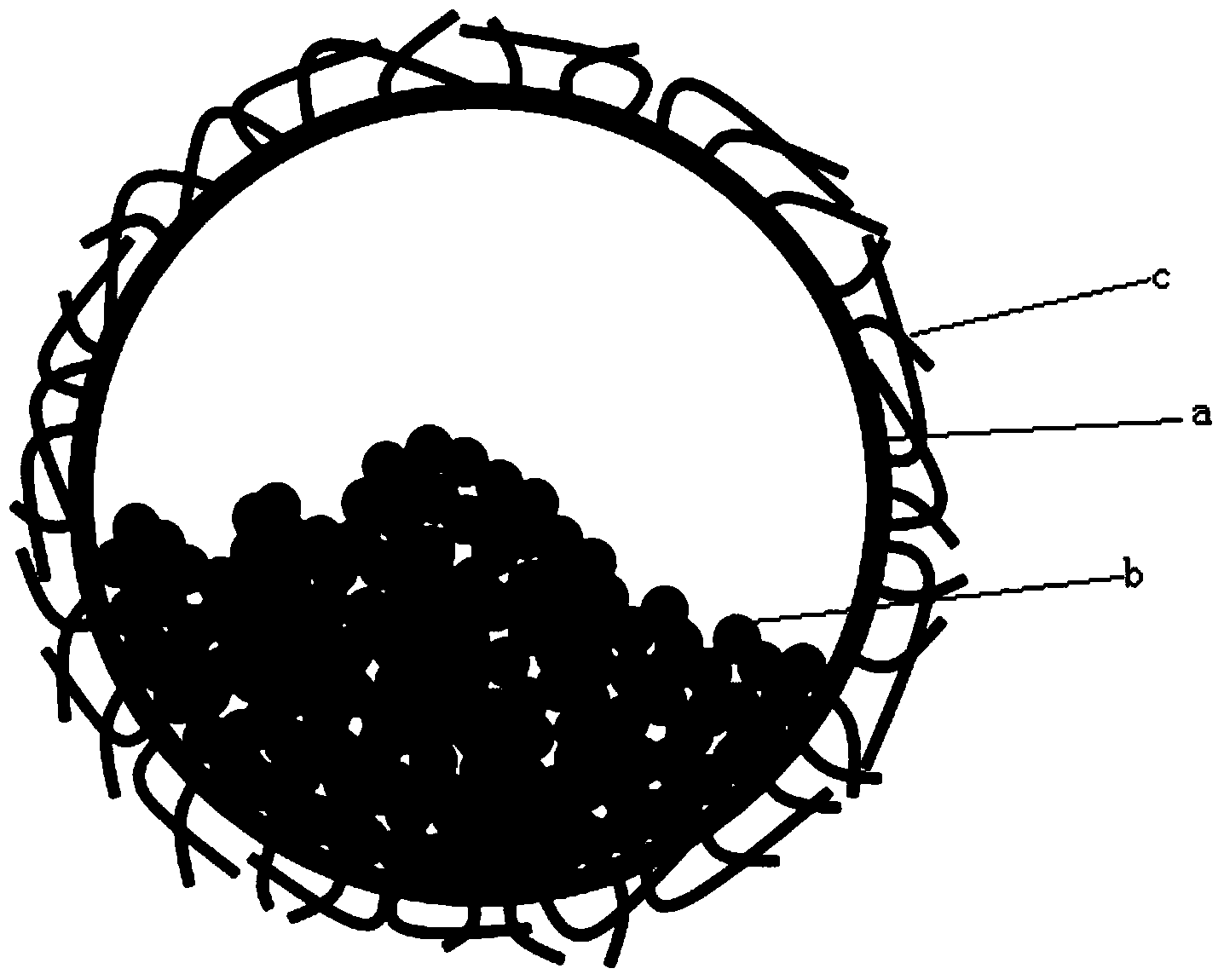

[0026] Specific Embodiment 1: In this embodiment, the structure of a negative electrode material for a lithium ion battery is a hollow pomegranate structure wrapped with one-dimensional linear carbon, the outer structure is one-dimensional linear carbon, and the inner structure is an empty pomegranate structure.

[0027] The lithium-ion battery negative electrode material of this embodiment is characterized in that: the entire particle size is micron or submicron, the external structure is one-dimensional linear carbon, and the internal structure is a hollow pomegranate structure; inside the particle, there are many silicon particles with a diameter of about 10 nm. Accumulate to form the core of the hollow pomegranate structure, and the 5-100nm thick carbon layer forms the shell of the hollow pomegranate structure. One side of the core is in contact with the carbon shell, and the other side is an empty volume; outside the particle, many one-dimensional lines are buried on the ca...

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the hollow pomegranate structure in the structure of the negative electrode material of the lithium ion battery is composed of a core formed by silicon particles and a shell composed of a carbon layer. Dimensional linear carbon is embedded on the shell, in which the diameter of silicon particles is 8-15nm, and the thickness of the carbon layer is 5-100nm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the core formed by the accumulation of silicon particles occupies 10% to 80% of the volume of the pomegranate structure. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com