A method for preparing non-trans fatty acid pre-sent non-dairy cream

A plant-based cream and zero-trans technology, applied in the production/processing of edible oil/fat, food science, etc., can solve problems such as unstable network structure, high solid fat content, rough air bubbles, etc., and achieve stability and operation Good sex, maintain taste and texture, easy to eat and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

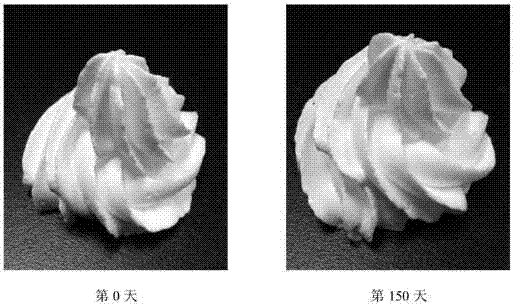

Embodiment 1

[0016] Zero trans fatty acid pre-whipped non-dairy cream formula 1: extremely hydrogenated palm kernel oil 220g (the fatty acid composition is shown in Table 1), white sugar 120g, corn syrup 60g, sodium caseinate 10g, sucrose fatty acid ester 5g, soluble soybean polysaccharide 3g, hydroxypropyl starch 6g, polyglycerol ricinoleate 5g, hydroxypropyl methylcellulose 2g, acetate starch 5g, acetylated distarch adipate 3g, propylene glycol alginate 3g, gellan gum 2g, Edible salt 3g, dipotassium hydrogen phosphate 0.5g, sodium dihydrogen phosphate 0.5g, vanillin 0.5g.

[0017] Preparation process: Melt extremely hydrogenated palm kernel oil at 60°C, dissolve white sugar and corn syrup in 350g water, heat to 60°C, add sodium caseinate, sucrose fatty acid ester, soluble soybean polysaccharide, Hydroxypropyl starch, polyglyceryl ricinoleate, hydroxypropyl methylcellulose, starch acetate, acetylated distarch adipate, propylene glycol alginate, gellan gum, edible salt, dipotassium hydroge...

Embodiment 2

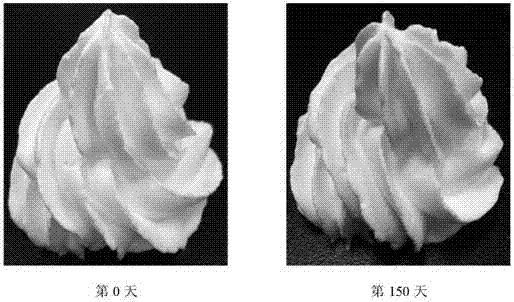

[0021] Zero trans fatty acid pre-whipped non-dairy cream formula 2: extremely hydrogenated cottonseed oil 100g, extremely hydrogenated palm kernel oil 150g, white sugar 100g, corn syrup 65g, sodium caseinate 12g, sucrose fatty acid ester 6g, soluble soybean polysaccharide 4g, Hydroxypropyl starch 3g, polyglycerol ricinoleate 7g, hydroxypropyl methylcellulose 2g, acetate starch 5g, acetylated distarch adipate 3g, propylene glycol alginate 4g, gellan gum 5g, edible salt 2 g, 0.5 g of dipotassium hydrogen phosphate, 0.5 g of sodium dihydrogen phosphate, and 0.5 g of vanillin.

[0022] Preparation process: Melt extremely hydrogenated cottonseed oil and palm kernel oil at 60°C, dissolve white sugar and corn syrup in 350g water, heat to 60°C, add sodium caseinate, sucrose fatty acid ester, soluble Soybean polysaccharide, hydroxypropyl starch, polyglycerol ricinoleate, hydroxypropyl methylcellulose, acetate starch, acetylated distarch adipate, propylene glycol alginate, gellan gum, e...

Embodiment 3

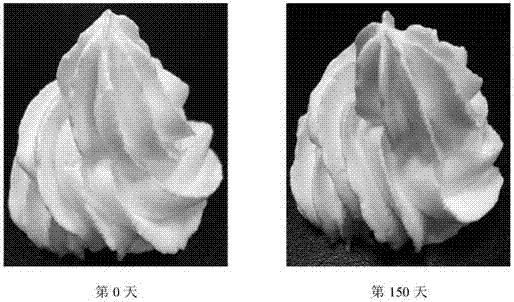

[0024] Zero trans fatty acid pre-whipped non-dairy cream formula three: extreme hydrogenated soybean oil 40g, extreme hydrogenated coconut oil 100g, extreme hydrogenated palm kernel oil 100g, white sugar 130g, corn syrup 70g, sodium caseinate 15g, sucrose fatty acid ester 8g , soluble soybean polysaccharide 5g, hydroxypropyl starch 2g, polyglycerol ricinoleate 6g, hydroxypropyl methylcellulose 3g, acetate starch 6g, acetylated distarch adipate 2g, propylene glycol alginate 6g, knot Cold gum 5g, edible salt 3g, dipotassium hydrogen phosphate 0.5g, sodium dihydrogen phosphate 0.5g, vanillin 0.5g.

[0025] Preparation process: Melt extremely hydrogenated soybean oil, coconut oil and palm kernel oil at 60°C, dissolve white sugar and corn syrup in 350g of water, heat to 60°C, add sodium caseinate, sucrose fat under stirring Ester, soluble soybean polysaccharide, hydroxypropyl starch, polyglycerol ricinoleate, hydroxypropyl methylcellulose, acetate starch, acetylated distarch adipat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com