Silver/N,N-dimethylaniline modified nano silicon dioxide antibacterial material and preparation method thereof

A technology of nano-silica and dimethylaniline, applied in the field of nano-materials, can solve the problems of reduced antibacterial effect, high surface potential energy, and easy aggregation of nano-silver antibacterial materials, so as to prevent agglomeration and improve antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of modified silica: Mix 120 μL of mercaptopropylmethyldimethoxysilane and 150 μL of 35% NH 4 OH was added to the ethanol solution in which 200mg of silicon dioxide was dissolved, the solution was stirred at room temperature for 20 hours, then centrifuged and washed, and dried in an oven at 25°C for 5 hours;

[0028] (2) Dissolve 100 mg of the above-mentioned modified silica in ethanol solution, disperse ultrasonically for 20 minutes and heat to 60°C, then add 62 mg of silver nitrate solution and stir for 4 hours;

[0029] (3) Add 15.6 mg of N,N-dimethylaniline into the solution of (2), stir for 12 hours, centrifuge, wash and dry to obtain silver / N,N-dimethylaniline modified nano-silica antibacterial material.

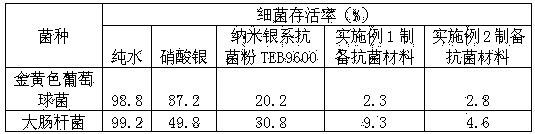

[0030]

Embodiment 2

[0032] (1) Preparation of modified silica: mix 140 μL of mercaptopropylmethyldimethoxysilane and 120 μL of 45% NH 4 OH was added to the ethanol solution in which 200mg of silicon dioxide was dissolved, the solution was stirred at room temperature for 10 hours, then centrifuged and washed, and dried in an oven at 28°C for 8 hours;

[0033] (2) Dissolve 100 mg of the above-mentioned modified silicon dioxide in ethanol solution, disperse ultrasonically for 15 minutes and heat to 50°C, then add 50 mg of silver nitrate solution and stir for 3 hours;

[0034] (3) Add 14.2 mg of N,N-dimethylaniline, stir for 18 hours, centrifuge, wash and dry to obtain the silver / N,N-dimethylaniline modified nano-silica antibacterial material.

[0035]

Embodiment 3

[0037] (1) Preparation of modified silica: Mix 100 μL of mercaptopropylmethyldimethoxysilane and 100 μL of 20% NH 4 OH was added to the ethanol solution in which 200mg of silicon dioxide was dissolved, the solution was stirred at room temperature for 10 hours, then centrifuged and washed, and dried in an oven at 20°C for 10 hours;

[0038] (2) Dissolve 100 mg of the above-mentioned modified silicon dioxide in an ethanol solution, ultrasonically disperse for 10 minutes, heat to 40°C, add 34 mg of silver nitrate solution, and stir for 2 hours;

[0039] (3) Add 12.1 mg of N,N-dimethylaniline, stir for 10 hours, centrifuge, wash and dry to obtain the silver / N,N-dimethylaniline modified nano-silica antibacterial material.

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com